Success Story

Industry: Steel & Metals

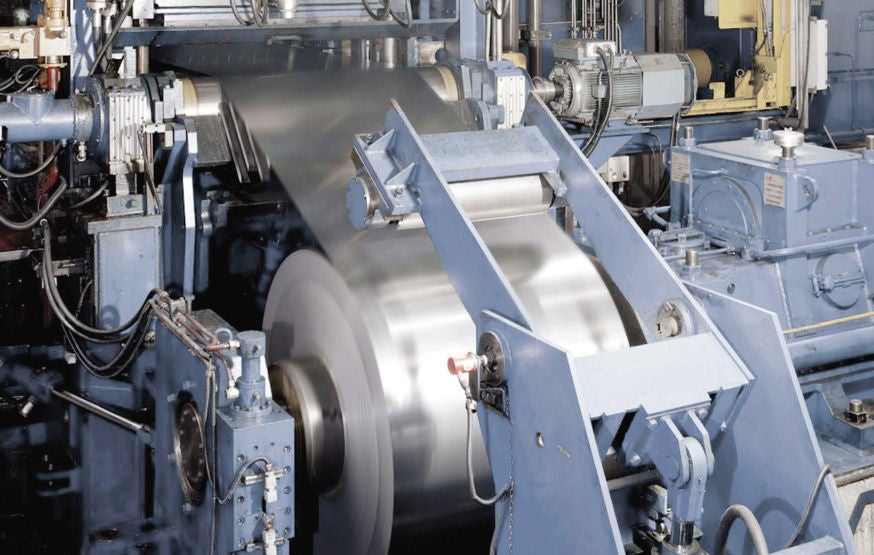

Application: Cold Rolling Mill

Cost Savings: € 26 400

Introduction

A major steel producer was not satisfied with the performance of the four-row tapered roller bearings that were installed in its cold rolling mill: steel shavings from the production process were getting into the bearings and having a detrimental effect on reliability. NSK performed a detailed analysis of the bearings on site together with a failed bearing and lubrication review. This prompted a recommendation to utilise NSK’s Tough technology steels which have a far better resistance to damage caused by debris ingress.

- Steel foil

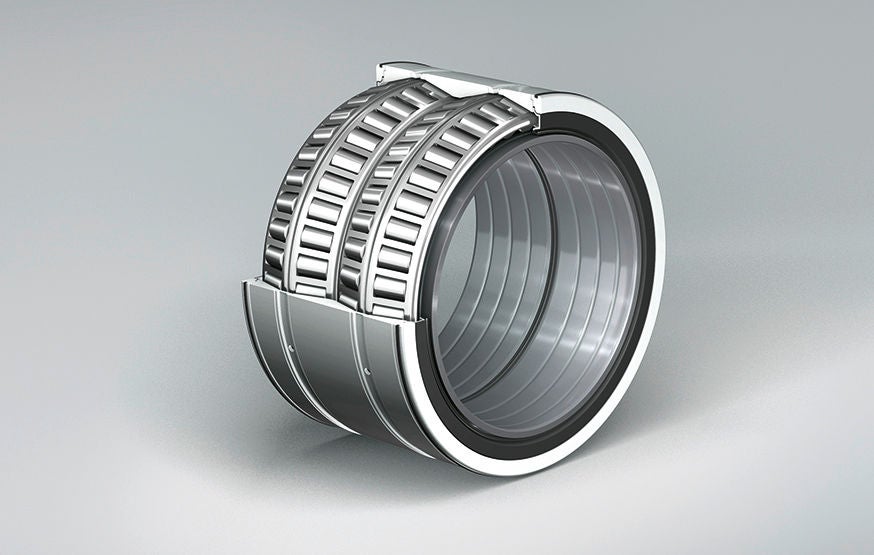

- 4-row WTF (water tough) bearing

Key Facts

- Cold rolling mill

- Damage of the bearings due to ingress of steel shavings from the production process

- NSK solution: Bearings of WTF steel

- More than 3× longer life-time

- Reduced downtime

- Cost savings for bearings and maintenance

Value Proposals

- Analysis of the bearings, the grease, the structure and the design of the billet mill

- NSK bearings made of WTF steel are designed for extreme operating conditions such as those involving solid and liquid contamination

- Technical support including on site engineering consultancy and lab based bearing analysis

Product Features

- Steel material technology

- Special NSK heat-treatment technology

- Optimum chemical composition design technology

- Available for four-row cylindrical and four-row tapered roller bearings

- Bearing life is 3 times longer than that of conventional bearing

- Reduced non-metallic inclusions on raceway surface inhibiting generation of surface cracks

- Grain boundaries have been strengthened to help prevent the propagation of cracks

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Costs of lost production: Bearing Life of the previous bearings: 4 months Lost production costs: € 1.000/h downtime × number of replacements × 4 unexpected downtimes per year |

€ 44.000 | Costs of lost production: Bearing Life of the new bearings: 12 months Lost production costs: € 1.000/h downtime × number of replacements × 1 unexpected downtime per year |

€ 17.600 | |

| Total Costs | € 44 000 | € 17 600 | ||

Reference:SS-E-7003

Share