Automotive Production

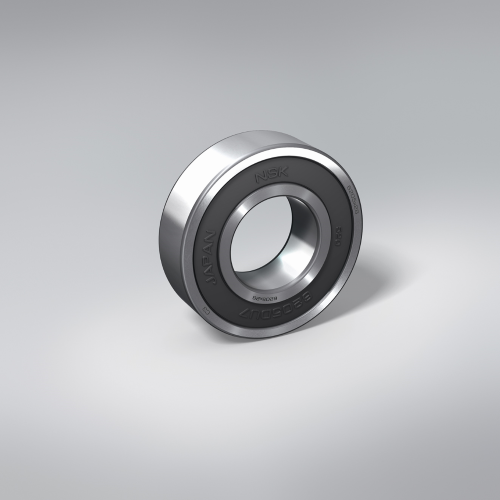

Since it first supplied ball bearings to the Japanese market in 1916, NSK has broadened its range and contributed to all different fields of industry. In particular, the company focused on and moved into the automotive products arena at an early stage. Placing an emphasis on performance and product quality, the company's business developed in tandem with the automobile industry.

Even now NSK is without rivals, supporting automobiles in their three crucial functions: “Running, Turning and Stopping”, thanks to its broad product range.

NSK automotive products are now a globally respected brand. Naturally the company supplies a wide variety of bearings, as well as automatic transmission parts and steering column, joints. Further, it also makes the electric power steering system (EPS), which is ready for the 21st century steer-by-wire technology.

NSK is always upgrading its Motion & Control technologies based on developments in the company's proprietary tribology (friction control technology) and mechatronics technologies that have been built up as a result of the company's rolling bearings business. In this way NSK is able to quickly respond to the needs of its customers around the world.

Various NSK products that are incorporated into automobiles have functionality and performance characteristics that control friction and reduce energy loss. We can say that they themselves are environmentally friendly products that contribute to reduced energy and resource requirements.

Through its new technology, NSK will continue to supply automotive products that are kind to the global environment and that add to vehicle safety and comfort.

NSK Experience & Technology

Since our founding in 1916, NSK has strived to be at the forefront of uncovering and responding to society's needs, offering new motion that no one has ever imagined. Today, NSK's Motion & Control™ can be found almost anywhere in the world. From our homes to high-tech factories, from massive construction machines to tiny medical instruments.

In the automotive industry, in line with our reputation as a top supplier to many of the biggest automakers, NSK solutions have already been adopted in leading electric vehicle models. The future of the automobile is looking bright as we continue to develop innovative products for EV and autonomous driving, as well as all core aspects of vehicle performance — driving, steering, and braking.

Operating conditions: heavy loads

During production processes such as rolling, stamping, cutting and deep drawing, steel is subject to considerable loads in order to shape and machine the metal. The machines used are placed under a great deal of strain.

NSK spherical roller bearings with brass or steel cages from the NSKHPS series

Products from the NSKHPS series (High Performance Standard) boast a long life, even in extreme conditions such as heavy loads and high speeds. They last twice as long as conventional spherical roller bearings, ensuring longer machine running times and lower maintenance costs. The vastly improved cages and optimised internal construction make NSKHPS spherical roller bearings resistant to wear and give them a 20% higher speed limit.

HTF-series ball screws and angular-contact thrust ball bearings from the TAC series guarantee precision and reliability, even when they are exposed to heavy loads.

Production / Body Shell

Operating conditions: maximum-precision robots in contaminated environments with fast accelerations and braking

Conveyors and robots are used throughout the process of manufacturing vehicle shells. When they are assembling the chassis and side panels or welding, the robots have to work with the utmost precision whilst constantly changing speed and direction. To make things even more difficult, the production line is contaminated by welding and can even become damaged.

NH and NS Series of Linear Guides, NSKHPS angular-contact ball bearings, sealed angular-contact ball bearings, bearings for ball screws from the TAC series, Molded-Oil technology for bearings in conveyor belts

NSK’s solution safeguards the robots’ precision, speed and reliability. The components’ long life reduces servicing costs for both robots and conveyors. This is thanks, in part, to NSK’s long-term lubrication unit K1, which enables virtually maintenance-free operations. In addition to this, far less lubricant is needed, which considerably cuts costs.

Operating conditions: environment with high temperatures and contamination, highly conducive to developing corrosion

To guarantee top-quality results – corrosion-resistant paintwork with a perfect finish – the vehicle body goes through a process consisting of various dips and coats of paint. However, the anti-corrosion treatments are highly corrosive for the production line itself. The linear guides used in the manufacturing process can also sustain damage. After leaving the paint shop, the body passes through drying ovens on conveyor belts, which have to withstand extremely high temperatures.

NSK Linear Guides

Thanks to low-temperature chrome plating, the linear guides last more than five times longer than conventional guides with no such coating. Furthermore, the NSK lubrication unit K1 enables very long, maintenance-free running times – even in difficult lubrication conditions. The sealed guide units are ideal for the whole paint shop process.

NSK’s special solid lubricant Molded-Oil significantly reduces downtime caused by bearing failures at medium temperatures.

Operating conditions: precision even at high speeds

Many vehicle manufacturers produce their own engines and transmissions. The processes involved – turning, milling and grinding – demand absolute precision even at high speeds. Increasing use is being made of high-speed spindles, which operate precisely, reliably and cost-effectively.

Sealed angular-contact ball bearings, ROBUST cylindrical and roller bearings and angular contact for high speeds with special patented SHX steel.

All of NSK’s solutions are ideal for the various machine tools used in the production processes for engines and transmissions. They ensure that this machinery runs precisely and enable long, maintenance-free operations, thereby safeguarding high levels of productivity in the process as a whole.

Ultra High-Speed Single Row Cylindrical Roller Bearing - ROBUST Series

High performance cylindrical bearings designed for ultra high-speed applications, such as machining center spindles. >>

Self-Lube® HLT Inserts

These inserts provide opportunities to reduce maintenance, downtime and replacement costs in operation at extreme temperatures. >>

Linear Roller Guide RA Series

In response to the demand for guides with high load capacity, rigidity, high-speed, high-precision, high-quality, as well as to the demand for easy maintenance, rolling guides which have above features are becoming prevalent. In order to meet these requirements, NSK, have developed new Linear Roller Guides and we have been widely accepted for the newest machines. >>

High Temperature Sealed Deep Groove Ball Bearings

Specially created to run in a contaminated environment, and under high temperatures, up to 150°C. >>

Double Row Cylindrical Roller Bearings

Designed to deliver high rigidity in high-speed applications such as lathe spindles. >>

Compact FA-Series

Standard stock series for immediate delivery of BSS Series high-speed, low-noise Ball Screws; next-generation compact Ball Screws offer quiet, high-speed operating performance >>

Twin Drive Ball Screws

TW Series Ball Screws deliver the ideal functionality for twin-drive systems and easily realize the high rigidity >>

Share