Cement

NSK believes that unplanned downtime is not an option — Keep your machinery running all year round!

Working closely with the mining, cement, and ready-mix concrete/aggregate industries, we continue to build on our experience and knowledge of industrial processes, applications, and problem areas. Through close partnerships with equipment manufacturers and end users, NSK engineers work tirelessly to understand requirements and offer reliable solutions. Our products are engineered to overcome unplanned downtime and the inherent problems of contamination and vibration.

NSK’s products, services, and solutions focus on reliability, quality, and reduced maintenance—critical factors to improving uptime and your bottom line. Thanks to extensive knowledge of harsh operating environments, NSK offers bearings uniquely matched to the needs of the cement industry.

Is contamination your biggest problem?

Plant reliability is key to achieving production targets.

Improve the life and performance of your machinery regardless of the conditions - wet, heat, dust, vibration or load.

Contamination is ever present and eventually it wears away at your machinery's effectiveness, often creating unplanned downtime - 80% of premature bearing failure is still the result of poor,or low, lubrication and high contamination levels. Through our four core technologies NSK drives innovation in material, lubrication, sealing and bearing design - creating bearings which resist spalling, flaking, wear and seizure caused by damage contamination.

NSK partnerships provide you with tailored solutions to suit your purpose alongside industry experience and engineering knowledge which will continuously help improve efficiencies within your applications:

Kilns, Grinding Mills, Ball Mills, Pump & Gearboxes, Hydraulic Roll Press, Fans & Air Handling Units, Motors & Conveyors

What can help eliminate failures?

The primary failing point in conveyors is the bearings in the pulleys, followed by the bearings in the motor and gearbox, even though bearings are not always the root cause of the problem. Extending the life of the bearing is vital to extending the life of the conveyor belt.

NSKHPS high performance spherical roller bearings were designed to do exactly this - reduce failure rates & give longer life.

NSK TF - Tough Steel bearings were developed to reduce wear from contaminants extending the production run in arduous areas.

NSK Molded-Oil bearings help you over come your lubrication problems, reducing failures and the need for lubrication maintenance.

NSK Long-life-VS spherical roller bearings offer high operational reliability with little maintenance requirements, designed to undergo the heaviest of stresses, vibration and misalignment.

With this selection of bearings your problems are minimised. NSK engineers can advise you on choosing the most suitable bearing for your machinery, applications, processes & conditions, ensuring you get the most out of your machinery.

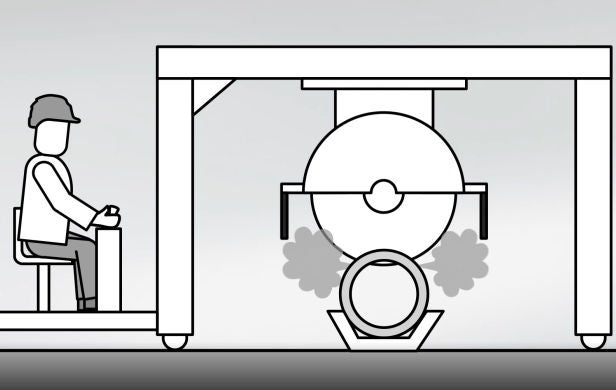

How can you make a pump run forever?

Nothing lasts forever, but you could make them run for longer!

Most companies ignore their pumps until they fail, then the main concern is what is the quickest way to get them running again. Pumps are vital components in the cement & related industry machinery and processes, therefore it is critical that they run efficiently and effectively. With proper maintenance and lubrication they could run for longer.

The most common failure for centrifugal pumps (the most common industrial pump used in the world) are the seals, the lubricant and the bearings. All three points are related, if the seals fail the bearing can fail, if there is not enough lubricant, the bearing can fail quickly afterwards.

By talking with NSK engineers you could benefit from longer life in your pumps - they can advise and help you respond to the problems on your site concerning machinery, sealing, fit, lubrication and maintenance issues & practises to ensure you get the most out of your bearings and therefore pumps.

Real answers to your problems!

Working with you to help keep you competitive in your operating marketplace.

Focusing directly on solving problems that are costing you time and money, NSK's Added Value Programme - AIP has a proven track record of helping customers achieve improved reliability and increased efficiencies. Delivering success to your business through every, or any, stage of the process.

Discover how NSK has helped its customers deliver real benefits to their processes and bottom line through the structured Added Value Programme - AIP.

TF Series Bearings

Designed for outstanding toughness under harsh conditions, combining longer service life & superior resistance against wear, seizure & heat. >>

NSKHPS Angular Contact Ball Bearings

Designed for industrial machinery and applications in pumps and compressors: easy handling, long-life, low vibration and quiet running. >>

Molded-Oil Bearings

Molded-Oil Bearings are lubricated with NSK’s original oil-impregnated material, Molded-Oil, and are suitable for corrosive and dust-contaminated environments. >>

Long-life-Vibrating Screen Roller Bearings

Long-life-Vibrating screen series are engineered specifically to withstand hard working environments & frequent vibration. >>

NSK Success Stories

Customer cost savings is the best reference of our success. Example Success Stories by industry are listed below >>

Technical Enquiry

Looking for a new solution? Fill out the technical enquiry form and one of the NSK technical team members will provide assistance as soon as possible. >>

Troubleshooting

Don't let your bearings fail prematurely or unexpectedly. Save yourself trouble and money with the NSK troubleshooting tools. >>

Share