Businesses

Supporting the evolution of industry, from automobiles and home appliances, to industrial machinery, railways, and aerospace.

NSK’s broad lineup of products and services, including bearings and ball screws, has underpinned the development of countless industries for over 100 years. With our technical expertise cultivated over a century, we provide our customers with the right solution to meet their specific application requirements.

NSK's Businesses

Supporting Next-Gen Vehicles

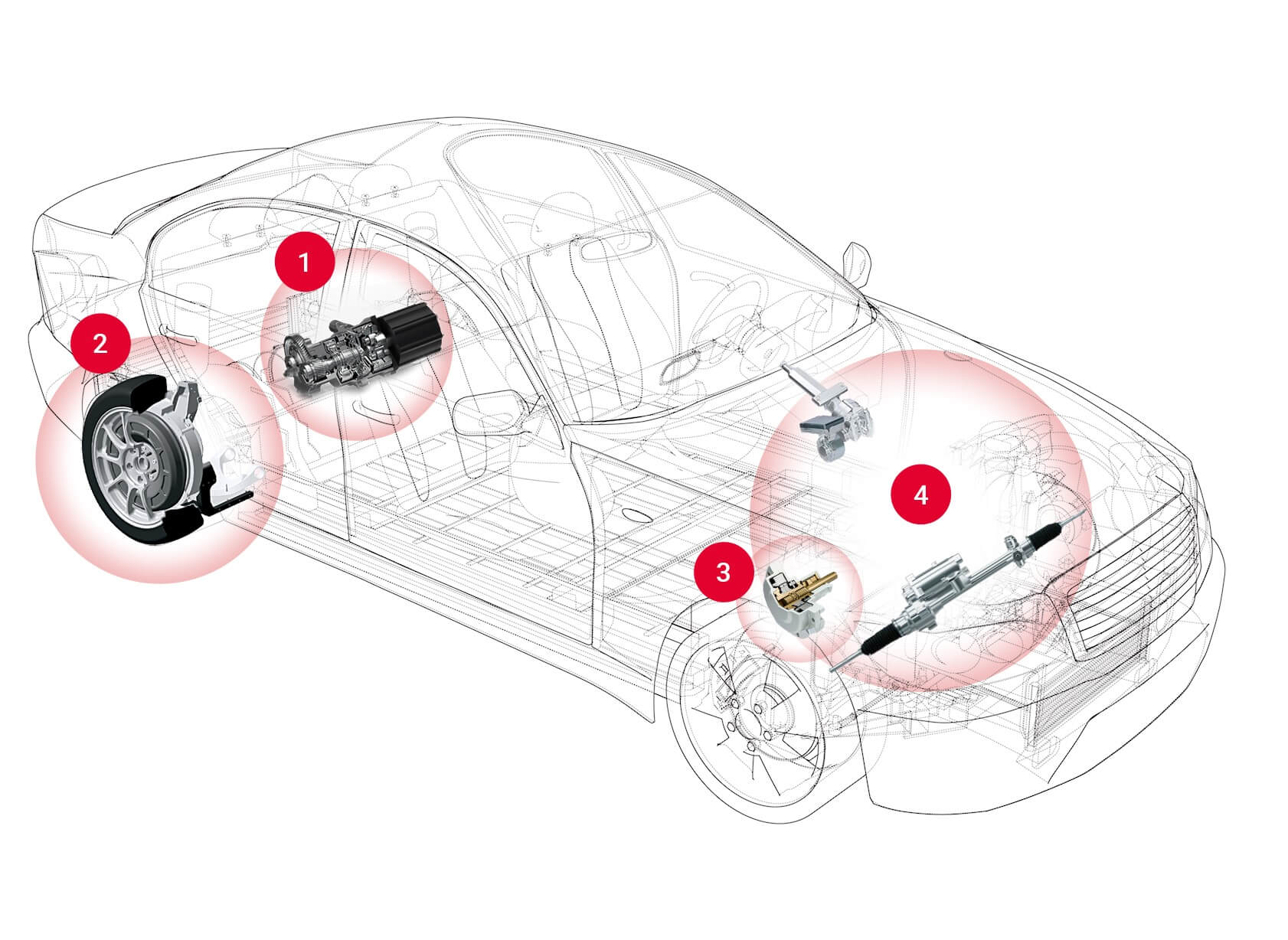

In addition to bearings, we offer a range of value-added solutions to support the three primary functions of a vehicle: driving, steering, and stopping, as well as technologies and solutions tailored to CASE (Connected, Autonomous, Sharing, and Electrification) and the diversification in mobility technologies.

-

1Seamless 2-Speed e-Axle Concept

This proprietary NSK technology combines a traction drive that further increases the rotational speed of the EV motor with a torque sensor that enables smooth gear shifting. The concept design helps solve key EV-related issues by extending vehicle range and enhancing driving performance, while contributing to ride comfort and drivetrain size/weight reduction.

-

2In-wheel Motor with Wireless Charging Unit

A research group comprised of NSK, the University of Tokyo, and other companies succeeded in developing and testing a third-generation wireless in-wheel motor (W-IWM) capable of charging from coils embedded in the road while in motion. This system makes electric vehicles much more convenient by enabling them to be charged while the vehicle is in motion.

-

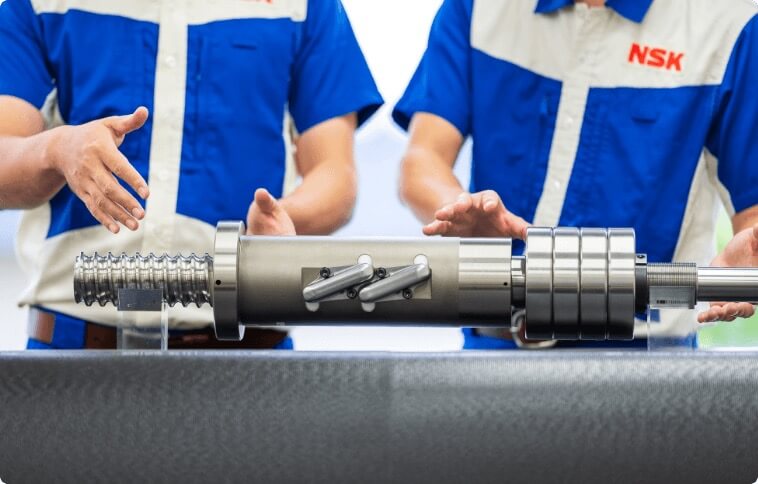

3Ball Screw Actuator for Electric-Hydraulic Brakes

A low-friction ball screw improves brake response by enabling reliable high-speed operation and precise control. Integrated bearings and peripheral parts achieve compact size and low weight. The increased safety delivered by this product will contribute to the development of electric vehicles (EVs) and hybrid electric vehicles (HEVs), as well as to autonomous driving.

-

4Steer-by-Wire Force Feedback Actuators (FFA) & Steer-by-Wire Road Wheel Actuators (RWA)

Steer-by-Wire systems eliminate the physical connection between the steering wheel and the tires, opening up new possibilities for vehicle design layouts, as well as for the autonomous driving systems of the future. NSK is currently developing hardware and software for safe and secure steer-by-wire systems, including force feedback actuators (FFA) and road wheel actuators (RWA).

Driving the Future of Industry

With the keywords of electrification, automation, digitalization, and environment, NSK is working together with our customers to leverage our advanced technologies to create new value.

-

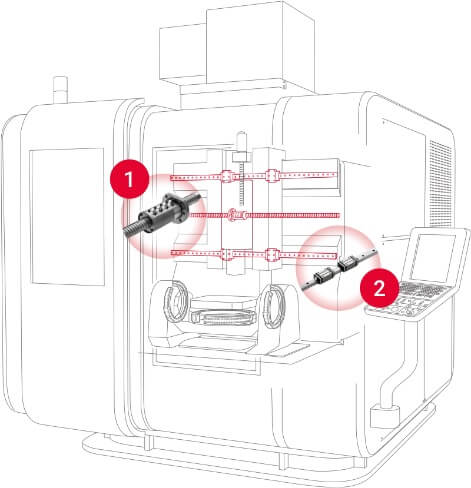

1Next-Generation High-Durability Precision Ball Screws

NSK's ball screws, which make high-precision positioning possible, underpin high-quality manufacturing worldwide. Using advanced simulation technology, we have deciphered the frictional characteristics of ball screws to achieve high-precision motion and reduce dynamic frictional torque. We will continue making further advances in high-precision machining and energy conservation, both technologies that will be increasingly required in the future.

-

2NSK Linear Guides™

NSK Linear Guides™ are used in a wide range of applications, mainly in various types of production equipment such as semiconductor and LCD manufacturing equipment, automotive manufacturing equipment, conveyor robots, and machine tools. We have achieved longer service life by designing rolling surface geometries that optimize the distribution of contact pressure between the rolling elements (balls and rollers) and the raceway surface, thereby improving reliability. Going forward, NSK Linear Guides™ will contribute to further automation, such as in smart factories.

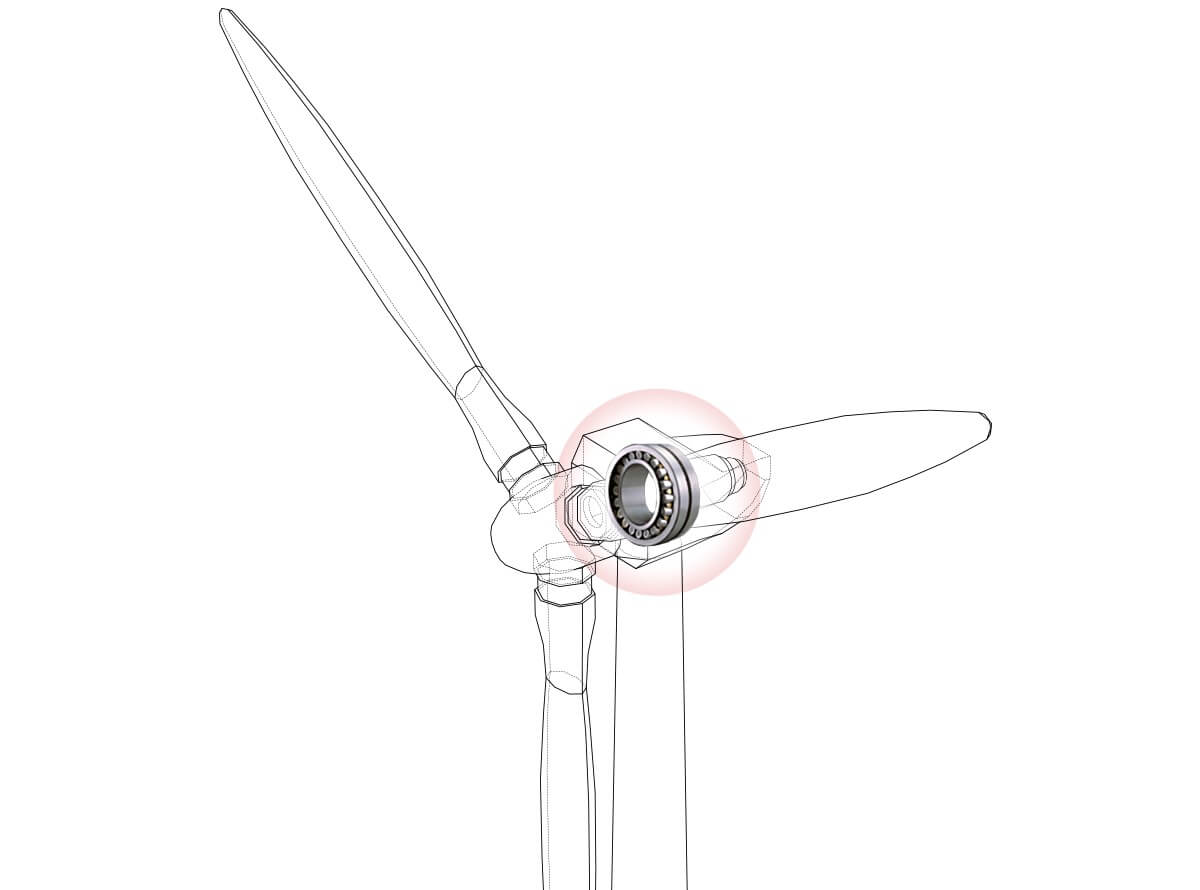

Large cylindrical roller bearings (for gearboxes)

Miniature Precision Ball Bearings for Dental Drills

Creating a Sustainable Society

At NSK, we are working to leverage our technological strengths to develop new technologies and products, and to create and propose new value to society.

Bioplastic Bearing Cages

-

NSK developed the world's first bioplastic cage for rolling bearings

-

Plant-derived material reduces lifecycle CO2 emissions by 90%

-

Achieved 66% faster development time with new NSK dual-perspective (digital twin) development approach.

Heat resistance has proved an issue with plastics made from renewable biological (primarily plant) resources.NSK's bioplastic bearing cages can be used in high-temperature environments up to the 120°C range, helping reduce CO2 emissions from raw materials and contributing to the realization of carbon neutrality.

Transport Robot for Medical Institutions

-

Enables safe transport of heavy loads without physical strain.

-

Helping transform work styles in the medical field

NSK has lent its technological capabilities to a project by Japan's Kanagawa Prefecture aimed at preventing the spread of COVID-19 and reducing the burden on healthcare professionals by using robots to reduce person-to-person contact. We developed a robot that can help to move stretchers and beds, featuring a motor drive, smooth acceleration and deceleration, and the ability to turn in tight spaces. We invite medical professionals to test using a stretcher fitted with the robot, and based on the feedback received, our engineers are continuing to make improvements to the design.

Motor Hub with Variable Pitch Mechanism for Large Drones

-

NSK's advanced technology for motors contributes to improved aircraft stability and cruising range

-

Future application in helping to solve societal challenges such as urban traffic congestion

Anticipation is growing for the commercialization of "flying cars" as an alternative means of transportation to replace conventional automobiles. NSK has developed a motor hub unit for drones that allows precise adjustment of the blades (wings) and pitch angle. This enables highly responsive thrust (lift) while optimizing energy efficiency, contributing to improved aircraft stability and cruising range.