Linear Motion Product Selection Tools

Selection Tools for Precision Machine Components (Linear Products). Find the right product for your application with our selection tools for ball screws, NSK Linear Guides, Monocarriers, and Megatorque Motors (direct drive motors).

NSK Linear Motion Products; Selection Tools

Direct Drive Motor Selection Tool

Please check the following conditions when you select and examine NSK Ball Screws.

1. In case of oscillating motion

If the rolling elements do not rotate all the way, but only halfway, and if this minute stroke is repeated, lubricant disappears from the contact surface of rolling elements and raceways, and metallic parts directly make contact each other. This generates "fretting," a premature wear. Fretting cannot be entirely prevented, but it can be mitigated.

- Grease which prevents fretting is recommended.

- Even when standard grease is used, the life can be markedly prolonged by adding a long stroke once every several thousand cycles. (The rotation speed would be more than twice the effective turns of balls. For example, be more than 5 rotation in the case that the effective turns of balls is 2.5.)

2. When an extraordinary heavy load is applied during stroke

When an extraordinary heavy load is applied during stroke, the actual life could be extraordinarily shorter than the calculated life. In such a case, the contact pressure to the balls/rollers and the rolling contact surface is extraordinarily high.

- Please examine the life in view of the contact pressure.

Please check the following conditions when you select and examine NSK Linear Guides.

1. In case of oscillating motion

If the rolling elements do not rotate all the way, but only halfway, and if this minute stroke is repeated, lubricant disappears from the contact surface of rolling elements and raceways, and metallic parts directly make contact each other. This generates "fretting," a premature wear. Fretting cannot be entirely prevented, but it can be mitigated.

- Grease which prevents fretting is recommended.

- Even when standard grease is used, the life can be markedly prolonged by adding a long stroke (long more than the slide length) once every several thousand cycles.

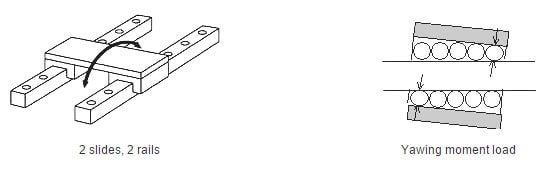

2. When applying pitching or yawing moment

The load applied to the rolling element rows inside the slide is inconsistent if a pitching or yawing moment load is applied. Heavy load occur on the rolling elements on each end of the row.

- A heavy load lubricant grease or oil are recommended.

- Please use one size larger model of linear guide to reduce the load per rolling element.

- Applying super-high-load type should also be examined.

3. When an extraordinary heavy load is applied during stroke

When an extraordinary heavy load is applied during stroke, the actual life could be extraordinarily shorter than the calculated life. In such a case, the contact pressure to the balls/rollers and the rolling contact surface is extraordinarily high.

- Please examine the life in view of the contact pressure.

4. When the calculated life is extraordinarily short (Less than 3000 km in calculated life)

In such case, the contact pressure to the rolling elements and the rolling contact surface is extraordinarily high. If the linear guides are operated under such state continually, the life is significantly affected by the loss of lubrication and the presence of dust, and thus the actual life becomes shorter than calculated.

- It is necessary to reconsider the arrangement of linear guides, the number of slide, and the type of model in order to reduce the load to the slides.

5. Upside-down installment (ex. on the ceiling)

When hanging upside-down (e.g. the rail is installed upside-down on the ceiling in which the slide faces downward), should the end cap be damaged, causing the balls or rollers to fall out, the slide may be detached from the rail and fall.

- Please take measures including installing a safety device.

Share