Success Story

Industry: Food & Beverage

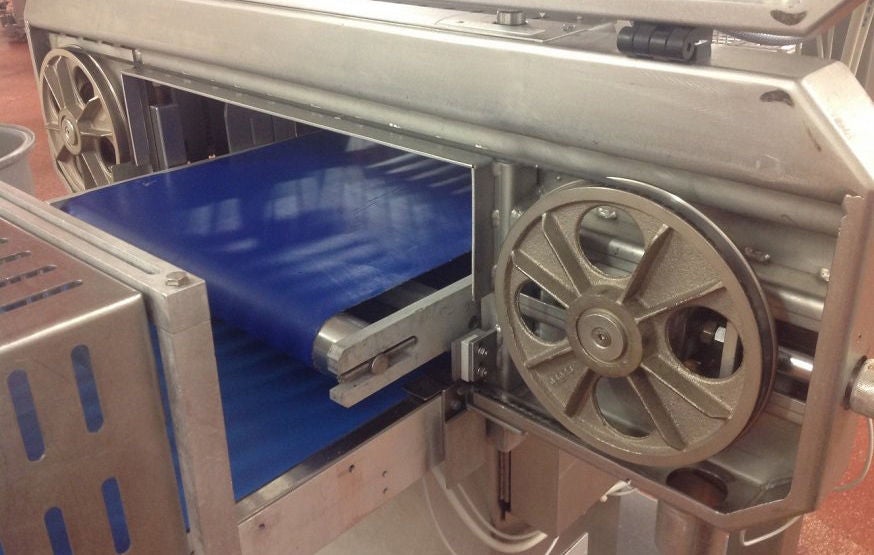

Application: Cutters - Cream Line

Cost Savings: $9,942

Introduction

A customer was experiencing repeated bearing failures on their blade saw pulleys within the cake cutting units. Bearings were failing every 4-6 weeks with approximately 20 bearing sets beign changed annually. Investigation by NSK showed the failures were caused by the ingress of water and hard particulates. NSK recommended replacing the standard bearings with NSK Molded-Oil units. With tested bearings life lasted up to 26 weeks, this improved productivity and offered cost saving in replacement and maintenance time.

- Cake Cutter Blade Saw

- NSK Molded-Oil Bearings

Key Facts

- Frequent bearing failure- approximately 40 bearings being replaced annually

- High number of man hours needed to replace failed bearings

- High machine down time leading to costly loss of production

- NSK Solution: Molded-Oil Ball Bearings

- Productivity improvement

Value Proposals

- NSK Application Review determined the bearings had failed due to the absence of lubrication and ingress of water and hard particulates

- Having completed the review NSK recommended the use of Molded-Oil ball bearings

- A trial using Molded-Oil Ball Bearings was implemented

- The trial resulted in a substantial increase in bearing life and reduction of machine down time

Product Features

- Molded-Oil provides continuous supply of lubrication oil

- Grease-free property with no oil refilling keeps operating environments clean

- Operating life more than twice as long as grease lubrication, in water or dustcontaminated environments

- Contact-seal type available in standard inventory for ball bearings

- Achieves extended maintenance-free performance as Molded-Oil provides a continuous supply of lubricant; available for high speed applications

- Available in Ball Bearing, Spherical Roller Bearing and Tapered Roller Bearings types

- Stainless steel for corrosive environments

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Bearing replacement: | $549 | Bearing Costs: Bearing replacement: Molded-Oil | $567 | |

| Engineering Costs: Maintenance: | $1,080 | Engineering Costs: Maintenance: | $0 | |

| Engineering Costs: Lost man hours: | $5,389 | Engineering Costs: Lost man hours: none | $0 | |

| Engineering Costs: Additional replacement costs: Blade & shaft | $3,541 | Engineering Costs: Additional replacement costs: Blade & shaft | $50 | |

| Total Costs | $10,559 | $617 | ||

Reference:SS-E-2073

Share