Success Story

Industry: Material Handling

Application: Optical Sorter

Cost Savings: $54,599

Introduction

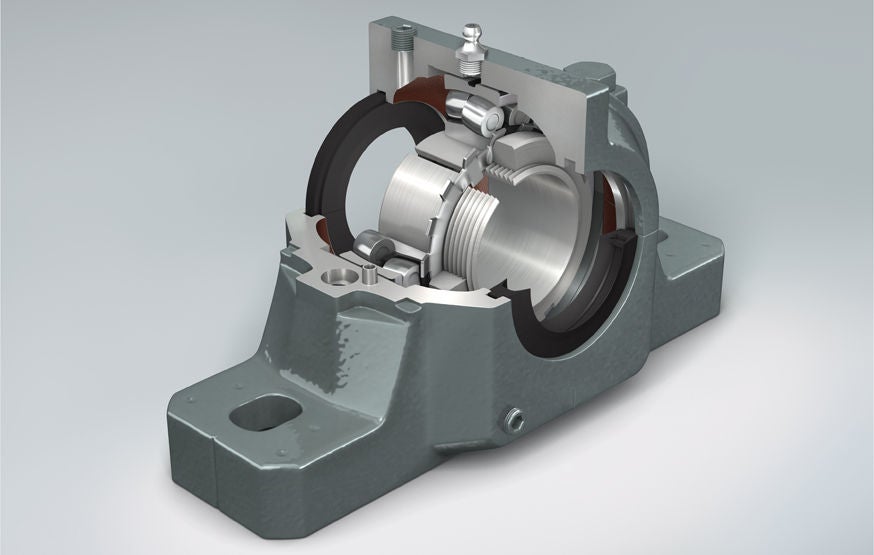

A recycler was experiencing regular failures of a mounted bearing unit on an optical sorting conveyor. In the three months after installation of the machine, a total of 5 bearing failures were recorded. An NSK application engineer examined the application and determined that vibration and lubrication issues were causing the bearing to fail prematurely. NSK recommended using SNN Plummer Blocks combined with NSKHPS Spherical Roller Bearings.

- Optical Sorter Conveyor

- NSK Plummer Block SNN series

Key Facts

- Optical sorting machine

- Mounted units failing prematurely

- Vibration causing grub screws to loosen and shaft to spin on bearing inner ring

- Heat generation caused by no lubrication escape path.

- NSK solution: SNN plummer blocks with NSKHPS Spherical Roller Bearings

- Elimination of bearing failures

- Significant reduction in downtime and maintenance costs

Value Proposals

- NSK Application Engineering performed an Application Review following a Failed Bearing Analysis

- It was determined that vibration had caused the grub screws to loosen, resulting in the shaft spinning in the bearing inner ring

- It was also determined that the type of mounted unit allowed for no grease escape path, which caused excessive grease build up resulting in high heat generation

- NSK recommended HPS Spherical Roller Bearings mounted on adapter sleeves in an SNN plummer block housing.

- The adapter sleeve locking method means that the bearing cannot come loose on the shaft even with vibration

- NSK SNN plummer blocks provided a grease escape hole as standard, allowing excessive grease build up is avoided

- No failures have been recorded since suggested recommendations were implemented

Product Features

- Equipped with 2 lubrication and 1 draining hole

- Solid base corners for locating pins

- Square shape and center marks

- Easy assembly and alignment with low maintenance costs

- High rigidity-minimizing deformation of the bearing seat

- Comprehensive range of sealing & arrangements to match all needs

- Excellent heat transfer

- Housing can be used with both double row self-aligning ball bearings or double row spherical roller bearings

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: 20 bearings annual | $8,998 | Bearing Costs: 4 bearings annual | $900 | |

| Costs of lost production: 10 breakdowns annual, 2 hours per breakdown, $2,250 per hour cost | $45,000 | Costs of lost production: No breakdowns | $0 | |

| Engineering Costs: Fitting and inspection | $3,000 | Engineering Costs: Initial fitting costs | $599 | |

| Training Costs: No Training | $0 | Training Costs: Training and install supervision | $900 | |

| Total Costs | $56,998 | $2,399 | ||

Reference:SS-E-2064

Share