Success Story

Industry: Food & Beverage

Application: Conveyor system

Cost Savings: $5,416

Introduction

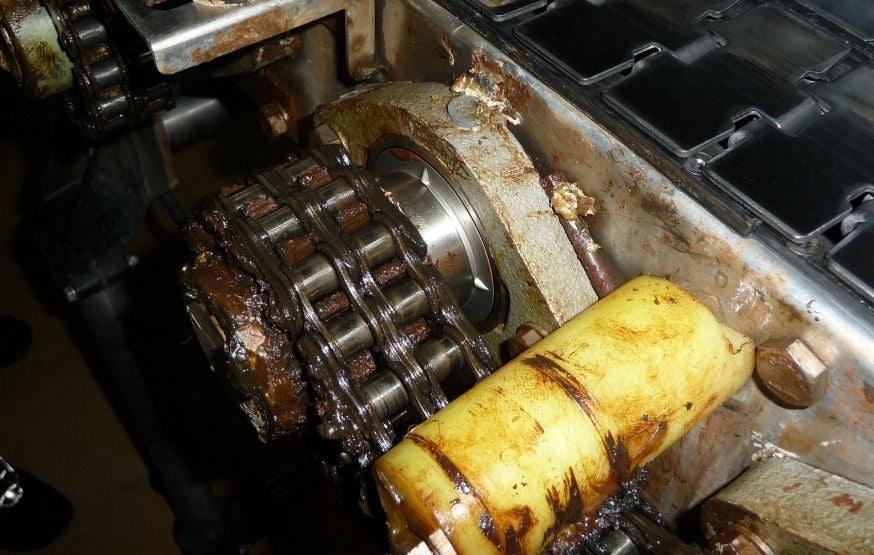

An international drink producer had repeated problems with mounted-unit inserts failing prematurely. Cleaning the equipment with water and chemicals was destroying the bearing seals and washing out grease. As a result, the mounted-unit inserts had to be replaced every 5 to 6 months and re-greased every 3 weeks. NSK was asked to find a solution in order to improve bearing service life.

- Conveyor drive

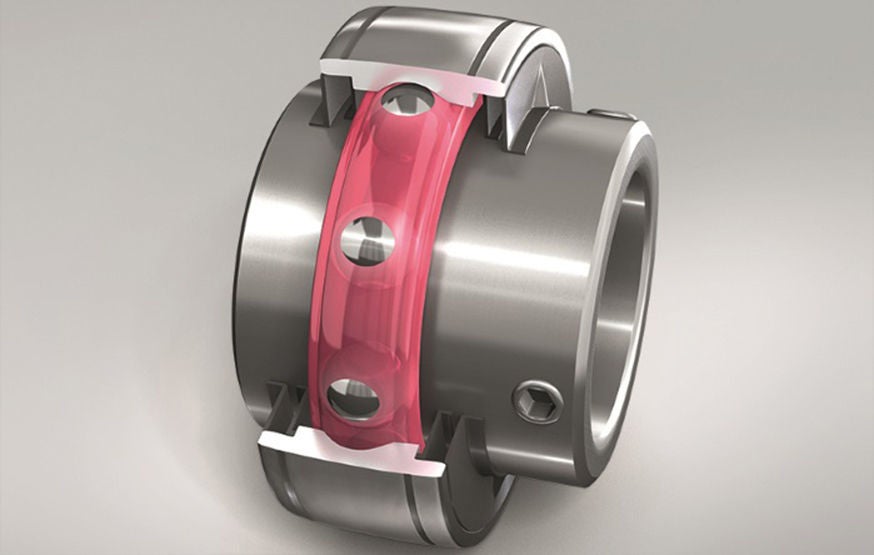

- Molded Oil mounted unit insert

Key Facts

- Drive/conveyor system (sorting plant)

- Premature failure of a competitor’s mounted-unit inserts

- Frequent relubrication

- Service life only 5 to 6 months

- NSK’s solution: replacing the mounted-unit inserts with NSK’s Molded Oil mounted-unit inserts

- No failures in the first year

- No additional greasing required

Value Proposals

- Failed bearing investigation showed seals were destroyed by the washing process which also depleted the grease

- Service lige doubled after samples were tested

- 100% reduction in servicing intervals (bearings previously lubricated 17 times a year)

- Ordering and fitting another 12 Molded Oil mounted-unit inserts

Product Features

- Molded-Oil inserts (with solid lubricant)

- Ideal for remote applications

- Martensitic stainless steel

- Integral Flinger seal and Nitrile rubber seals

- Bore size 20mm – 40mm

- Corrosion resistance

- Resistant to contamination increasing operating life

- No need for re-lubrication

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Lubrication Costs: Relubrication | $4,350 | Lubrication Costs: No relubrication | $0 | |

| Engineering Costs: Replacement & modification | $1,066 | Engineering Costs: No modification necessary | $0 | |

| Total Costs | $5,416 | $0 | ||

Reference:SS-E-1014

Share