Linear Motion Control - 29/03/2021

NSK linear guides help ETEL bring speed and precision to semiconductor manufacturing

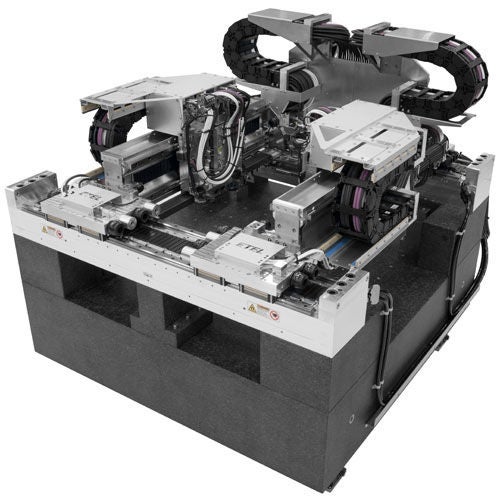

NH series linear guides from NSK are helping a manufacturer of motion platforms for semiconductor manufacturing to provide its customers with a solution that offers speed and precision beyond previous capabilities. Called TELICA, this technology-driven breakthrough from Switzerland-based ETEL S.A. - a specialist in the design and manufacture of motion systems for semiconductors - can benefit any application in this sector that requires a combination of high throughput and high accuracy.

In developing TELICA, ETEL wanted to create a multi-axis positioning platform dedicated to meeting the most challenging requirements of advanced flip-chip die bonding for back-end semiconductor processes, μ-LED bonding, dispensing applications, as well as accurate, high-throughput tasks in the wider electronics market. However, the concept had to go beyond existing capabilities in terms of speed and precision. By design, conventional motion system architectures offer either high positioning accuracy or high throughput, not both.

With these thoughts in mind, ETEL turned to the performance and quality of NH series linear guides from NSK. NH linear guides are renowned for their precision and repeatability at both low and high operating speeds. In addition, control of the preload helps to manage friction levels and long-term rigidity.

Notably, the NH linear guides for ETEL feature NSK’s proprietary LG2 grease. LG2 achieves a reduced emission rate and longer service life in comparison with conventional greases, and lower, more stable levels of force.

Offering unprecedented levels of performance for a multi-axis motion platform, TELICA has met all of ETEL’s aims. The machine delivers very high throughput speeds of up to 10,000 uph (units per hour) for a typical flip-chip die bonding application and positioning accuracy of better than 1µm. Conventional solutions to date offer around 7,500 uph and 3µm.

The mechanical architecture of the TELICA platform is a dual-gantry system that provides motion along three degrees of freedom in the X, Y and Z directions for a total number of eight controlled axes. Using NSK’s NH guides, further capabilities of TELICA machines include: motion speed of 120m/min in the X and Y axes, and 60m/min in Z; acceleration of 4G, 6G and 7.5G in X, Y and Z respectively; and X-Y repeatability (after a Z-axis move) of ±0.25µm or better.

The system allows users to handle the requirements of next-generation advanced packages, such as HBI (Hybrid Bonding Interconnects), FO-WLP (Fan-Out Wafer Level Package) and FO-PLP (Fan-Out Panel Level Package), over a working area of up to 870 x 800 mm.

Assuming continuous 24-hour, 365-day operations, ETEL anticipates that TELICA systems could provide a service life of circa 10 years, which would equate to linear rail life of 50,000 km. There are many reasons why NSK NH series linear guides can provide such performance, including the use of Raydent surface-treatment technology instead of standard stainless steel, alongside close control of friction and vibration levels, and the deployment of LG2 long-life lubricating grease.

About ETEL

Headquartered in Môtiers in the canton of Neuchâtel, Switzerland, ETEL S.A. was founded in 1974. The company is part of the HEIDENHAIN group and 100% dedicated to direct drive technology. With its wide range of linear and torque motors, position and motion controllers and high-end motion system products, ETEL provides a portfolio to meet the stringent requirements of applications in the semiconductor, electronics, automation, medical and machine tool markets.

www.etel.ch

Picture 1): TELICA machines from ETEL deliver throughput speeds of up to 10,000 units per hour and positioning accuracy of 1µm. Photo: ETEL S.A.

Picture 2): NSK’s NH series linear guides are renowned for their precision and repeatability at both low and high operating speeds. Photo: NSK

Share