Success Story

Industry: Pulp and Paper

Application: Paper Mill Combustive Air Unit

Cost Savings: $7,704

Introduction

An Italian paper company was experiencing reliability problems in a combustive air unit of a continuous paper machine. The bearings within the application were only lasting 4 months on average. In some cases, they broke down prematurely causing unplanned maintenance. The customer requested an NSK technical proposal in order to increase bearings life. NSK engineers analyzed the application and found that the high temperature was causing bearing failure. NSK proposed a high temperature specification bearing (heat treatment, seals and lubrication grease). Since implementation the bearings are still running after 12 months. The solution reduced maintenance requirements and in addition, re-lubrication operations are no longer necessary.

- Paper Mill Combustive Air Unit

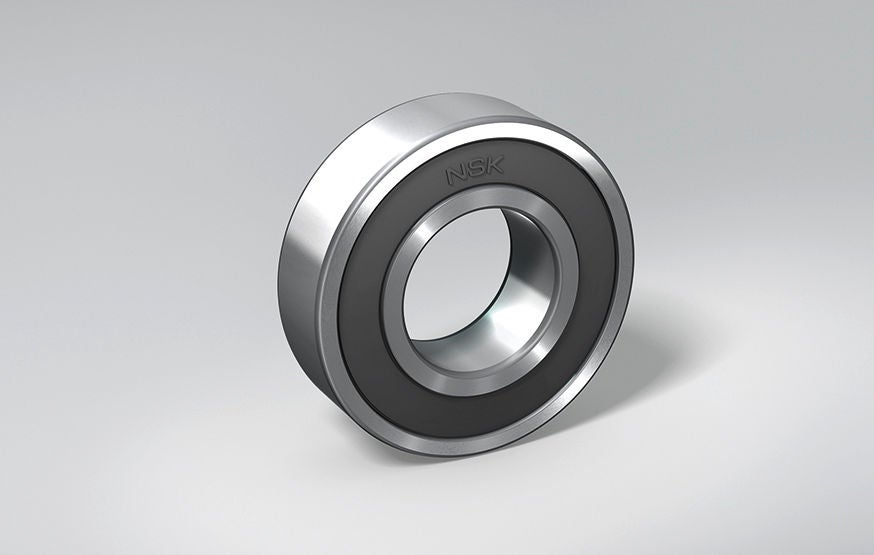

- High Temperature Sealed DGBB

Key Facts

- Combustive air unit

- Bearing failures due to high temperature

- NSK solution: Deep Groove Ball Bearing for high temperatures

- 3x's increase in bearing life

- Eliminated unexpected downtime

Value Proposals

- NSK performed Application Review

- Failed Bearing Analysis showed bearing failures due to high operating temperature

- NSK proposed Deep Groove Ball Bearings with high temperature features resulting in 3x's longer bearing life

- Eliminated downtime

Product Features

- Steel Cage

- Heat treated rings

- C3 Internal clearance

- High temperature grease

- Viton®* Seals

- "E" class (noise level)

- High performance in contaminated environment

- Temperature stability: up to 150°C

- Longer bearing life through superior seal performance

- Reduced noise level "E" class for electrical applications

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Bearing replacements | $312 | Bearing Costs: Bearing replacements | $122 | |

| Engineering Costs: Maintenance time 3 hours/failure Costs $27/h x 3 people |

$972 | Engineering Costs: Maintenance time 3 hours/failure Costs x $27/h x 3 people |

$243 | |

| Costs of lost production: Downtime x 3 hours x $748/h 4 replacements |

$8,976 | Costs of lost production: Downtime x 3 hours x $748/h 1 replacement |

$2,245 | |

| Lubrication Costs: 24 operations x 5 min x $27/h | $54 | Lubrication Costs: Lubrication no longer necessary | $0 | |

| Total Costs | $10,314 | $2,610 | ||

Reference:SS-E-4005

Share