Industry Experts

Working Side-by-Side for Customer Success

When NSK is on-site, we’re there to understand our customers’ challenges and identify problems leading to frequent bearing replacement, breakdowns caused by poor specification, high energy costs from inefficient product selection and lost production because of downtime. We apply these learnings, our knowledge and experience to collaborate with our customers to implement improvements that deliver measurable value in terms of performance, productivity and maintenance cost efficiency.

Maintenance Services

NSK’s industry experts can provide assistance at every stage of your bearing’s life, from installation to regular inspection and maintenance to reconditioning. We fully understand the performance factors for every application, the failure modes that can impact bearing performance, and the countermeasures that will deliver the long life and smooth running your operation needs.

Our range of services and support includes:

- Process Mapping

- Inventory / Critical Spares Management

- Inspection & Diagnostics

- Bearing Installation and Removal

- Scheduled Maintenance Programs

- Best Maintenance Practice Training

With NSK on-site support, our customers take a critical step forward in realizing improvements in equipment, productivity, people and financial performance.

NSK Web Tools and Apps

Bearing Selection

NSK Bearing Catalog

Our interactive catalog helps you to select the correct bearings that best meet the dimension and operating performance requirements of your application and equipment.

NSK Bearing Calculation Tools

Calculate bearing life, recommended fits and clearances, frequencies, lubrication viscosities and relubrication intervals, frictional moment and speeds with NSK NAVI-FOCUS.

NSK Bearing CAD Models

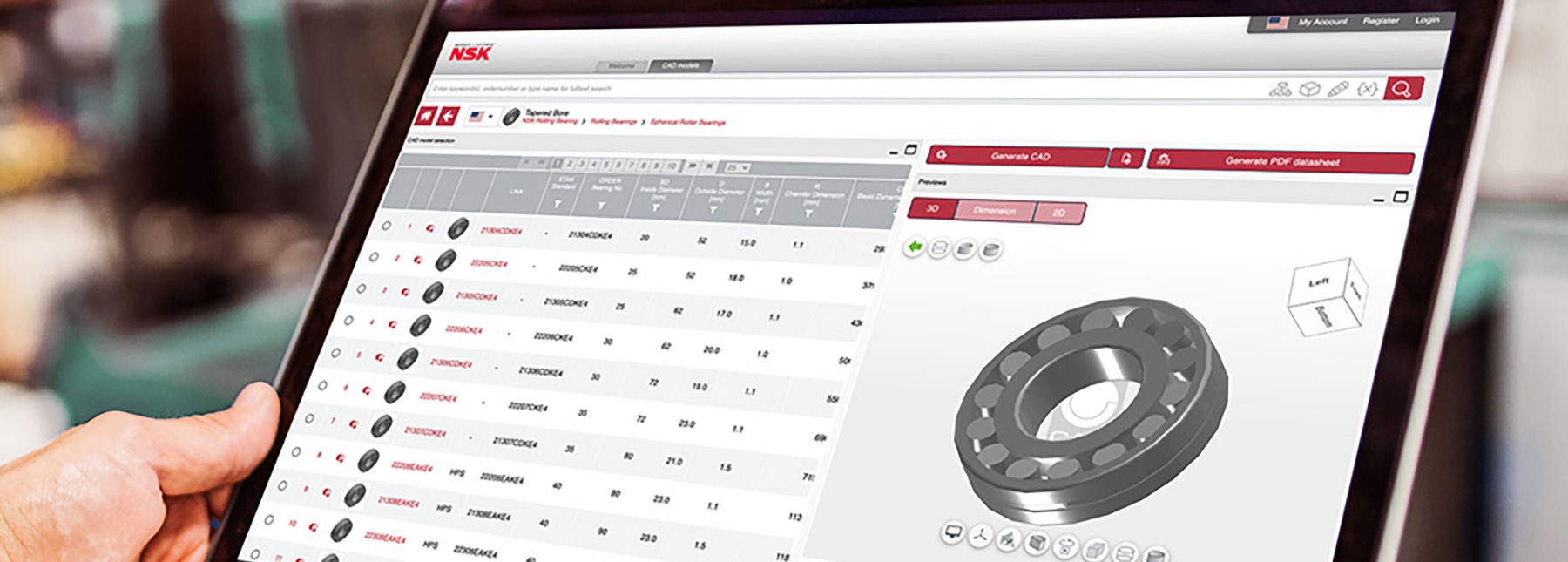

Select your bearing type, validate suitability of dimensional and performance criteria, and download the CAD model to incorporate into your machine and equipment design.

Bearing Performance

NSK Bearing Doctor

Engage and interact to diagnose bearing damage and possible causes while discovering handling and maintenance practices to avoid bearing failure and unplanned downtime.

AIP Cost-Savings Calculator

Quantifiable improvement is derived from reduced bearing usage, maintenance costs and lost production. Calculate the total attainable cost savings from an NSK recommended solution.

AIP Cost-Benefit Calculator

Improvement may require short-term investment to achieve long-term efficiency gains. Calculate the break-even point where an NSK solution begins to yield cost benefits.

Share