Success Story

Industry: Cement

Application: Concrete (sett) thickener

Cost Savings: € 32 100

Introduction

A paving producer in Poland was experiencing frequent breakdowns due to bearing failures in a vibrating thickener machine. The bearings were mounted in an electric motor which supported unbalanced weights providing the vibration. In a period of 4 months the customer experienced 10 failures and each time it took 2 hours to replace the bearings. The existing bearings were experiencing grease leakage and high operating temperatures in excess of 110°C. NSK engineers performed an application review and recommended that the existing shielded bearings be replaced with NSK high integrity fluoride rubber contact seals.

- Vibrating Thickener

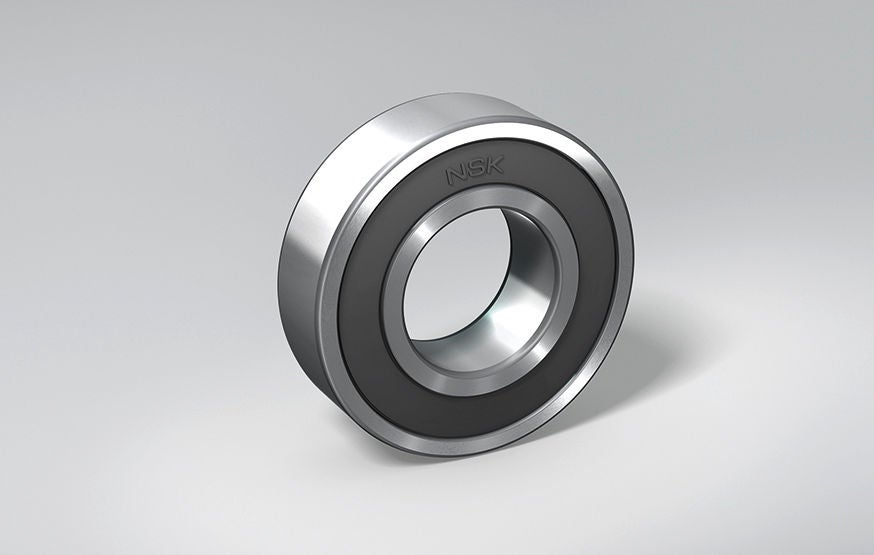

- High Temperature Sealed Deep Groove Ball Bearings

Key Facts

- Concrete (sett) thickener

- High temperature and vibrating conditions

- Grease leakage and high temperature identified as cause of bearing failure

- NSK solution: Deep Groove Ball Bearings with high temperature fluorine DDU seals and special material rings with increased clearance

- Extended lifetime resulted in zero maintenance requiremement after NSK bearings were fitted

- Cost saving based on reduced failures and minimum maintenance requirement

Value Proposals

- The customer experienced many failures in a vibrating motor application. NSK engineers performed a failed bearing analysis which showed grease leakage and high operating temperatures as the cause

- An application review showed that the existing shielded deep groove ball bearings were inadequate. NSK recommended high temperature contact seals in combination with special material rings and C3 clearance

- A trial was conducted on the NSK options and the results showed zero failures in the second 4 months period

- This resulted in a significant reduction in maintenance costs, improved productivity and zero lost production providing a large cost saving for the customer

Product Features

- Steel Cage

- Heat stabilised rings

- C3 Internal clearance

- High temperature grease

- High performance in contaminated environment

- Temperature stability: up to 150°C

- Longer bearing life through superior seal performance (Viton® Seals)

- Reduced noise level "E" class for electrical applications

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Regular bearing failure - up to 20 per 8 months season | €200 | Bearing Costs: No bearing failures within a 4 months season | €100 | |

| Engineering Costs: Maintenance: 20 electric motor à 100 € each | €2.000 | Engineering Costs: No maintenance within a 4 months season | €0 | |

| Costs of lost production: Lost in production per year: 40 hours à 750 € each downtime | €30.000 | Costs of lost production: No lost of production within a 4 months season | €0 | |

| Total Costs | € 32 200 | € 100 | ||

Reference:SS-E-5002

Share