Condition Monitoring

Maximizing Your Investment Value Through Smart Monitoring

In today's industrial landscape, maintenance strategy plays a crucial role in operational reliability. NSK's advanced condition monitoring solutions deliver guaranteed return on investment and reduced life-cycle costs by preventing unplanned downtime and optimizing equipment performance. What is condition monitoring? - Condition Monitoring is a method to determine the condition of machines internal components such as bearings and gears whilst the machine is operating.

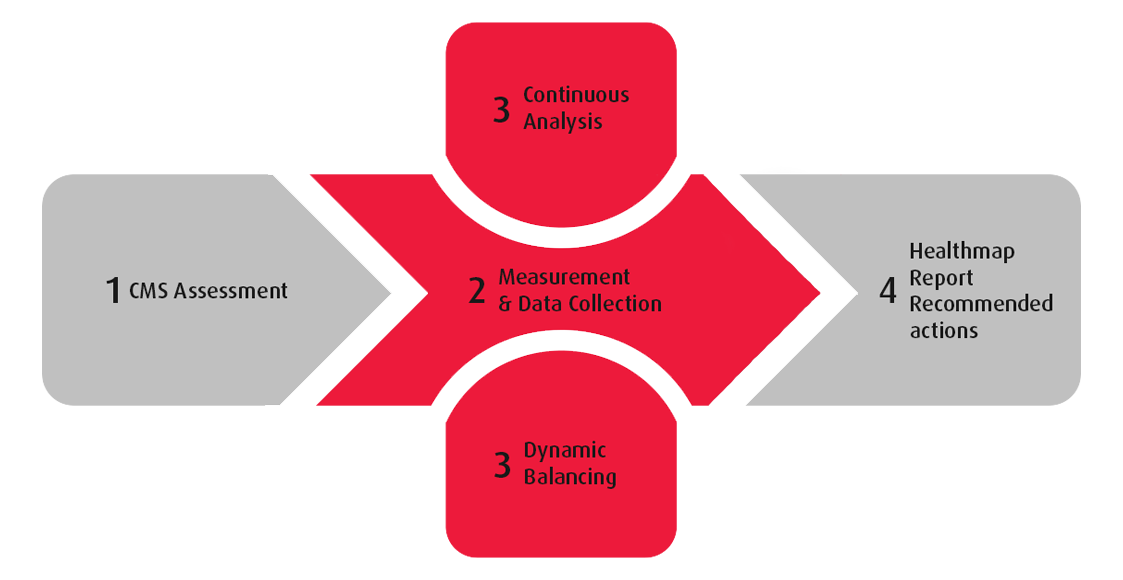

Our CMS Process

Holistic Monitoring

Our sophisticated monitoring system provides:

- Real-time performance tracking

- Comprehensive gear monitoring

- Advanced bearing diagnostics

- Blade pitch and yaw monitoring

- Total system prognostic data

Intelligent Data Management

The VibroSuite package delivers:

- Market-leading diagnostics

- Advanced data mining capabilities

- Remote data processing

- Strategic maintenance planning

- Comprehensive analytics tools

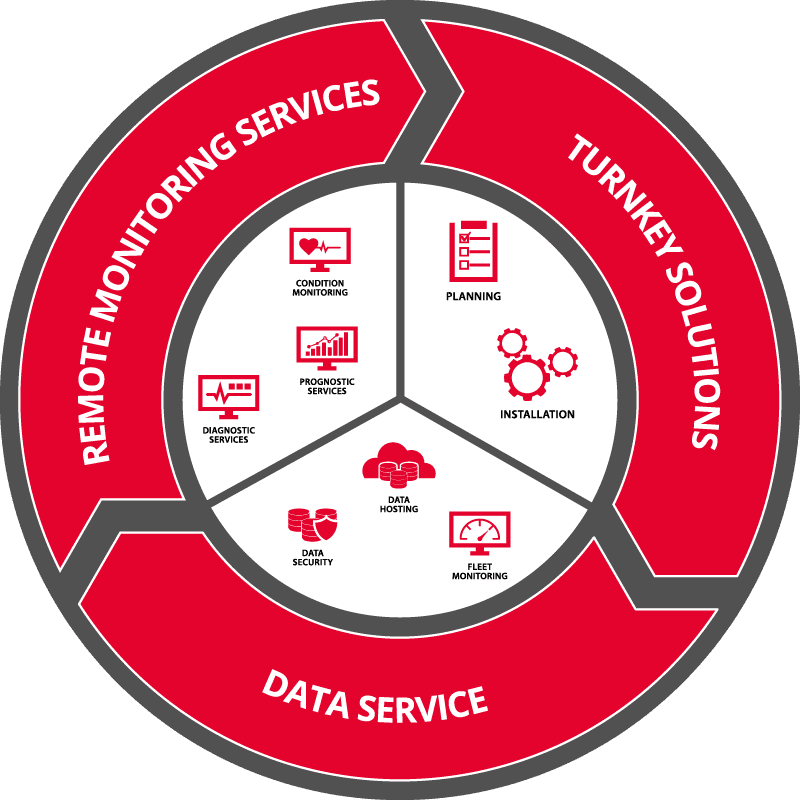

360º Service Coverage

1. Turnkey Solutions

- Complete system integration

- Customized implementation

- Full technical support

3. Remote Monitoring Services

- 24/7 surveillance

- Immediate issue detection

- Expert analysis

- Proactive maintenance recommendations

2. Data Services

- Real-time monitoring

- Advanced analytics

- Trend analysis

- Performance reporting

NSK's Comprehensive Monitoring Solutions

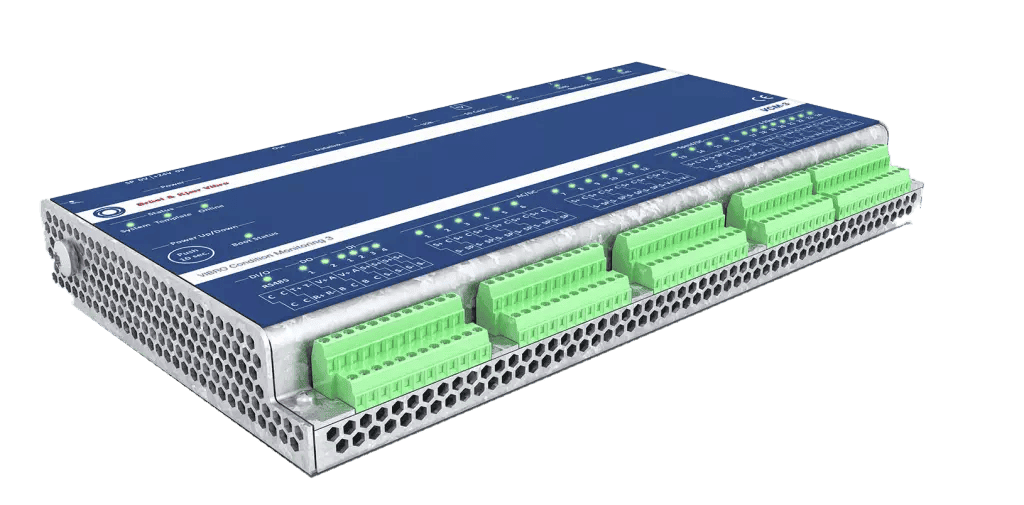

As part of our commitment to providing comprehensive solutions, NSK's condition monitoring capabilities are enhanced through Brüel & Kjær Vibro (B&K Vibro), a member of the NSK Group. As a global leader in machinery protection and condition monitoring, B&K Vibro brings over 80 years of experience in vibration monitoring and advanced diagnostic solutions.

Their comprehensive systems deliver customized, seamless hardware and software solutions that monitor critical operational aspects of industrial machinery - from pumps and turbines to compressors, motors, and gearboxes. Through their integrated monitoring solutions, customers benefit from market-leading protection systems, diagnostics, and data analysis capabilities, ensuring total system visibility and comprehensive prognostic data for optimal machine performance and maintenance planning.

Benefits of Choosing NSK

- Preventive Maintenance

- Cost Optimization

- Extended Equipment Life

- Reduced Downtime

- Expert Support

- Global Service Network

Contact our experts to discover how NSK's condition monitoring solutions can optimize your operations.

Share