Success Story

Industry: Food & Beverage

Application: Band Cutters in a Dough Machine

Cost Savings: € 206 112

Introduction

A bakery was experiencing regular failures on their linear guides on band cutters. The existing linear guides were Armoloy coated and used food grade grease but they were not holding up to the required performance standards. The bakery was looking for a linear guide with increased speeds and longer service life to meet increased production. NSK proposed a stainless steel Linear Guide, high speed series with food grade K1 lubrication unit.

- Bakery

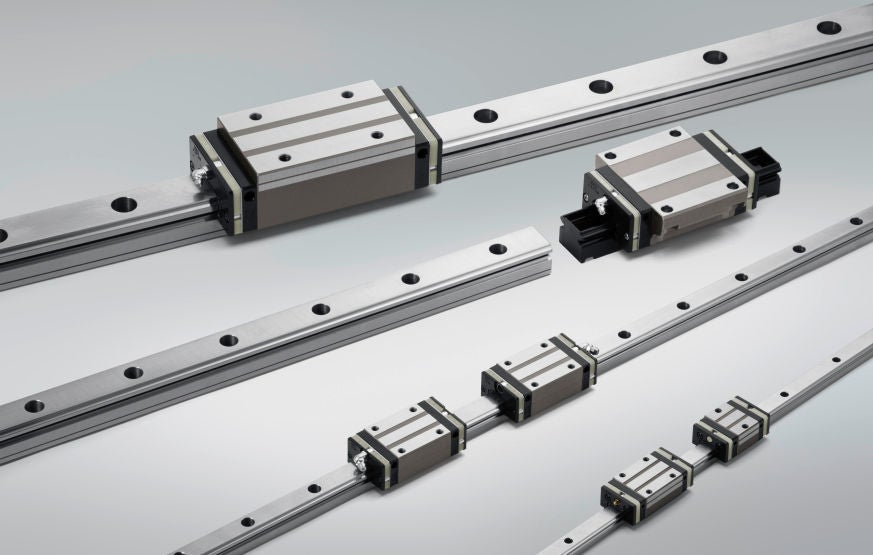

- NH/NS Linear Guides

Key Facts

- Dough machine in a bakery

- Customer was using linear guides with Armoloy coating

- The existing technology was not holding up the performance standards needed

- The Linear Guides on the band cutter needed to be replaced every 3 weeks causing excessive maintenance, downtime and lost production

- NSK solution: Stainless steel Linear Guide high speed series with Food grade K1 Lubrication Unit

- The maintenance costs were reduced and a cost saving was achieved

Value Proposals

- After inspecting the failed linear guides, NSK proposed the use of Stainless Steel NH/NS Series Linear Guides.

- The previous supplier was using Armoloy coated linear guides which were not holding up in the application.

- The bakery was also looking to improve the speed of the application from 250 cycles per minute to 310.

- A trial for one set of guides was agreed.

- Although the cost of the linears guide was double, the life time was ten times longer, increasing output and decreasing downtime.

- A resultant cost saving was agreed with reduced maintenance time.

Product Features

- High-speed design as standard

- High level of precision in different classes

- Self-aligning feature: accommodates misalignment and minimizes internal loads

- Quiet running

- Various preload categories

- Unlimited rail length as individual sections can be used together

- Optimum absorption of impact loads

- First-rate running characteristics and easy assembly

- Higher load ratings make it possible to double service life

- Clear product range due to standardisation

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Linear guides replacement costs: - 5 machines every 3 weeks |

€ 77.962 | Bearing Costs: Linear guides replacement costs: - 5 machines every 8 weeks |

€ 13.156 | |

| Costs of lost production: 4 hours x 450€; 3 weeks replacement intervals |

€ 155.924 | Costs of lost production: 4 hours x 450€; 32 weeks replacement intervals |

€ 14.618 | |

| Total Costs | € 233 886 | € 27 774 | ||

Reference:SS-E-0019

Share