Bearings - 11/10/2021

Changing to NSK Molded-Oil bearings reduces maintenance costs at a car wash

The operator of a car wash line in Germany repeatedly had to replace bearings in the rotary unions of the system’s wash heads, leading to costs of over €12,000 per annum for spare parts alone. However, maintenance costs were reduced to zero after replacing the bearings with NSK Molded-Oil deep groove ball bearings featuring DDU seals.

An average car wash in Germany cleans more than 110,000 cars every year. In terms of the drive components in the wash bars and heads, the application is equivalent to an endurance test with water and cleaning agent spray. The bearings in the rotary unions of the wash heads undergo the same treatment, and in this case, they were not up to the task.

Personnel at the car wash company had to replace the deep groove ball bearings of the rotary unions several times a year. Therefore, the company contacted NSK to ask for advice on how to lengthen the service life of the bearings. Analysis of the defective bearings quickly revealed corrosion and the absence of grease, which had washed off. The cause: the non-abrasive seals were unable to prevent wash water from penetrating the bearings, thus rinsing away the grease.

NSK suggested replacing the bearings with Molded-Oil deep groove ball bearings featuring DU seals on both sides. In this bearing, a carrier material incorporates the lubricant, releasing it steadily over a long period. As a result, the service life of these bearings (which are available in ball, spherical roller and tapered roller variants) is more than twice that of bearings with grease lubrication, particularly in environments exposed to water and dust. In addition, maintenance intervals are significantly longer because Molded-Oil technology ensures permanent lubrication. And because the bearing runs grease-free without any need for replenishment, the operating environment remains clean.

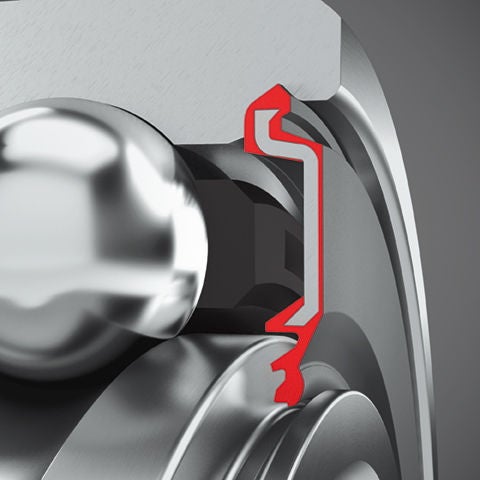

Molded-Oil bearings are available with various seals. For example, the rotary unions at the car wash use bearings with abrasive DU seals on both sides (DDU), reliably preventing water and moisture from entering even when this is a constant feature of the operating environment.

After replacing the bearings, the rotating unions at the car wash ran perfectly. In the first year alone, the company saved more than €11,900 in maintenance costs. The previous costs of over €12,000 for bearings and a very low estimate of labour costs are now set against a one-time investment of €618 for the Molded-Oil deep groove ball bearings. Recouping this investment took less than three weeks.

Picture 1): Bearings in the wash bars and heads of car wash lines have to operate in harsh conditions

Picture 2): Molded-Oil deep groove ball bearings with DU seals on both sides can withstand heavy exposure to water and dust, even in the rotary unions of wash heads

Picture 3): The DU seal acts as an effective barrier, preventing wash water from penetrating the bearing

Share