Success Story

Industry: Steel & Metals

Application: Air Recirculation Fan

Cost Savings: € 393 706

Introduction

A customer experienced bearing failure on an Air Recirculation Fan application within a ore preparation plant. This had been a regular problem and compressed air cooling was applied to try and reduce high bearing running temperature.

NSK Engineers carried out an Application Review including a temperature survey of the fan and bearings, revealing major issues with incorrect fitting of the bearings, over lubrication and inadequate sealing arrangement. NSK recommended using NSKHPS Spherical Roller Bearings within NSK SNN Plummer Blocks and NSK Labyrinth seals, along with recommendations for correct fitting and correct lubrication intervals and quantities.

A trial was conducted resulting in no bearing failure for more then 12 months and the removal of the compressed air cooling generating a significant cost saving for the customer.

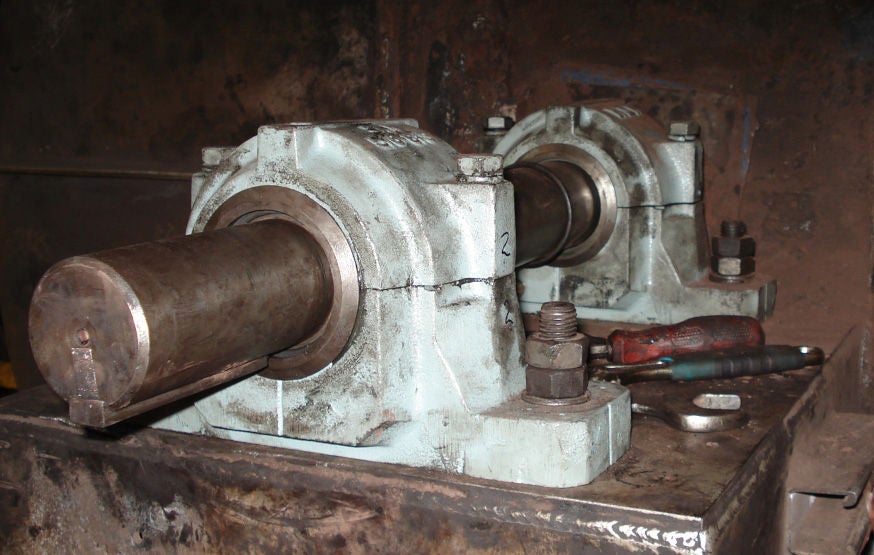

- Air Recirculation Fan

- NSK HPS SRB and NSK SNN Plummer Block

Key Facts

- Air Recirculation Fan

- Overheating of bearings

- Incorrect fitting

- Incorrect lubrication amounts and frequencies

- NSK Solution: NSKHPS Spherical Roller Bearings within NSK SNN Plummer blocks and Labyrinth seals

- Significant cost saving generated by removing the need for compressed air cooling

Value Proposals

- NSK engineering conducted an Application Review including a Temperature Survey and a Bearing Condition Report

- NSK engineers recommended NSKHPS Spherical Roller Bearings in combination with SNN Plummer Blocks and Labyrinth seals and suggested changes in the lubrication amount and intervals

- Trial conducted, with NSK Engineering overseeing the installation and implementation of NSK recommendations

- The customer benefited from increased productivity, reduced maintenance costs and the removal of compressed air resulting in a significant cost saving

Product Features

- Highest load rating SRB's

- Optimum raceway design & surface finishing

- Brass cage design (CAM) or strengthened steel cage (EA)

- High cleanliness Z-steel

- Temperature stability: up to 200° C

- 40 mm to 260 mm bore size

- Up to twice the operating life

- Up to 20% higher limiting speed

- Dynamic load rating: 25% higher

- Lower maintenance cost and improved productivity

- High load rating enables downsizing

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Costs of lost production: €8.400/hour x 36hours shift due to bearing failure | € 302.400 | Costs of lost production: No downtime | € 0 | |

| Engineering Costs: €42/hr x 36hours x 2 persons due to bearing failure |

€ 3.024 | Engineering Costs: Manpower, fitting of NSK bearing €42/hr x 8hours x 2 persons | € 672 | |

| Other Costs: Cost of compressed air per year | € 88.954 | Other Costs: No compressed air used | € 0 | |

| Bearing Costs: Bearing cost | € 750 | Bearing Costs: Bearing cost | € 750 | |

| Total Costs | € 395 128 | € 1 422 | ||

Reference:SS-E-2052

Share