Success Story

Industry: Steel & Metals

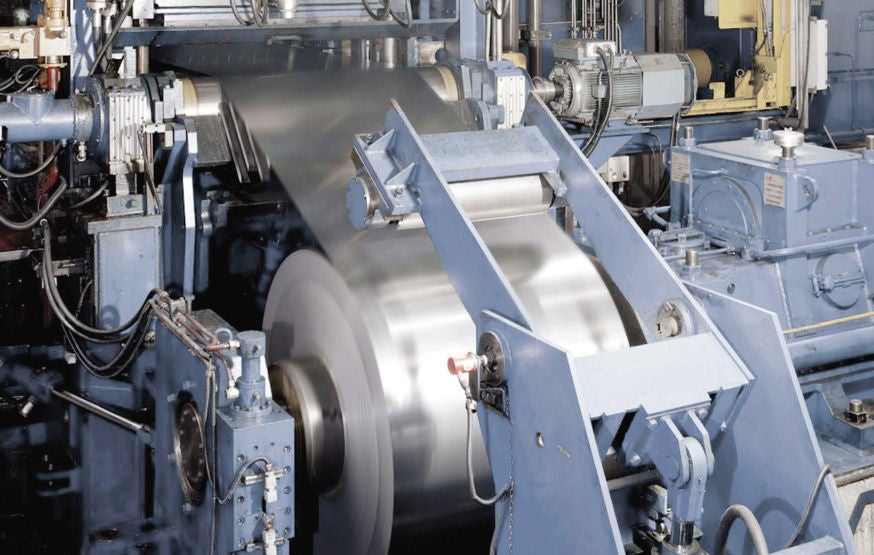

Application: Rolling Mills

Cost Savings: € 46 190

Introduction

The rod mill chocks in the plant of a steel manufacturer were fitted incorrectly with the incorrect spacers, causing failures and the need to source high cost urgent replacement bearings. Maintenance staff unaware of the spacer calculation, they work off a Standard Operating Procedure that was 20 years old. Correct fitting instructions presented and demonstrated. NSK engineers were present during replacement and trained the staff on fitting practices. Genuine NSK bearing replaced the current high cost bearings with significant savings at purchase. Customer standard operating procedure with spacer calculations updated and re issued.

- Steel Industry - Rod Mill Chocks

- Angular Contact Ball Bearings - NSKHPS

Key Facts

- Bearings were incorrect assembled and the staff was not trained

- Old Standard Operating Procedure

- 5 breakdowns per year

- Urgent replacements at high costs

Value Proposals

- Bearings were incorrect assembled and the staff was not trained

- Old Standard Operating Procedure

- 5 breakdowns per year

- Urgent replacements at high costs

Product Features

- Bearings were incorrect assembled and the staff was not trained

- Old Standard Operating Procedure

- 5 breakdowns per year

- Urgent replacements at high costs

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | 8 736 € | Bearing Costs | 3 494 € | |

| Engineering Costs | 655 € | Engineering Costs | 0 € | |

| Costs of lost production | 40 294 € | Costs of lost production | 0 € | |

| Total Costs | 49 685 € | 3 494 € | ||

Reference:SS-E-2-585

Share