Success Story

Industry: Food & Beverage

Application: Cereal Baggers

Cost Savings: € 64 625

Introduction

A cereal manufacturer was experiencing regular problems with their Linear Guides on their cereal bagging machinery. NSK investigated and found that this was due to cereal dust entering the guide carriage and causing early failure of the unit due to lubrication contamination. The problem was occuring on a monthly basis with consequent high maintenance and lost production costs.

- Cereal Manufacturing

- NSK K1 Lubrication Unit

Key Facts

- Cereal bagger application

- Failure of Linear Guides

- Dust and cereal contamination

- Original Linear Guides lasting 1 month

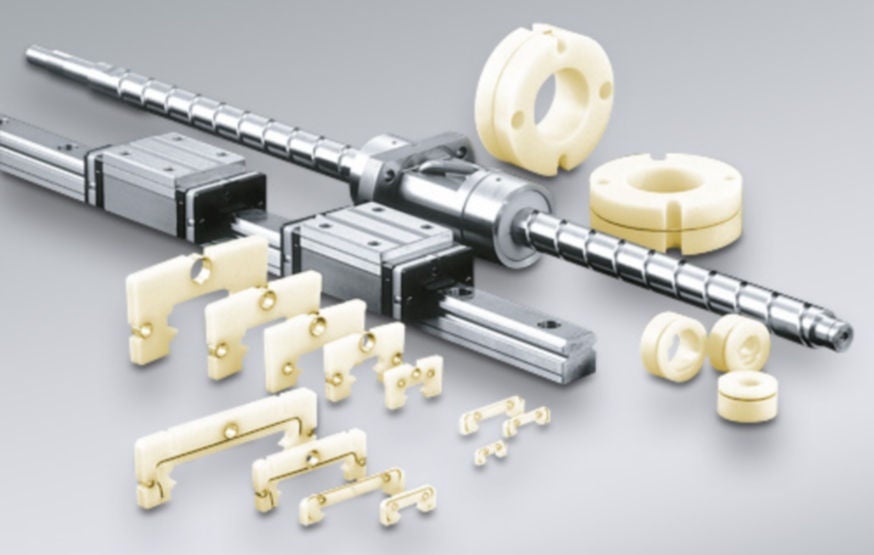

- NSK solution: Linear Guide with K1 Lubrication Unit

- Linear Guide lifetime extended by up to 12 months

- Reduced maintenance and equipment downtime resulting in significant cost savings

Value Proposals

- NSK Engineer reviewed the application following repeated failures experienced by the customer

- An Application Review was completed and the NSK K1 Lubrication Unit was proposed together with a new guide and rail assembly

- A trial of the NSK solution was carried out which resulted in a minimum of 1 year maintenance free operation

Product Features

- Long-term, maintenance-free operation

- Reliable & effective sealing function, also in highly polluted environments

- Cost-saving solution

- Applicable to all Linear Guide models

- Available in accordance with the FDA

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Engineering Costs: Maintenance personnel hourly cost: € 1.375 x 4 machines = € 5.500 12 repairs manually x € 5.500 |

€ 66.000 | Engineering Costs: Annual maintenance: € 1.375 x 1 hour = € 1.375 1 repair per year |

€ 1.375 | |

| Total Costs | € 66 000 | € 1 375 | ||

Reference:SS-E-0017

Share