Troubleshooting Tools

Bearing & Linear Components Troubleshooting

NSK troubleshooting tools can help to identify and prevent future issues concerning:

- Contamination

- Misalignment

- Moment Load Issues

- Axial & Radial Load Issues

- Insufficient Lubrication

- Improper Handling

Troubleshooting (Bearing Doctor)

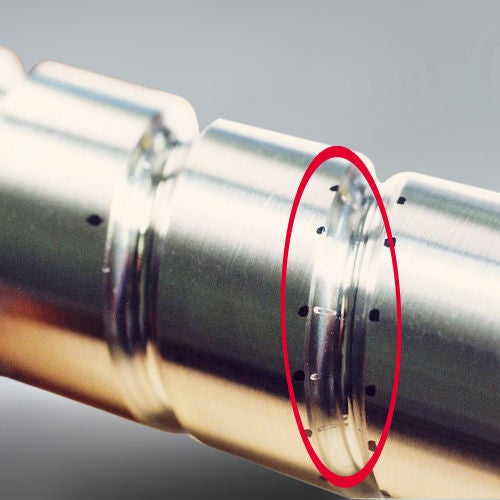

When a rolling bearing is damaged during machine operation, the entire machine or equipment may seize or malfunction. Since bearings that fail prematurely or unexpectedly cause trouble, it is important to be able to identify and predict failure beforehand, if possible, so that preventive measures can be adopted.

Troubleshooting (Bearing Doctor)

When damage or failures occur in a bearing, your entire operation can shut down. It is important to understand and be able to prevent these issues that may cause bearing damage.

Poor lubrication, improper handling, improper bearings selection or incorrect shaft and housing fits can be a few of the causes.

Taking into consideration the existing operation of the bearing before the failure, investigating the lubrication and mounting conditions while also carefully inspecting the damaged bearing itself will help you determine the cause of the damage in order to use countermeasures to prevent reoccurrence.

Learn more about our Troubleshooting:

Damage by Type

Damage by Location

Damage by Load / Contact Patterns

Troubleshooting - Linear Motion Components

Linear motion components such as Ball Screws and Linear Guides can have a naturally long service life with proper mounting and handling.

In the following troubleshooting selection for Linear Guides and Ball Screws, we show the most common types of damage, their possible causes and countermeasures so future issues are avoided.

Learn more about our Troubleshooting:

Linear Guides

Ball Screws

Share