Linear Guides

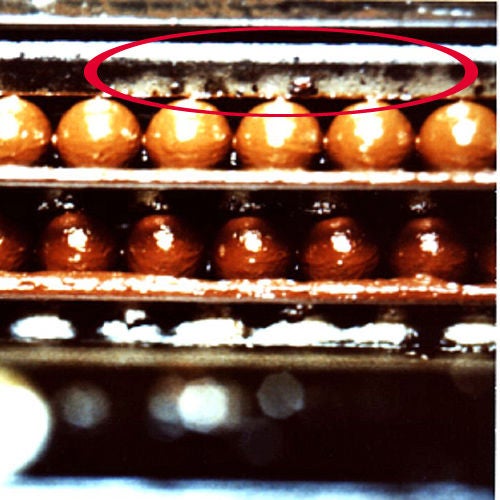

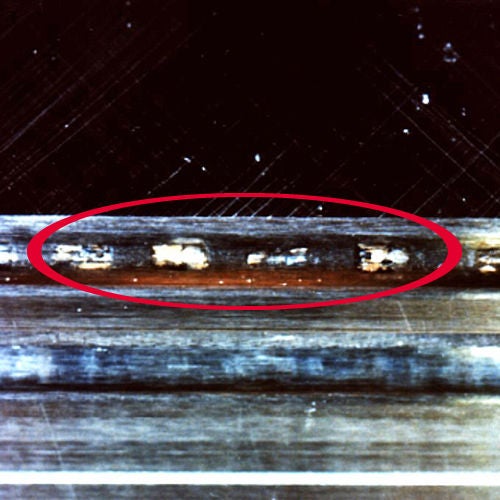

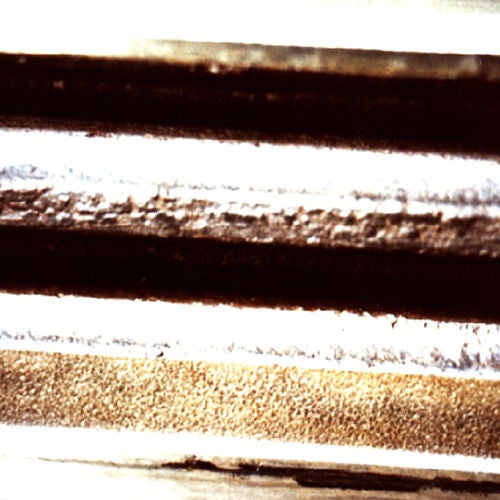

When Linear Guides reach their rolling fatigue life, particles start to separate from the surface of the raceways and balls resulting in “flaking”.

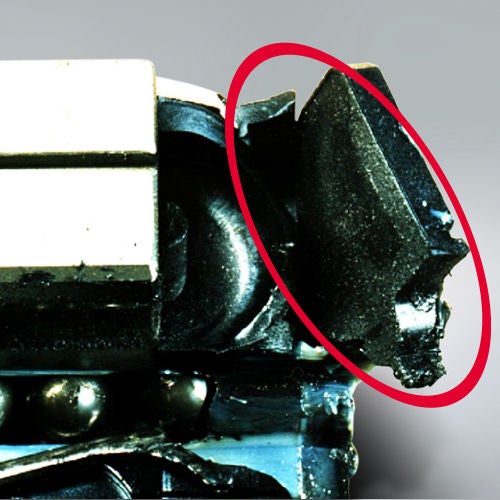

In some cases, premature flaking or abnormal damage may lead to machine failure. Causes includes improper handling, excessive misalignment, insufficient lubrication or contamination.

Often the cause can be a combination of these facors. It's possible to prevent these problems from reoccuring by making a complete investigation into a prematurely failed product. This includes examining handling procedures, installation processes, maintenance history and any operational environment history, all of which can be used to diagnos the cause of faliure.

Click a photo to visit page

Share