NSK Ltd.

Corporate Communications Department

NSK Announces New and Improved Low-Friction Hub Unit Bearing

- NSK has successfully developed a low-friction seal that maintains muddy water resistance by leveraging its core technologies, tribology and analysis.

- Significant reduction in friction (40%) compared to conventional products, helping to extend the driving range of automobiles.

- NSK aims to achieve global sales of 20 billion yen by 2026, primarily targeting electric vehicles.

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) announced today that NSK has developed a new low-friction hub unit bearing. This development has achieved a significant 40% reduction in friction compared to conventional products by adopting a new technology that balances low friction and muddy water resistance in bearings, thereby helping extend the driving range of automobiles (e.g., approximately 1,000 kilometers increase in annual driving distance for electric vehicles that are fully charged on a daily basis*1). NSK aims to achieve global sales for this new product of 20 billion yen by 2026, primarily targeting electric vehicles.

*1 According to NSK findings.

The newly developed hub unit bearing

1. Development Background

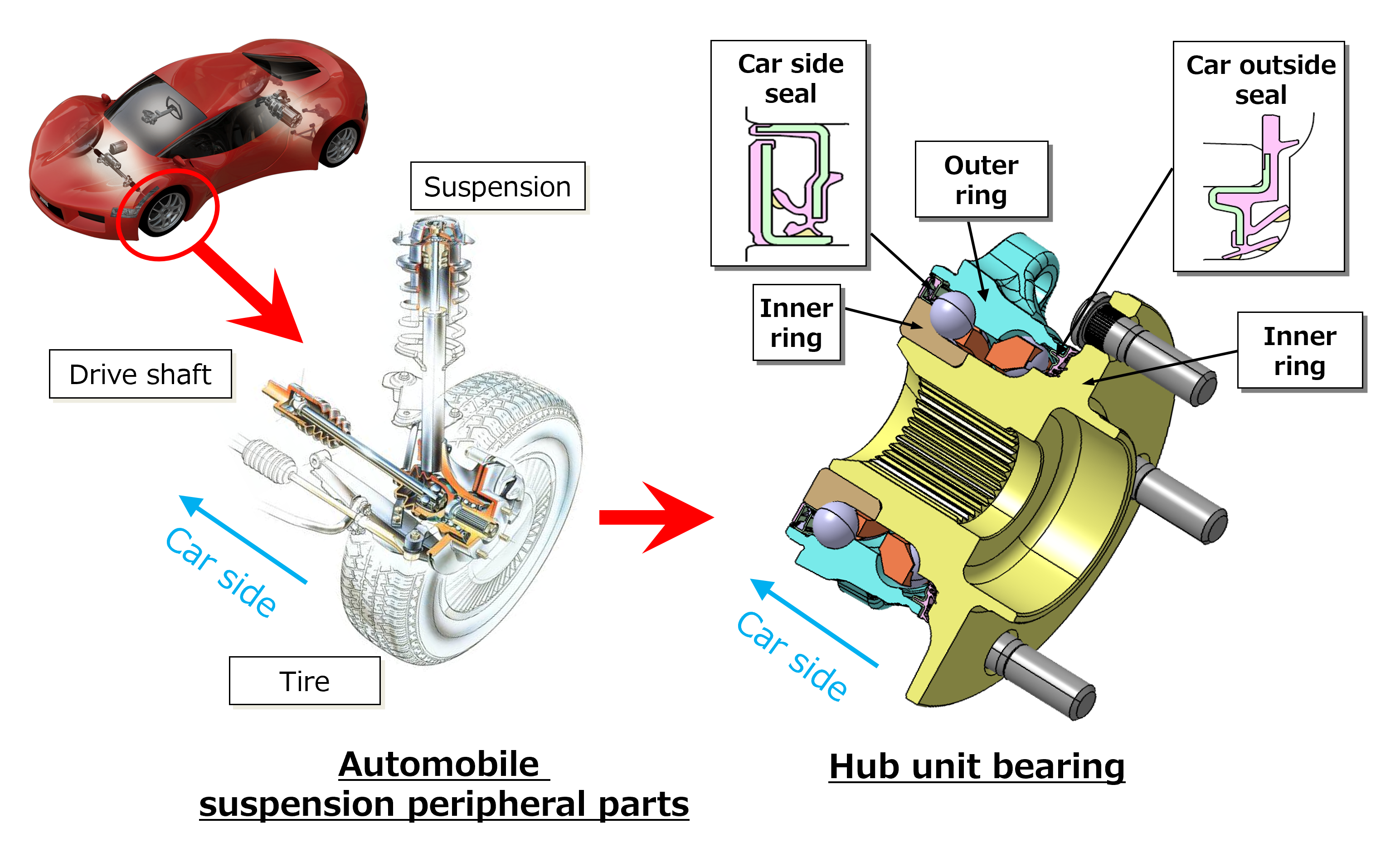

Hub unit bearings are installed close to the wheel and are exposed to harsh environments such as muddy water while driving, requiring high muddy water resistance. In recent years, there has been a growing need for lower friction due to social factors such as decarbonization and rising fuel costs.

In 2020, NSK announced a low-friction hub unit bearing for electric vehicles that achieved reduced friction by using a new type of grease. This time, NSK has focused on seal technology and achieved further reduction in friction while maintaining muddy water resistance compared to conventional products.

2. Technology of the Developed Product

Three new seal technologies have been developed to balance low friction and muddy water resistance.

1) New Technology: Development of Seal Shape

By utilizing tribology expertise and analysis technology to create an appropriate seal shape, NSK has achieved low friction while maintaining muddy water resistance. The new seal has top performance in terms of balancing low friction and muddy water resistance*2.

*2 According to NSK findings.

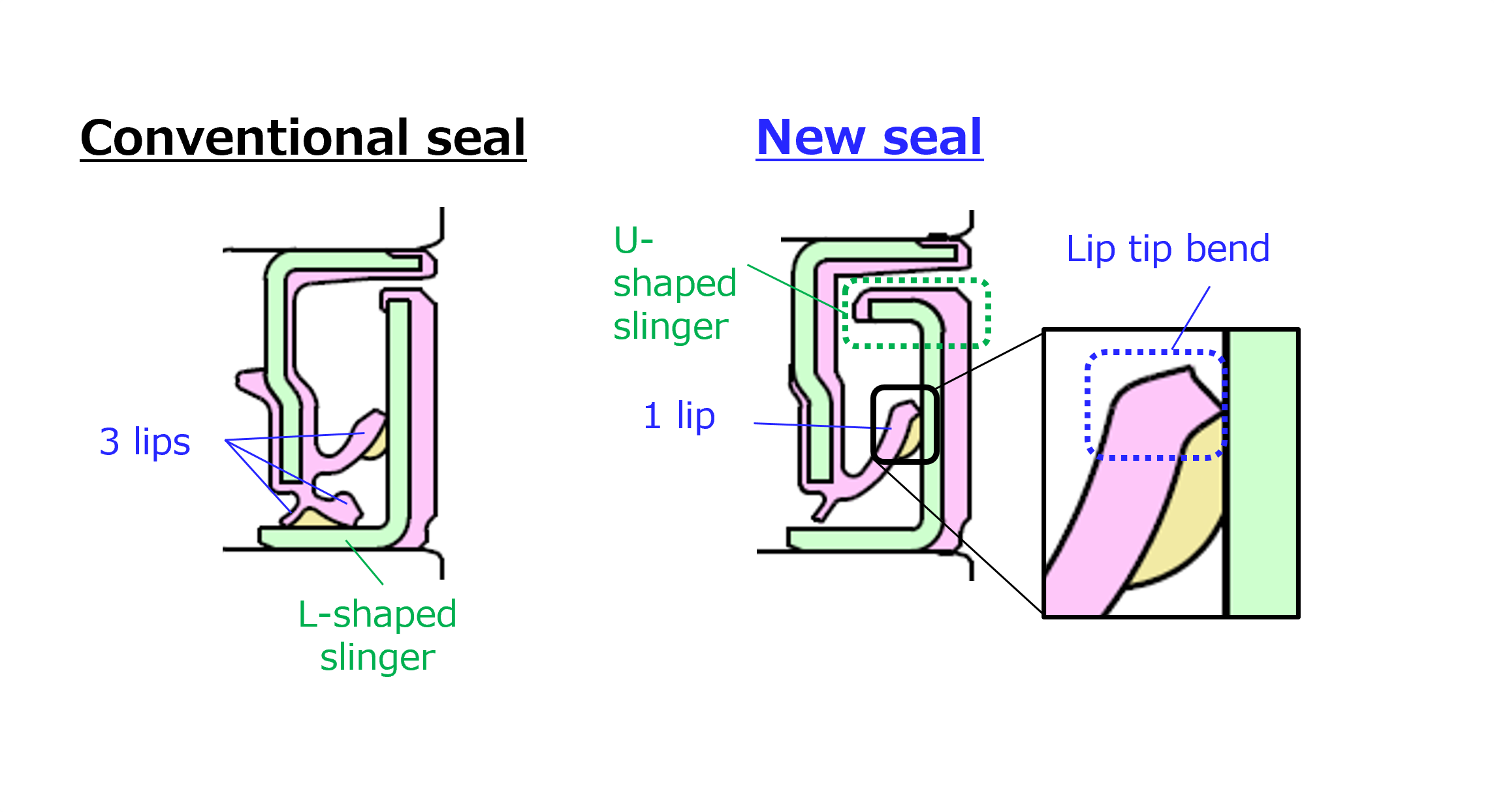

●Reduction in the number of lips: Reducing the number of lips from three to one reduces friction.

●Bending the tip of the lip: Bending reduces the contact width between the lip and the slinger.

●Change in slinger shape: NSK's analysis technology was used to develop a U-shaped slinger with high drainage performance.

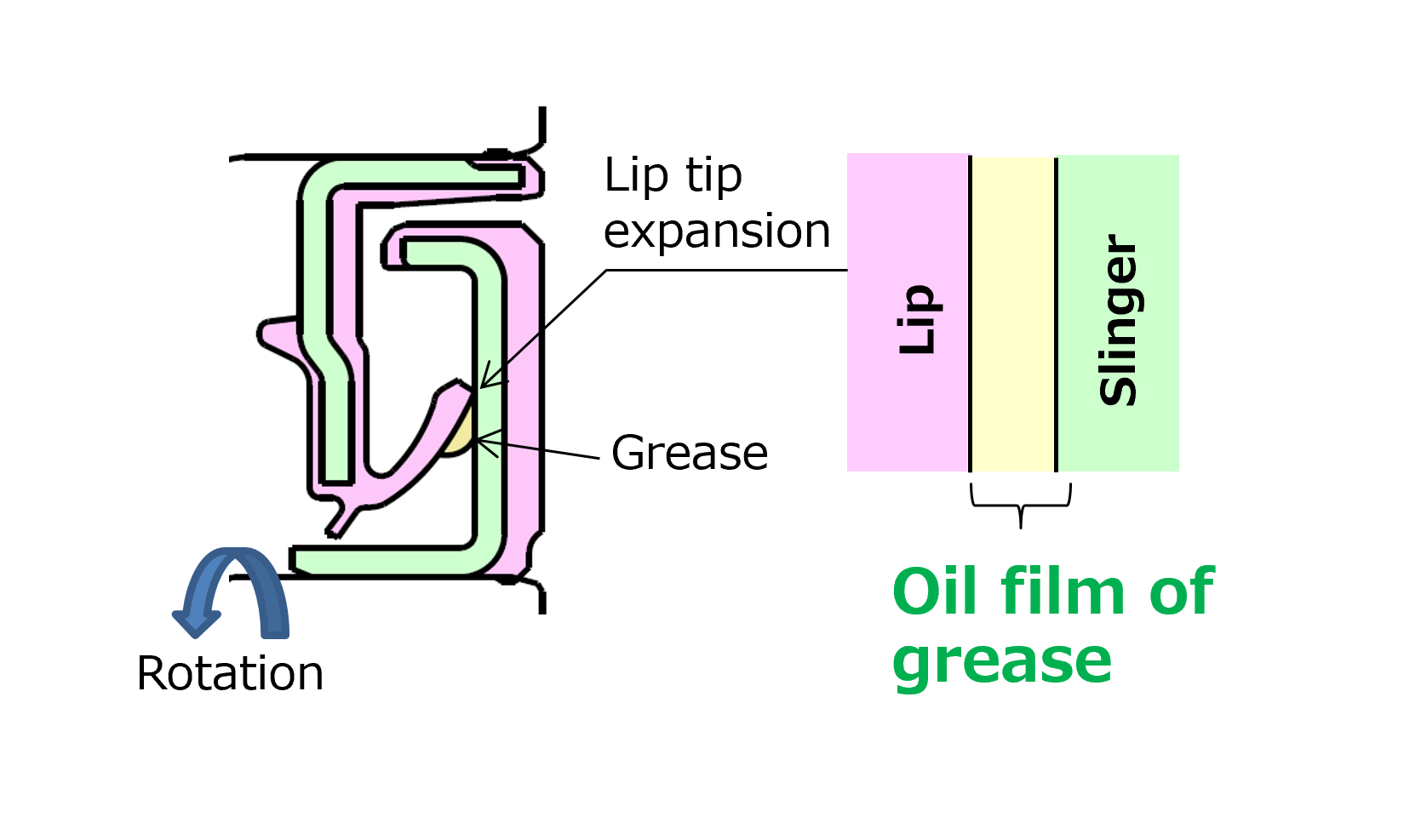

2) New Technology: Development of Seal Grease

NSK lowered friction using tribology expertise to lower the base oil*3 viscosity of the seal grease. This seal grease adopts a polymer as a reinforcing agent to form an oil film of grease. NSK is the first in the world to develop this technology*2.

*3 Base oil: The main component of grease that plays a role in lubrication.

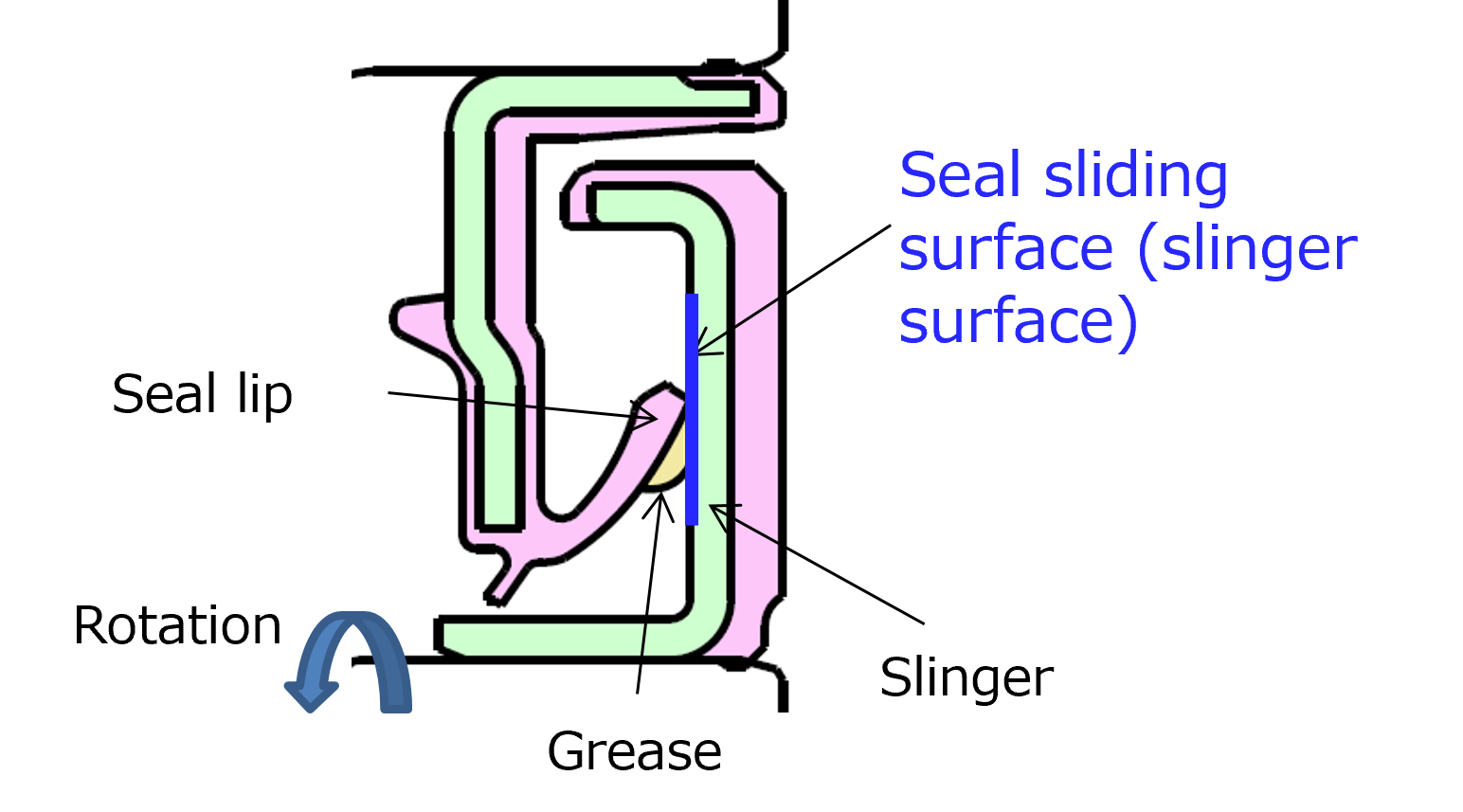

3) New Technology: Development of Seal Sliding Surface*4

Utilizing tribology expertise, NSK was able to apply laser processing to the seal sliding surface. Making the uneven shape of the sliding surface uniform also reduces friction. This is the first time in the world laser processing has been adopted as the processing method of the sliding surface*2.

*4 Sliding: Refers to the movement of objects rubbing against each other, friction occurs during this process. In a bearing seal, the surface where the lip and slinger rub against each other is called the sliding surface.

About NSK

NSK produced the first bearings in Japan in 1916 and over the past 100 years, it has supported the development of industries worldwide by creating various innovative products and technologies in bearings, automotive parts, and precision machinery. Since the early 1960s, the company has expanded overseas and now has operations in about 30 countries. It ranks third in the world in the field of bearings and leads the world in ball screws, electric power steering, and other products.