Linear Motion Control - 27/02/2023

Tyre manufacturer saves almost €100,000 a year with NSK ball screws

When a tyre manufacturer was enduring frequent failures of the ball screw within the air drum of its tyre building machine, the company turned to the expertise of NSK and its HTF series ball screw. By adopting this high-speed, high-load solution, the tyre plant was able to reduce its replacement ball screw purchases by two-thirds, delivering annual savings of €99,128.

Manufacturing for the automotive sector, whether for OEM or aftermarket customers, is highly demanding with little or no margin for downtime. Faced with ongoing failures of the ball screw within the air drum of its process-critical tyre building machine, the manufacturer knew it had to act. The problem was proving extremely expensive, with increased maintenance and lost production impacting output.

To commence the project, the company called upon the expertise of linear motion specialist NSK. As part of a proposition designed to provide the customer with significant added value, experienced engineers at NSK conducted a failed ball screw analysis and machine application review. The team found that the quality and specification of the existing ball screw was not sufficient for the loads exerted by the tyre building machine.

To remedy the situation, NSK recommended a trial of its HTF series high-load, high-speed ball screw, which proved highly successful and led to full technical approval.

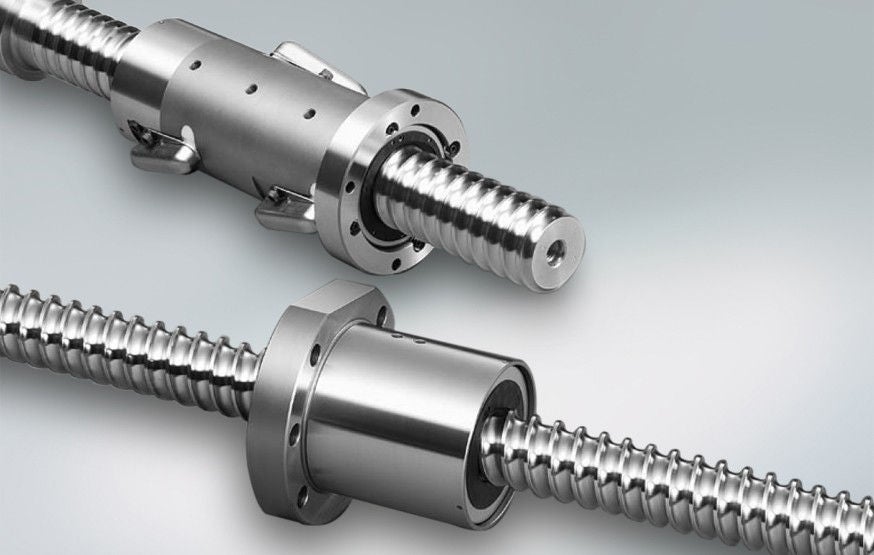

NSK HTF series ball screws feature a special groove profile and a grease-retaining A1 seal that avoids any contamination of the immediate environment with lubricant. As a further innovative feature, these ball screws can be equipped with SRC (Smooth Return Coupling) for fine screw leads or an end deflector recirculation system for medium leads, accelerating feed speed and reducing noise. Any company using HTF series ball screws will benefit from maximum allowable dynamic load and maximum service life due to proper load distribution.

By introducing the tyre manufacturing plant to its HTF series ball screw, NSK managed to extend service life by 50%, and increase uptime and efficiency. By requiring fewer ball screw replacements, the company is saving €99,128 per year. The tyre manufacturer is also benefiting from reduced unplanned failures and, in turn, lower maintenance costs.

Picture 1): A tyre manufacturing plant was experiencing ongoing failures of the ball screw within the air drum of its process-critical tyre building machine. Photo: Shutterstock

Picture 2): Any company using HTF series ball screws will benefit from maximum allowable dynamic load and maximum service life due to proper load distribution. Photo: NSK

Share