Success Story

Industry: Food & Beverage

Application: Conveyor Belt

Cost Savings: $10,159

Introduction

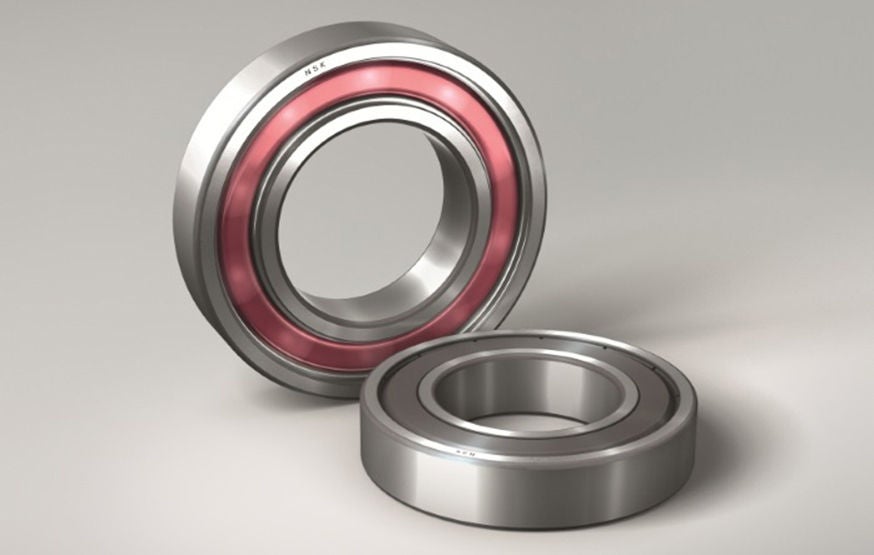

A vegetable-processing company was experiencing repeated ball bearing failures on their transport systems. NSK was asked to investigate the problem and offer a solution. It was determined that a large amount of water was entering the bearings and washing out valuable grease. NSK suggested the use of sealed, corrosion-resistant Molded-Oil Bearings. This solution allowed grease to remain in the bearings and increase bearing life.

- Conveyor Belt

- Molded-Oil Bearings

Key Facts

- Conveyor belt

- Vegetable processing

- Frequent bearings failures

- Service life of only 2 weeks

- Increased service life required

- NSK solution: Molded-Oil Bearings

- Result: Bearing lifetime increased from 2 weeks to over 9 months

Value Proposals

- The investigation carried out by NSK revealed that severe water ingress was causing problems (grease being washed out of the bearings)

- Use of corrosion-resistant Molded-Oil bearings

- Service life was significantly increased

- Cost saving realised

Product Features

- Molded-Oil provides continuous lubrication supply

- Stainless steel for corrosive environments

- Grease-free property with no oil refilling keeps operating environments clean

- Operating life more than twice as long as grease lubrication (in water or dust contaminated environments)

- Contact-seal type available in standard inventory for ball bearings

- Extended maintenance-free performance is acheived as Molded-Oil provides a continuous supply of lubricant.

- Available for high speed applications

- Available in ball bearing, spherical roller bearing and tapered roller bearings types

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Lubrication Costs: Lubrication cost | $6,955 | Lubrication Costs: No Lubrication costs | $0 | |

| Engineering Costs: Bearing mounting and dismounting | $3,204 | Engineering Costs: No costs for bearing mounting and dismounting | $0 | |

| Total Costs | $10,159 | $0 | ||

Reference:SS-E-1022

Share