NSK Ltd.

Corporate Communications Department

NSK Announces MT-Click!Speedy™, a New Bearing Analysis Tool for Machine Tool Main Spindle Bearings Coming This Year

Easier and quicker analysis for faster NSK bearing selection

- NSK will release a new analysis tool called MT-Click!Speedy before the end of this year, allowing customers to easily and quickly perform analysis for bearings used in machine tool main spindles based on NSK’s know-how.

- Previously, NSK conducted analysis and provided the results to customers. However, with this new tool, customers can now perform analysis themselves, allowing them to quickly reflect changes in their bearing operating environments and conditions and then output analysis results.

- The new tool enables shorter lead time for obtaining analysis results, which in turn means less time needed for customers to select bearings.

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) announced today that it has developed MT-Click!Speedy*1, a new analysis tool for machine tool main spindle bearings.

With this analysis tool, customers can easily and quickly perform analysis based on NSK’s know-how for angular contact ball bearings and cylindrical roller bearings, which are typically used in the main spindles of machine tools.

Previously, analysis of machine tool main spindle bearings was conducted by NSK upon request from their customers. With the public release of this tool, customers can quickly perform analysis themselves based on their bearing operating environment and conditions. (For example, analysis results can be easily output as a PDF report and sent via email.) This means shorter time required for customers to select bearings thereby helping to improve product development speed.

NSK will exhibit this analysis tool at the 32nd Japan International Machine Tool Fair (JIMTOF 2024) to be held from November 5 to November 10, 2024. Based on feedback to be received at the fair, NSK will release the tool on its website’s engineering tool page both domestically and internationally by the end of the year.

*1 MT = Machine Tool

1. Development Background

The machine tool manufacturing industry is facing various challenges, including increasing demand and the emergence of new manufacturers in emerging economies, changing needs due to the diversification of end-user lifestyles, and intensifying global competition. In such an environment, machine tool manufacturers are required to have the flexibility to respond to rapid changes in demand and needs, as well as the ability to develop products quickly while maintaining technological superiority.

Bearings are important mechanical components in the design process of machine tools, and shortening the time required to select bearings is essential for shortening development lead times. Bearing selection is based on the customer’s evaluation of the bearing analysis results, which were previously provided by NSK. Therefore, the machine tool industry has been demanding a tool that allows customers to easily and quickly analyze NSK bearings themselves to shorten the lead time from analysis request to receipt of analysis results.

2. Analysis Tool Features

1) Customers can perform analysis based on NSK’s know-how

With the new analysis tool, customers can perform analysis themselves based on NSK’s long-standing know-how, according to the bearing operating environment and conditions.

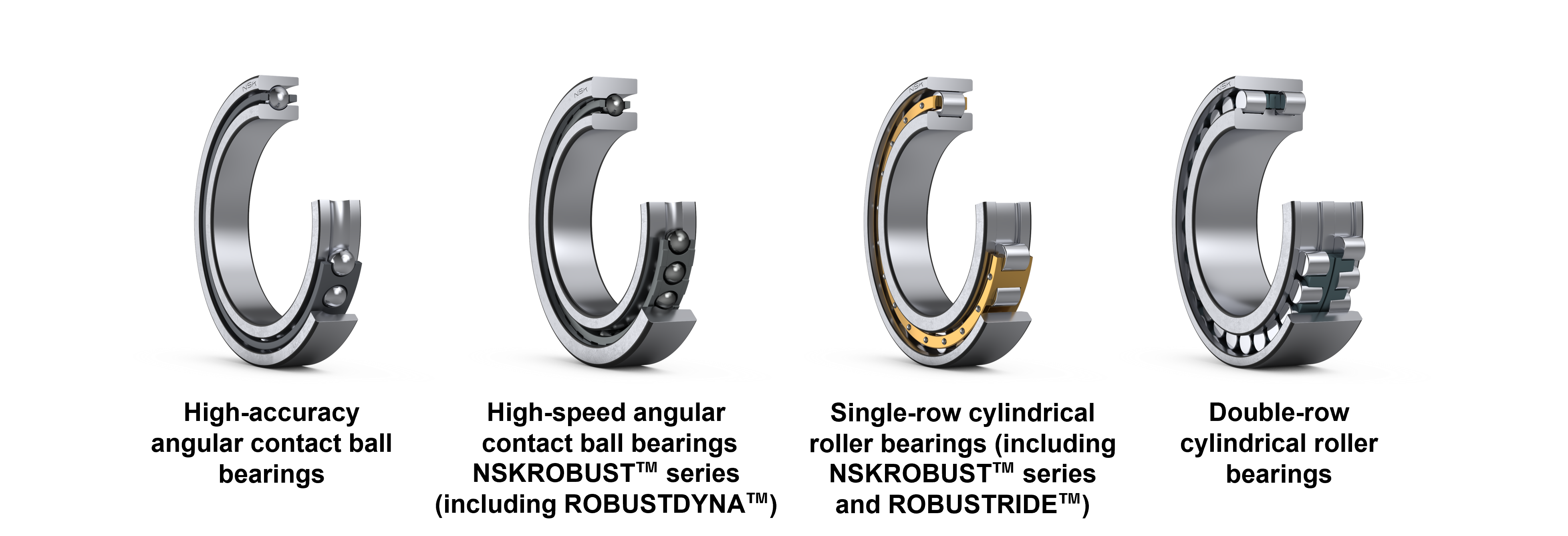

・ Supported bearings: NSK bearings used in machine tools as shown below.*2

・ Analysis content: Bearing installation characteristics (e.g., preload, clearance, rigidity), operating characteristics (e.g., rigidity, rolling contact fatigue life, heat generation), etc.

Supported bearings

*2 Excluding some products

2) Easy operation for speedy analysis

The tool features a visually intuitive user interface (UI) with abundant visuals and diagrams, making it easy to operate even for customers who are not familiar with bearing selection.*3 In addition, analysis results can be easily output as a PDF report and sent via email.

*3 NSK recommends using a PC.

Example of the analysis tool display screen

(1) Top screen

MT-Click!Speedy home screen

*The image above is a demo screen from the development stages and may vary from the actual screen.

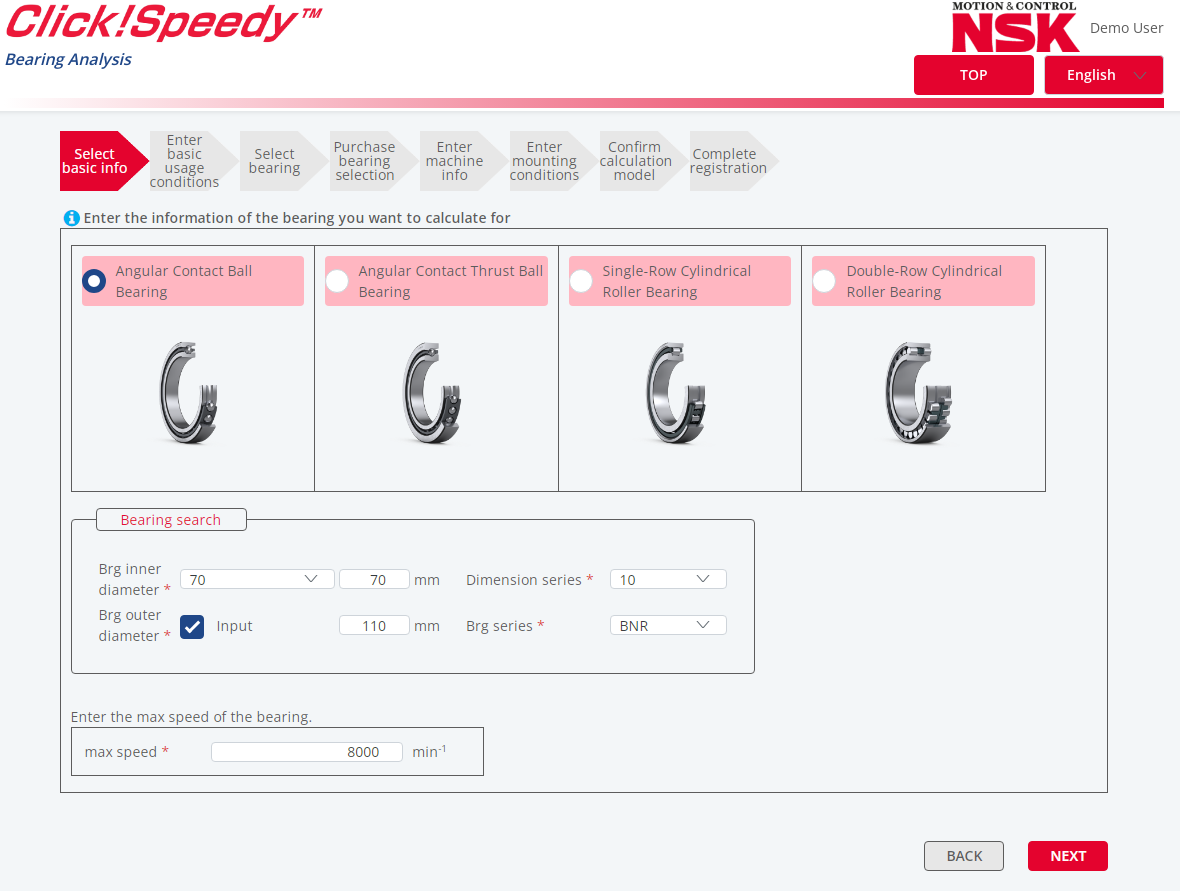

(2) Input screen: Visually intuitive screen for inputting bearing operating conditions (bearing type, dimensions, maximum rotational speed, etc.)

MT-Click!Speedy input screen

*The image above is a demo screen from the development stages and may vary from the actual screen

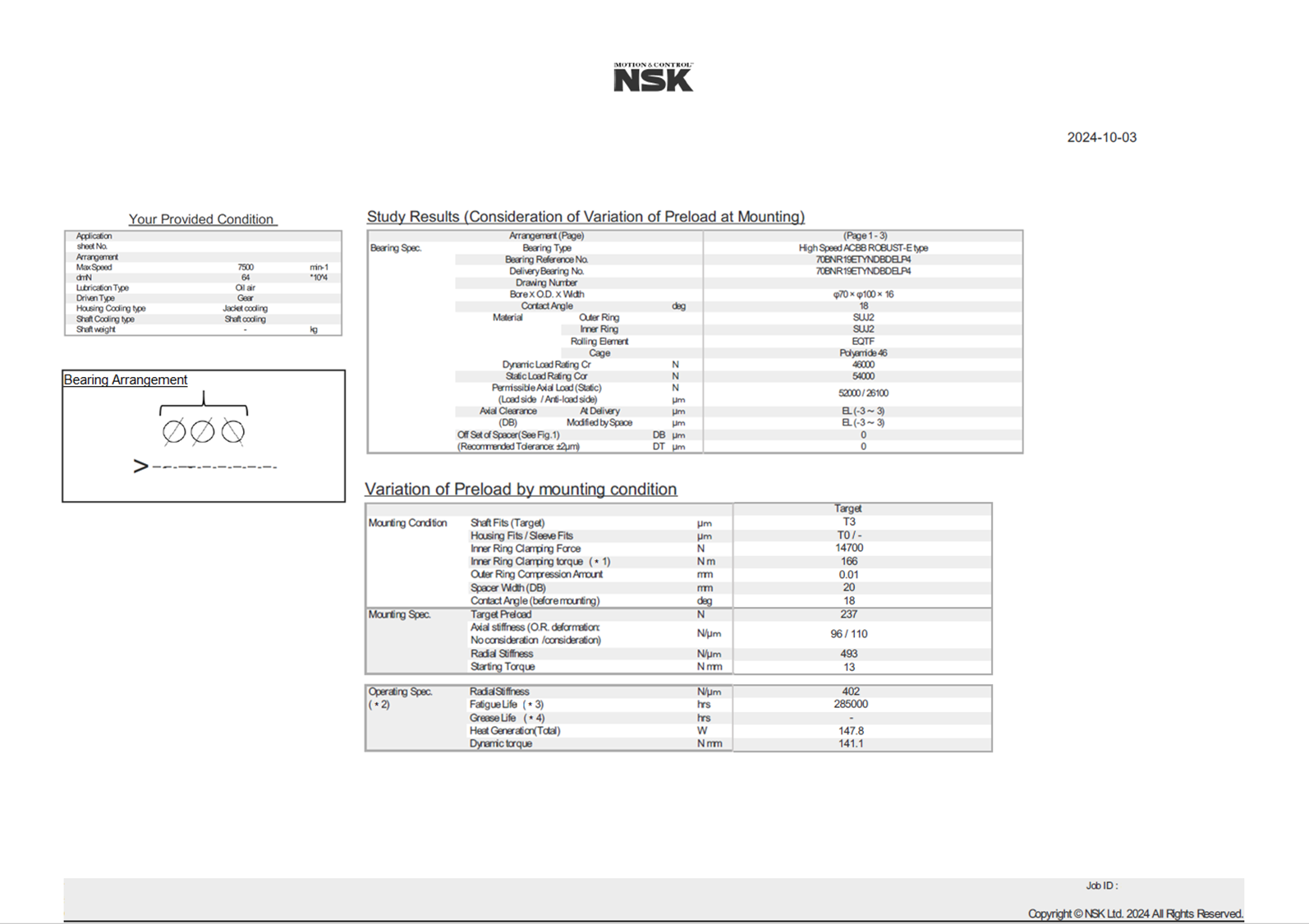

(3) Output results: Analysis result report (including bearing preload, rigidity, life, etc.) can be easily output.

MT-Click!Speedy analysis result report (PDF format)

* The image above is a demo screen from the development stages and may vary from the actual screen.

3) Global support

This tool is a web application and does not require software installation*4, making it compatible with a wide range of devices. Additionally, the PDF report of the analysis results supports multiple languages (supported languages: Japanese, English, German, Korean, Chinese [Simplified], Chinese [Traditional], etc.).

*4 Prior registration is required, including your affiliation, name, email address, and password.

3. Analysis Tool Benefits

With this tool, customers can easily and quickly perform analysis themselves based on NSK’s know-how, allowing them to quickly output analysis results reflecting changes in the bearing operating environment and conditions when changes occur in their design work. This means less time required for customers to select bearings which thereby helps to improve product development speed.*5

*5 For inquiries about evaluation under severe conditions or more detailed reports, please consult with NSK.

About NSK

NSK produced the first bearings in Japan in 1916 and over the past 100 years, it has supported the development of industries worldwide by creating various innovative products and technologies in bearings, automotive parts, and precision machinery. Since the early 1960s, the company has expanded overseas and now has operations in about 30 countries. It ranks third in the world in the field of bearings and leads the world in ball screws, electric power steering, and other products.