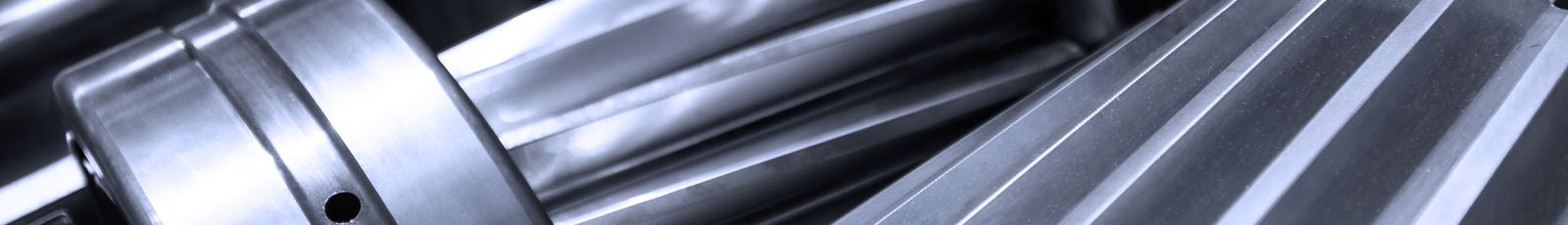

Industrial Gearboxes

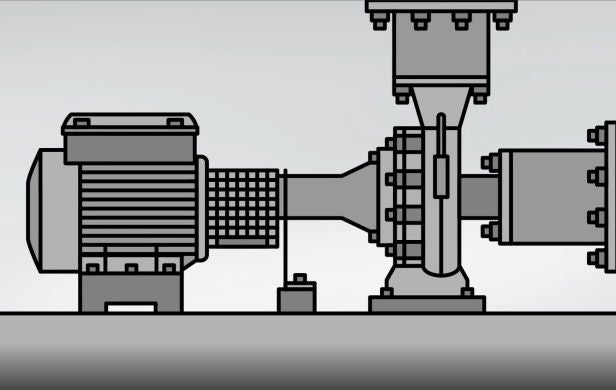

Gearboxes are used in a very wide range of industrial fields. Thanks to the use of gearboxes, a small rotation force (torque) can be used to produce a much greater rotation force, and a slow rate of revolution can be speeded up. In many industries, the gearbox, which is the equipment that transmits mechanical power, is an essential piece of equipment. This step-up unit is the:

- heart of a wind turbine

- transmission in an automobile

- the reduction gears in a Ferris wheel

By supplying bearings for gearboxes such as these in support of their most important function: “revolving,” NSK believes that it can even be said to be supporting the world.

However, because there are many instances where the breakdown of a gearbox would have serious implications, extremely high reliability is demanded. Naturally, NSK seeks to ensure that its designs closely match customer needs, and the company is always aiming to enhance product quality. NSK supplies bearings that offer long life to reduce equipment maintenance costs, can handle high load capacities, and are extremely reliable.

NSK will continue to pool its comprehensive strengths. With environmental issues firmly in its sights, the company will continue product development efforts so that it can offer the next generation of bearings for more efficient gearboxes that can achieve longer life.

Operating conditions: constant torques plus changing speeds

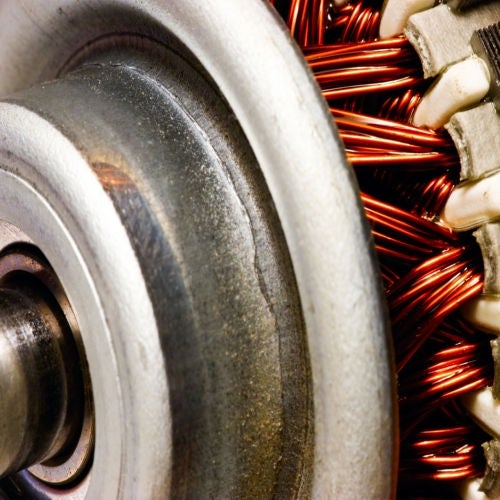

Electric motors and generators place completely different demands on bearings compared to gears. Knocks and fluctuating torques rarely occur. Different speeds are usually the key consideration when it comes to selecting bearings.

Performance classes vary, however. Electric motors and generators in the consumer segment – such as drive motors for washing machines or car alternators – usually have to fit in a very small space and tend to operate under constant conditions. Motors and generators with a higher power density are normally used in industrial plants or to produce power, where considerable load variations are commonplace.

In electric motors and generators, the shaft bearing often has to be insulated from the housing to prevent damage caused by current conduction. With this in mind, NSK has developed electrically insulated bearings with a ceramic coating which are suitable for the conditions associated with these specific mechatronic applications.

NSK can supply the right bearings for all operating conditions and applications, such as extremely compact deep-groove ball bearings which deliver ultra-quiet running along with optimised low energy consumption and require no maintenance.

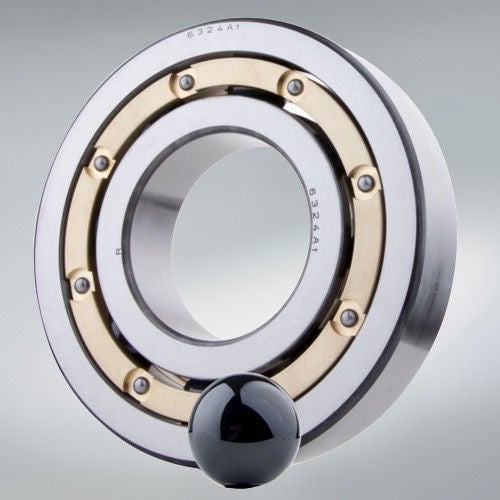

Electrically insulated bearings with a ceramic coating

Some applications are prone to causing bearing damage and premature failure due to electrical corrosion. Electrical corrosion is damage to the raceway resulting from electrical discharges between the rolling elements and the raceway. With its electrically insulated bearings, NSK offers a special product with high insulation resistance to deal with this problem. The bearings’ rings are coated with a layer of ceramic which has a set thickness. This is applied using a special spraying technique designed to ensure that the coating bonds securely to the bearing steel.

Our innovations:

The HR series of deep-groove ball bearings

Hybrid bearings with ceramic balls

NSKHPS Series Roller Bearings

NSKHPS series or high performance standard uses state of the art material technology bearings, offering high speed & load ratings. >>

High Load Capacity Cylindrical Roller Bearing

Developed for gearboxes in large industrial machinery. >>

High Capacity - HR Series

Increased dynamic load rating with larger rolling elements to help improve machinery life performance. >>

Ceramic-Coated Ball Bearings

Optimal for applications that are susceptible to bearing damage and failures due to electrical corrosion. >>

- Technical Tools - Bearings

- Troubleshooting

- Technical Enquiry

Share