Roller Bearings for Paper Machines

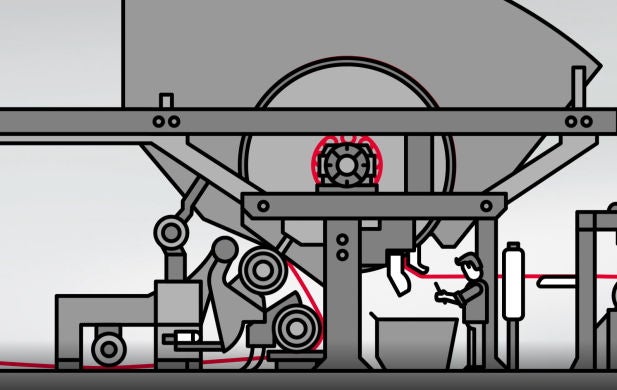

In recent years, the papermaking industry has been making great strides by enhancing the speed and the width of coverage of papermaking machines with the objective of boosting productivity. To reduce the amount of downtime caused by unexpected problems, customers demand high reliability from the bearings that are used in papermaking machines. NSK has developed a range of bearings that meet these demands, and the bearings are used in all sections of modern papermaking machines. In particular, NSK is supporting papermaking with two kinds of bearings:

TL (tough and long life) bearings designed specifically for dryers. These were developed by taking full advantage of the company's material heat treatment technologies.

NSKHPS High Performance Standard Bearings for Industrial Machinery Spherical Roller Bearings developed by integrating NSK's materials, design, and manufacturing technologies.

NSK will continue to develop highly reliable bearings that will lead to further productivity improvements in the papermaking industry, and it will continue to contribute to the development of the industry.

NSK Experience & Technology

The bearings that are used in the dryer rolls of papermaking machines operate in hot environments because high temperature steam is passed through the rolls. The following are examples of the kinds of bearing damage that can consequently arise:

- early abrasion caused by insufficient formation of a film of lubricating oil.

- creep from bearing variance caused by use at high temperatures over long period.

- fracture of the inner ring in the bearing from an increase in fitting stress as a result of temperature differences between the shaft and the ring.

In particular, fracture of the inner ring in the bearing can constitute a serious incident that results in production stoppages. In response, NSK has developed its TL (tough and long life) bearings. Thanks to the use of a special nitrocarburizing treatment for the materials, the fracture strength of the inner ring has been increased and dimensional stability at high temperatures is excellent.

These TL bearings have the overwhelming trust of the market, and they enjoy an unassailable position as the leading choice for dryer cylinder roll bearings.

Operating conditions: Moisture, water ingress and high speeds

Levels of moisture are high in the wire section. This can result in water penetration and bearing corrosion. Water ingress together with the tendency towards ever-greater speeds can lead to premature bearing failure and production stoppages.

NSKHPS series of bearings for very high speeds

To overcome these common problems, NSKHPS range for breast rolls and egoutteur as well as wire drive, wire guide and wire suction rolls also include components such as spherical roller bearings for the paper industry which have a 20% higher limiting speed and last up to twice as long compared to standard products. These paper industry bearings have a special cage design and optimised outer ring surface. Highly accurate precision grades (P55) are also available.

Operating conditions: Low / heavy loads and high speeds

The paper industry demands reliable operation and long service life. Press nips are subject to very heavy loads, while suction press rolls reach very high speeds – up to 2,500 m/min will be possible in the future. Choosing the wrong bearings for paper making machines can quickly lead to raceway damage.

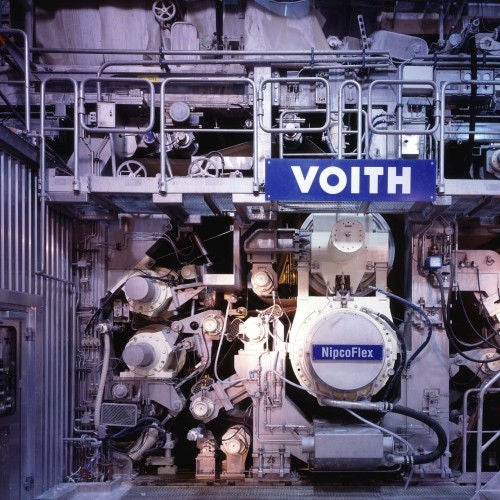

Spherical roller bearings for extremely high loads and speeds in shoe presses

In collaboration with a renowned supplier of equipment for paper machines, NSK has developed, tested and released spherical roller bearings with optimised internal design which are suitable for high, current and future, line speeds in shoe presses

Our Innovations:

Triple Ring Bearings

NSKHPS Series Spherical Roller Bearings

Operating conditions: Very high temperatures, high speeds, heavy loads

Temperatures of up to 150°C are common at the dry end of paper machines. They are also subject to high axial forces and tensile strain. In this demanding environment, the bearing inner ring can crack, causing machine downtime.

TL series spherical roller bearings for high temperatures

NSK’s TL (“Tough & Long life”) series was developed specifically for drying rolls in paper making machines, which run at very high temperatures. Together with special heat treatment, the chemical composition of the steel used makes the inner and outer rings extremely resistant to wear and cracking. This can dramatically reduce downtime and maintenance costs.

Our Innovations:

TL Series Spherical Roller Bearings

Cylindrical Roller Bearings with Aligning Rings

NSKHPS Series Spherical Roller Bearings

Operating conditions: High temperatures, extremely high speeds, heavy loads

Calender rollers are subject to heavy loads and high speeds which can rapidly cause spherical roller bearings to fatigue. Expansion of the bearing inner ring due to heat can lead to cracks which ultimately result in machinery failure.

TL RUB bearings with enhanced running accuracy for high speed and high temperature operation

Thanks to their improved running accuracy and resistance to temperatures up to 200°C, NSK TL RUB bearings are the ideal floating bearing solution for these demanding conditions and future performance upgrades. The bearings’ design enables the calender rolls to expand thermally with no restraints.

Our Innovations:

TL Series Spherical Roller Bearings

Cylindrical Roller Bearings with Aligning Rings

NSKHPS Series Spherical Roller Bearings

Triple Ring Bearings

Triple Ring Bearings

Triple ring bearings, two different types of inner/outer bearing combinations. Especially for papermaking machinery. >>

TL Series Roller Bearings

Specifically designed for dryer rolls in papermaking machinery operating under extremely high temperature conditions. >>

Sealed Spherical Roller Bearings

Promoting a clean working enviroment, these bearings offer long-life performance & reliability under harsh & contaminated conditions. >>

NSKHPS Series Roller Bearings

NSKHPS series or high performance standard uses state of the art material technology bearings, offering high speed & load ratings. >>

Molded-Oil Bearings

Molded-Oil Bearings are lubricated with NSK’s original oil-impregnated material, Molded-Oil, and are suitable for corrosive and dust-contaminated environments. >>

EM Series Roller Bearings

Features high load carrying capability and high performance pressed steel cage. >>

EM Series Roller Bearings

Features high load ratings and quiet running with precision machined tough one-piece cage. >>

Cylindrical Roller Bearings with Aligning Rings

A highly functional, specialised bearing for the non-locating position of continuous casting machines at iron & steel works. >>

Share