NSK Vision 2026

NSK Vision 2026

In 2016, NSK celebrated its 100th anniversary. NSK Vision 2026 was established the same year

to convey our aspirations for the next 10 years, as the first step on our journey through

another century. At the center of Vision 2026, the message “Setting the Future in Motion,”

represents our commitment to bringing safety, reliability, and comfort to people's

lives—enriching lifestyles and building a brighter future through our products and services

across our automotive business, industrial machinery business, and a wide range of other

business fields.

Have what it takes to build the future? Join the team that moves the world.

NSK Corporate Philosophy

NSK contributes to a safer, smoother society and helps protect the global environment

through its innovative technology integrating Motion & Control™. As a truly

international enterprise, we are working across national boundaries to improve

relationships between people throughout the world.

Our Business Strengths

Our Business Strengths

Diversification

Ever since NSK became the first company in Japan to produce bearings in 1916, we

have continued a strong tradition of R&D pursuing the leading edge of

technology. The result? Today, we hold a leading market share both in Japan and

globally— not only for bearings, but also ball screws, linear guides, and a

range of other products. We offer a broad range of advanced products to support

manufacturing needs, and this diversified business provides a stable management

portfolio. With a firm focus on the future, we are also leveraging NSK's

technological strengths to develop new technologies and products that can

deliver new value and provide solutions for a sustainable society.

Source: Nikkei Business Daily

Company Culture

In a world where component suppliers are often tied to a single large customer,

NSK has always maintained its independence. We set our own business strategy to

build on inter-field synergies and create new products and services unlike

anything before, adding value for our customers around the world across an

astonishing range of industries—from heavy machinery such as aircraft and

machine tools to everyday items such as computers and smartphones. How does the

NSK brand achieve its global reputation for high quality and reliability?

Through our world-leading technology, elite talent, and a proactive company

culture rooted in a “Change and Go Beyond” spirit. Going forward, we will

maintain our position as a needed and trusted company by broadening our horizons

and finding new and innovative ways to contribute to society through our

technology.

Global Strategy

NSK was one of the first Japanese manufacturing companies to expand its business

outside Japan. After launching overseas exports in 1948, we began overseas

production in countries such as Brazil, the U.S., and the U.K. in the 1970s,

laying the foundation for our global business by manufacturing products locally.

From the 1980s onward, we expanded our production lineup as our Japanese

customers, primarily in the electric and automobile industries, expanded their

global operations, and in the 1990s, we established production sites in

countries including China, Indonesia, Thailand, and India against the backdrop

of economic growth in emerging economies. We also operate technology centers

around the world, including the U.S., Germany, Thailand, and China, to

dynamically respond to developments in the global business environment and

flexibly serve our customers. Our global network and local proximity to key

industries is a critical factor to our success.

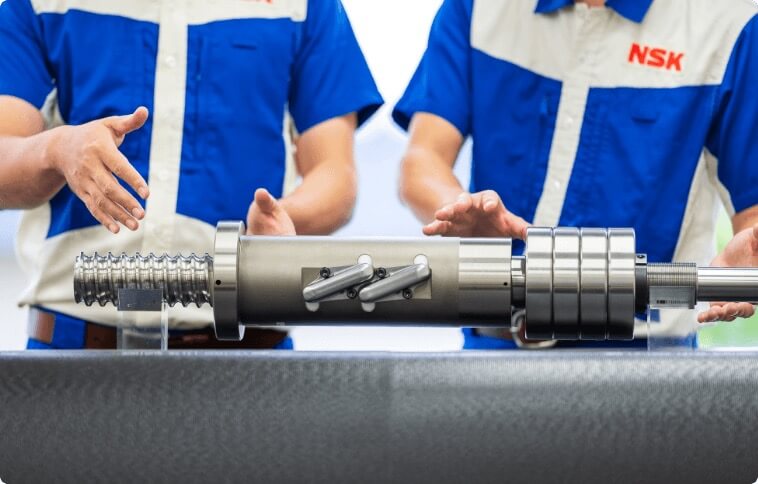

Four Core Technologies

Plus One

Four Core Technologies

Plus One

Plus One

NSK has relentlessly pursued innovative technologies and focused on improving quality in

order to contribute to a safer, smoother society and to protect the global environment,

in line with its corporate philosophy. The foundation that underpins those technologies

consists of tribology, materials, numerical simulation and mechatronics, which are NSK’s

Four Core Technologies.

Then there is manufacturing engineering, another important technology and strength of

NSK that gives shape to our Core Technologies.

The technologies and products that have been created based on our Four Core

Technologies, with the “plus One” of manufacturing engineering, are contributing both to

the development of industry across the world and to people’s abundant lifestyles.

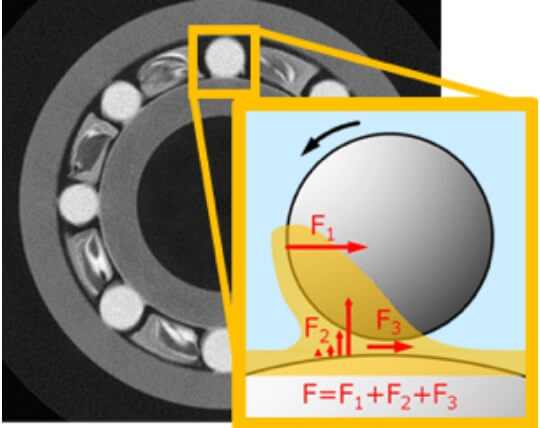

Tribology

Studying, Clarifying and Controlling Friction

Tribology is the study of friction and wear of contact surfaces in relative

motion, such as rotating parts that endure enormous forces with a thin oil

film. Severe operating conditions are mitigated through lubrication and

surface treatments developed by NSK, resulting in superior performance for

applications requiring low friction, high-speed rotation, quiet operation,

or enhanced durability.

Materials

Unrelenting Pursuit of Performance Durability and Reliability

Materials research and development affects nearly every aspect of product

performance. Through careful selection of material composition, heat

treatment, and ceramic materials, NSK enables optimization of application

performance. This may result from improvements in function, endurance, or

reliability, or through advancements in cost-effectiveness or production

efficiency.

Numerical Simulation

Simulated Recreation in Cyberspace to Predict Performance

In the past, accuracy and reliability in product development were achieved

with experience-based design and longer testing periods. NSK’s simulation

technology allows virtual validation to accelerate design and production.

Extreme conditions or innovative designs that defy previous expectations can

also be evaluated and analyzed.

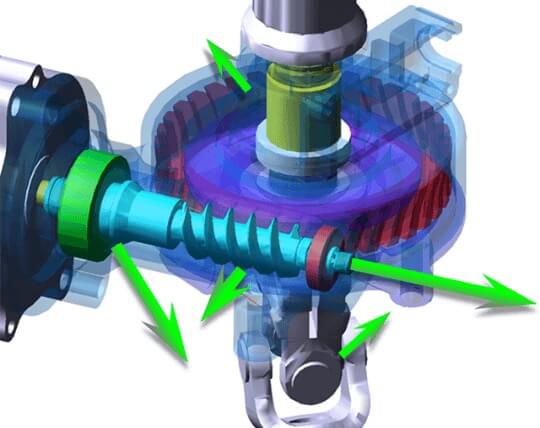

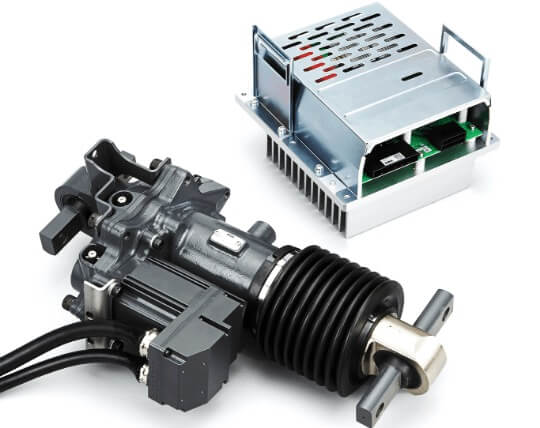

Mechatronics

Technology Supports People for a Convenient, Safe and Comfortable Future

Mechatronics integrates machine elements technology with control technology.

By combining bearings, ball screws and linear guides, together with motors,

sensors and computers, greater mechanical functionality is elicited with

computer control. This technology applies new functions and performance to a

range of industrial machinery, such as for automobiles and bio-medicine. It

also contributes to greater reliability, as well as to convenience and

safety in daily life.

Manufacturing Engineering

Giving Shape to Four Core Technologies

Contributing to the environment and heightening safety and security through

our Four Core Technologies requires something to breathe life into these

technologies. In addition, it is essential to consistently produce with high

quality. NSK tackles these issues by applying AI to its equipment, utilizing

IoT, and optimizing its overall production framework while it works to

realize the creation of smart factories that economize on space, save on

energy, and reduce manpower requirements.

Company Info

Company Info

- Company Name

- NSK Ltd.

- Established

- November 8, 1916

- Capital

- 67.2 billion Japanese Yen (as of March 31, 2022)

- Head Office

-

Nissei Bldg., 1-6-3 Ohsaki, Shinagawa-Ku, Tokyo, 141-8560, Japan

Google Maps - Phone

- +81-3-3779-7111 (Japan headquarters)*Please contact your regional headquarters

- Representative

- Akitoshi Ichii, President & CEO

- Number of Employees

- 30,577 (as of March 31, 2022)

- Annual Net Sales

- 865.2 billion Japanese Yen (Year ended March 31, 2022)

- Guide Map

- NSK Head Office Route Map / Area Map

- Main Businesses

-

Industrial: Bearings, ball screws, precision machinery and parts

Automotive: Bearings, steering systems, automatic transmission products