Services - 16/01/2020

AIP: Improvement pays

NSK produces billions of bearings a year. From cars to aircraft, home appliances to industrial machinery, and computer components to satellites, NSK is all around.

But the company not only manufactures bearings, it also teaches partners and customers how to work with them effectively, an important factor for successful operations and competitive advantage.

Across a four-part series, Andrew ‘Andy’ Bairsto, Global Leader of AIP at NSK, is asked about the company’s AIP Added Value Programme and its benefits for customers, distributors and the environment.

This first Q&A article will cover the key features of AIP as a philosophy and practical toolkit that benefits both end-users and distributors across Europe.

Part 1: What is AIP? – Improvement pays

Part 2: How does AIP drive distributor sales growth?

Part 3: How does AIP reduce total cost of ownership?

Part 4: How does AIP benefit the environment?

Q: Thank you for joining us Andy. Let’s jump straight in, what is AIP?

A: As many NSK customers in Europe will already be aware, AIP is our value creation programme. However, we recently relaunched AIP with the strapline ‘improvement pays’, which conveys an important message highlighting the availability of benefits for all involved. To explain further, for end-users, AIP is proven to increase machine reliability and productivity. For distributors, it unlocks new opportunities in profitable sales growth, simultaneously enhancing the team’s skillset and aiding the transition to selling on value rather than price. It’s a win-win situation for everyone.

Q: So distributors gain from a closer relationship with NSK and share in our specialist knowledge, while end-users benefit from collaborative troubleshooting, resulting in more reliable, cost-effective bearing solutions?

A: That’s right. AIP isn’t a one-off service, it’s a philosophy driving continuous improvement through tangible value-added solutions. This ethos is embodied by the five distinct steps of the AIP value cycle: evaluation, recommendation, implementation, validation and extension.

Q: So how does the AIP value cycle work in practice?

A: It’s probably easiest to start with an example, as today we have many case studies outlining the success of AIP. In one instance, a customer had an issue with the frequent failure of pump bearings and invited NSK to find a solution. Working with a local authorised distributor, the expert team of specialist engineers at NSK began by conducting a comprehensive review of the pump, including its design, application and operating conditions. This evaluation is the first step of the AIP value cycle. Next is ‘recommendation’ where, having identified the issue and given it due consideration, the AIP team proposes a more appropriate type of bearing for the application. As a point of note, although we’re considering a pump in this particular example, AIP can, of course, be applied to any type of machine, system or equipment that uses bearings, including machine tools, industrial gearboxes, paper mill machinery, trains, conveyors, steel mills or machines for agriculture, to list but a few.

Q: And then in the ‘implementation’ step you supply the bearings and, if required by the end-user, help them with installation?

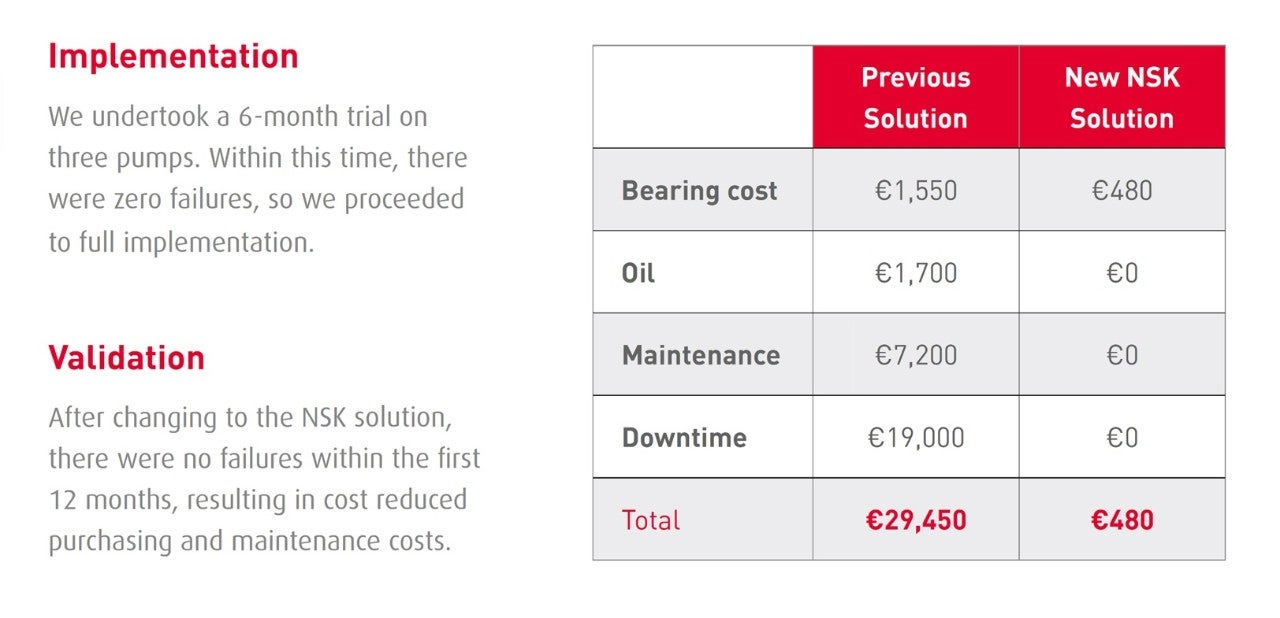

A: Yes. Initially, we perform a test run and, once a proving period has been successfully completed, move up to the full implementation. From there, the fourth step is ‘validation’, where we confirm that the new solution has effectively improved the situation over the long term from a financial perspective by reducing purchasing costs (fewer parts bought), achieving lower maintenance costs and reducing the frequency of failures to eliminate unplanned downtime.

Q. Sounds like a wrap, but there’s still one more step, ‘extension’, right?

A: To summarise, in the first four steps we provide a value-added service to deliver a solution that reduces the frequency of failures. In effect, we lower the end user’s total cost of ownership via fewer replacements, less maintenance and reduced downtime. Everybody loves to save money while improving productivity at the same time. So, in our example, the user of pump bearings was delighted with the result and asked us to evaluate other parts of the plant, a request we receive frequently in our AIP projects across Europe. The final step, ‘extension’, is about driving further cost savings and benefits across all of the customer’s operations, which of course also benefits the distributor and strengthens the distributor-customer relationship. As I said, everybody wins.

Q: I’m starting to understand why ‘improvement pays’. Are any examples of AIP success stories available online?

A: We’re very serious about the benefits of AIP. Our customers really appreciate the programme, and we frequently publish AIP Success Stories on our website describing the benefits delivered in almost every kind of industry. We help customers realise significant cost savings and regularly see costs reduced by 50% or more in applications across Europe.

Q: To put it simply, NSK works directly with authorised distributors to better serve its end-user customers?

A: Remember that the distributor’s customer is our customer; the end-user is using NSK products, so we’re committed to following through and ensuring a quality experience every step of the way. From surveys and inspections to training and selection, AIP is a highly structured programme to partner with distributors and deliver the benefits of our specialist knowledge.

Q: Sounds great. Where can I find more information on AIP?

A: Visit our AIP webpage for brochures and an in-depth overview of the programme. Distributors interested in becoming AIP partners should contact their local NSK representative. You can also follow us on LinkedIn for regular AIP updates.

Picture 1: Andrew Bairsto, Global Leader of AIP

Upcoming articles:

Part 2: How does AIP drive distributor sales growth?

Part 3: How does AIP reduce total cost of ownership?

Part 4: How does AIP benefit the environment?

Picture 2: The five-step AIP value cycle

Picture 3: In this example, significant annual savings were realised

Picture 4: AIP – start improving today to maximise the potential savings

Share