Success Story

Industry: Steel & Metals

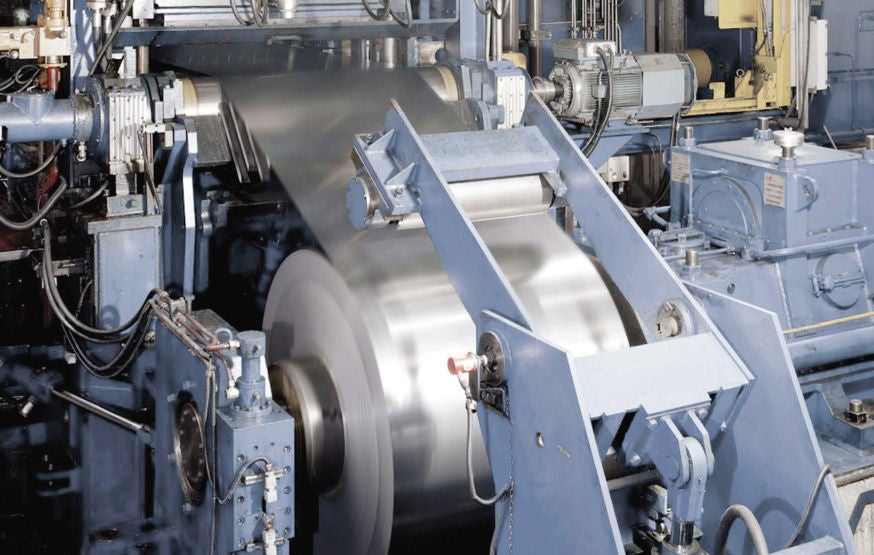

Application: Cold Rolling Mill

Cost Savings: € 16 300

Introduction

A steel manufacturer was experiencing continued failures of bearings on their Cold Rolling Mill. NSK engineers conducted an application review and found the highly contaminated operating conditions were leading to unexpected failures. This resulted in costly unplanned shutdowns and a reduction in production ratios. NSK STF bearings were proposed, which are made of a long-life Super-Tough Steel, specially to combat debris contamination in the lubricant. After a four month running trial, the bearings were sent back to factory for inspection. The laboratory found a residual life between 29-50 months. To date the customer has replaced the bearings once per year during the annual scheduled maintenance.

- Cold Rolling Mill

- Long-Life Super-Tough Spherical Roller Bearings

Key Facts

- Cold Rolling Mill

- Highly contaminated operating conditions

- Extremely short lifetime of bearings : 3-4 months

- The analysis of bearings and grease sample revealed that contamination is the reason for the failure

- NSK Solution: Long-life Super-Tough Steel, Spherical Roller Bearings

- Longer life and superior resistance against wear, seizure and heat

- Significant increase of lifetime from 3-4 months to additional 29-50 months

- Cost saving realised

Value Proposals

- The NSK Technical Department analysed grease samples and inspected the bearings to find the root cause of failure

- NSK Engineers recommended Spherical Roller Bearings in Super-Tough Steel

- After a four month trial (equivalent to the original bearing lifetime), bearings were disassembled and returned to the plant for analysis

- The results showed that the bearing still could work for long time (10 times the initial lifetime)

- Significant cost savings were achieved based on reduced bearing replacement rate, less unexpected line stops, less manpower due to line stops

Product Features

- Special material

- Innovative heat treatment technology

- Outperforming standard bearing steel

- TF, NTF, HTF STF, WTF – material to cater to all your environments

- Up to 10 times service life with contaminated lubrication

- Up to twice the service life under clean lubrication

- Up to 4 times the service life at 160°C

- Less than one-third the rate of wear

- 40% improvement in seizure resistance

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Costs for standard Spherical Roller Bearing per year | € 9.600 | Bearing Costs: Costs for Super-Tough Steel Spherical Roller Bearings per year | € 3.200 | |

| Costs of lost production: Three hours/stop to replace bearings Three unexpected stops/year |

€ 9.000 | Costs of lost production: No unexpected downtimes Bearings are replaced in the annual scheduled maintenance |

€ 0 | |

| Engineering Costs: Three hours/stop to replace bearings Three unexpected stops/year |

€ 1.200 | Engineering Costs: Mounting Costs Included in the annual scheduled maintenance |

€ 300 | |

| Total Costs | € 19 800 | € 3 500 | ||

Reference:SS-E-7004

Share