NSK Ltd.

Corporate Communications Department

NSK Develops ROBUSTRIDE™, a High-Precision Single Row Cylindrical Roller Bearing for Machine Tool Spindles

The new cage design achieves longer bearing life and higher speeds for improved machine tool productivity

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) has developed ROBUSTRIDE™, a high-precision single row cylindrical roller bearing for machine tool spindles that improves machine tool productivity.

This newly developed product achieves longer bearing life and higher speeds by improving grease life and limiting speeds*1. This contributes to reducing the frequency of bearing replacement, expanding the usable rotational speed range in the grease lubrication method*2, which consumes less electrical power and improves the productivity of machine tools. NSK will exhibit this product at the 32nd Japan International Machine Tool Fair (JIMTOF 2024) to be held from November 5 to November 10, 2024, and mass production is slated to start in 2025. NSK’s goal for global sales for this product is 1 billion yen annually by 2030.

*1 Limiting speeds: The maximum speed at which a bearing can rotate stably

*2 Grease lubrication method: A lubrication method in which a small amount of grease is sealed into the bearing when the bearing is assembled into a machine.

Exterior image of ROBUSTRIDE™

1. Development Background

Due to the trend toward decarbonization, attention has been focused on grease lubrication, which consumes less power, as a lubrication method for machine tool spindle bearings. However, with grease lubrication, there is no oil supply during operation, and the grease is easily degraded, resulting in a higher frequency of bearing replacement compared to other lubrication methods and a shorter machine maintenance cycle. Therefore, there has been a need for longer bearing life (improved grease life).

Furthermore, with grease lubrication, grease is particularly prone to degradation at high rotational speeds, resulting in limitations on the usable rotational speed range compared to other lubrication methods. Additionally, there has been a demand for higher speeds of bearings using grease lubrication (improvement in limiting speeds).

2. Technology of the Developed Product

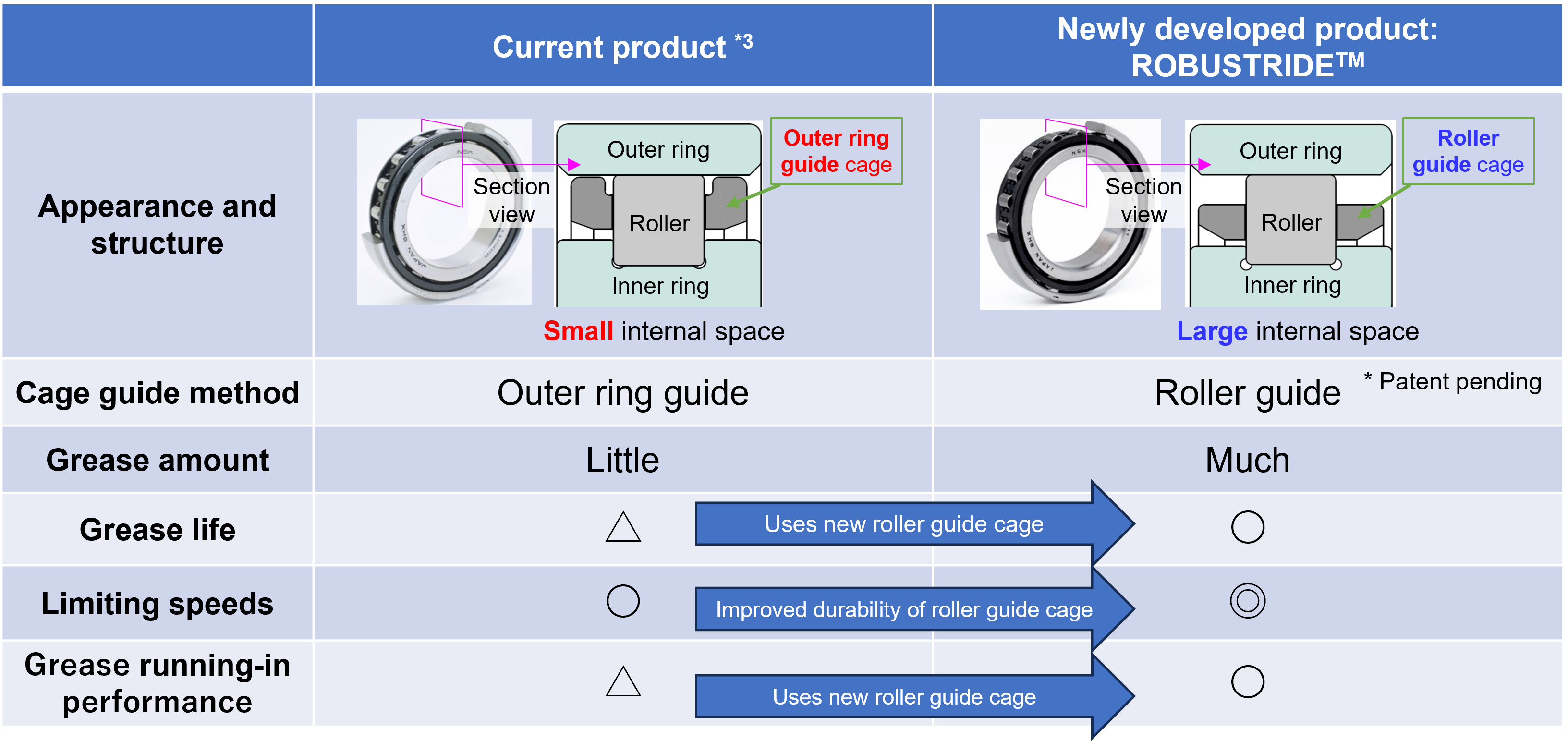

This newly developed product adopts NSK’s innovative developed cage to improve grease life, limiting speeds, and grease running-in performance.

1) Improved grease filling amount ⇒ Improved grease life of the bearing

2) Improved durability of the cage ⇒ Improved limiting speeds of the bearing

3) Improved grease discharge performance ⇒ Improved grease running-in performance of the bearing

Comparison of performance between the current product*3 and ROBUSTRIDE™

*3 Current product: The current NSK Robust series (high-performance bearing series of NSK precision bearings)

3 . Features of the Developed Product

This newly developed product achieves longer bearing life by improving grease life, reducing the frequency of bearing replacement. In addition, by improving the durability of the cage, it realizes higher speeds of bearings using grease lubrication. Furthermore, by shortening the grease running-in operation time*4, energy consumption is also reduced. These features contribute to improving the productivity of machine tools.

1) Improved grease life: Up to approximately 60% improvement compared to the current product

2) Improved limiting speeds: Up to approximately 20% improvement compared to the current product

3) Shortened grease running-in operation time: Approximately 1/3 shorter compared to the current product

*4 Grease running-in operation time: A test run performed to move the grease to the appropriate position when assembling a bearing to a machine. The grease generates heat during high-speed rotation in the position immediately after it is filled, and there is a risk that the bearing will seize up and become damaged.

About NSK

NSK produced the first bearings in Japan in 1916 and over the past 100 years, it has supported the development of industries worldwide by creating various innovative products and technologies in bearings, automotive parts, and precision machinery. Since the early 1960s, the company has expanded overseas and now has operations in about 30 countries. It ranks third in the world in the field of bearings and leads the world in ball screws, electric power steering, and other products.