Success Story

Industry: Power Transmission

Application: Gearboxes for Elevators

Cost Savings: $111,200

Introduction

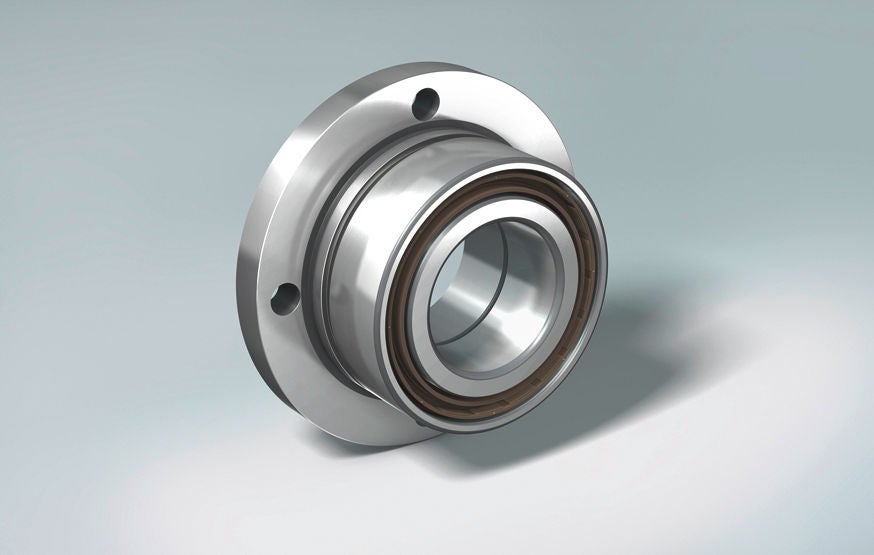

An international manufacturer of elevator gearboxes was experiencing unscheduled failures on its product during operation. NSK investigated the bearings within the application and found that a complex and difficult to assemble bearing arrangement was causing the inconsistent and inadequate performance. NSK suggested a much simpler solution featuring a fully integrated bearing assembly unit. This two-row flanged bearing unit reduced the number of components, was easier to assemble and offered superior performance compared to the original assembly.

- Elevator gearbox

- NSK flanged bearing unit

Key Facts

- Elevator gearbox manufacturer

- Irregular and unscheduled downtime

- Failures through complex and often incorrect assembly of bearings and components

- Need for greater performance and increased service life

- Testing of NSK flanged bearing units

- Approval of solution after successful testing

- Result: reduced downtime and maintenance work

Value Proposals

- NSK’s investigation showed that problems arose during installation of the bearings

- NSK training of employees in the installation and removal of bearings

- Machine design consultancy proposed NSK integrated flanged bearing unit

- Reduction of assembly and maintenance cost

- Increased bearing performance and reliability

- Annual cost savings of approx $111,200

Product Features

- 40° contact angle for high axial forces

- Compact design

- Specially developed seal material for gear oil

- Negative operating clearance

- Lifetime lubrication

- Housing sealed by O-Ring

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Bearing costs (incl. parts) Original Assembly |

$181,110 | Bearing Costs: Bearings Costs New NSK flanged bearings |

$243,777 | |

| Engineering Costs: Assembly costs (approx. 466h x $37.50/h) | $17,475 | Engineering Costs: Assembly costs (approx. 116h x $37.50/h) | $4,350 | |

| Engineering Costs: Maintenance Cost | $160, 742 | Engineering Costs: Maintenance Costs | $0 | |

| Total Costs | $359,327 | $248,127 | ||

Reference:SS-E-1001

Share