Wind Turbines

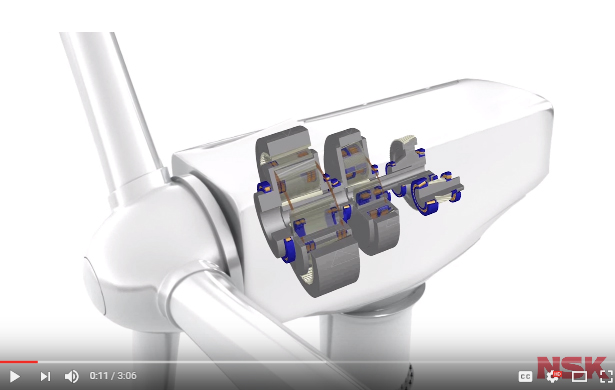

Large wind turbines are enormous machines. Many 2-megawatt class turbines are now being built with blades of around 40 meters in length, and a rotor hub height of 60 to 100 meters. The total weight is over 200 tons. Therefore, the bearings used in wind turbines are very large, with bore diameters of between 100 mm and 700 mm, and even as much as 2 meters in some instances.

Very few manufacturers worldwide, including NSK, can offer the market a stable supply of such large bearings. Suppliers must have both production capability and the ability to provide sales and technical service in key locations around the world, because the wind-turbine industry is now developing on a global scale.

NSK entered the market in the second half of 1990's, supplying the European wind turbine industry. At that time, European companies had a monopoly in the market. NSK currently also supplies bearings to the United States, China, India and elsewhere.

NSK is well known as one of the best bearing suppliers, and currently with NSK bearings used by nine of the world's top ten wind turbine manufacturers, the company is making a substantial contribution to environmental protection.

Operating conditions: variable loads

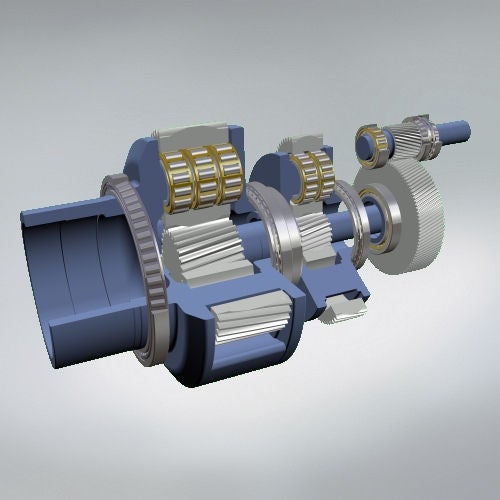

A wind turbine’s main gearbox serves to convert low rotor speed into high generator speed. The gearboxes commonly used in megawatt-class turbines consist of one or two planetary stages and one or two spur-gear stages. Operating conditions for wind turbines make high demands of the bearings used for the individual shafts and gearbox components.

Constantly changing wind speeds mean that the bearings are subjected to strongly varying load conditions. The turbines are switched off when it is calm or there are strong winds and are either stationary or spin at very low speed. The resulting start-up and shutdown procedures lead to high loading. When the turbine is stationary, point loads occur that can cause false brinelling. Idling operation with rotation at very low speed is especially problematic, as the gearbox then runs extremely slowly and often without load. This prevents an adequate lubricant film forming, causing increased slippage of the bearing components instead of rolling friction.

Important parameters include the weight of the gearbox, which due to installation at a height of up to 120 metres needs to be as low as possible, and, of course, the costs. Optimum bearing concept and design is thus essential for competitive gearboxes.

Bearing design by experienced engineers using sophisticated calculation and simulation tools: Besides extreme and maximum conditions, load cycles, lubrication, deformation and thermal response are also taken into consideration. This allows a safe design to be created in order to achieve the desired service life using cost-optimised components.

HR tapered roller bearings, EM Series & EW Series of Cylindrical Roller Bearings with high load ratings

HR taper roller bearings and cylindrical roller bearings from NSK are ideal for main gearboxes as they remain reliable despite changing loads and also have high load ratings. They can be arranged in various different constellations – as locating/non-locating bearings, adjusted bearing arrangements or floating bearings.

Long service lives using BOC (black oxide coating) and patented materials: Black oxide coating is the standard method to reduce the risk of white etching cracks (WEC) in bearings. For high demands the patented special material AWS-TF (Anti White Structure-Tough) is available to reliably prevent damage caused by white etching cracks. To increase the load rating and service life, our STF material (Super-Tough) has proved extremely successful, especially in conjunction with contaminated lubricants.

TF Series Bearings

Designed for outstanding toughness under harsh conditions, combining longer service life & superior resistance against wear, seizure & heat. >>

Spherical Roller Bearings with CAM cage

Spherical roller bearings with CAM cage are designed with a precision-machined tough solid brass cage. >>

NSKHPS Series Roller Bearings

NSKHPS series or high performance standard uses state of the art material technology bearings, offering high speed & load ratings. >>

EW Series Roller Bearings

Features high load carrying capability and high performance pressed steel cage. >>

EM Series Roller Bearings

Features high load ratings and quiet running with precision machined tough one-piece cage. >>

Ceramic-Coated Ball Bearings

Optimal for applications that are susceptible to bearing damage and failures due to electrical corrosion >>

Extend Bearing Life with Tough Steel

NSK Solutions for the Wind Industry

NSK Success Stories

Customer cost savings is the best reference of our success. Example Success Stories by industry are listed below >>

Troubleshooting

Don't let your bearings fail prematurely or unexpectedly. Save yourself trouble and money with the NSK troubleshooting tools. >>

Technical Enquiry

Looking for a new solution? Fill out the technical enquiry form and one of the NSK technical team members will provide assistance as soon as possible. >>

Share