Success Story

Industry: Steel & Metals

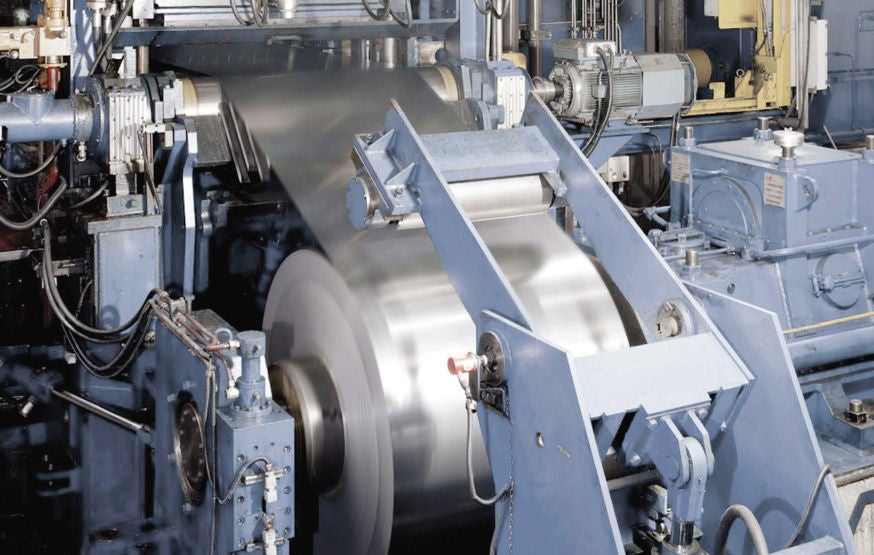

Application: Rolling Mills

Cost Savings: € 270 312

Introduction

In an European steelworks, the back-up rollers of a competitor failed after a short time in the test phase. Initially, the project was awarded to the competition. After multiple failures, NSK engineers were consulted for technical support and proposed to use NSK cylindrical roller bearings with optimised innerring sideswasher for an increased life time. The estimated lifetime is now at over 1,5 years without any failures. This helps to reduce the machine downtime and the maintenance cost drastically.

- Cold Rolling Mill - 20-High Mill

- CRB Double Row - optimised innerring sidewasher

Key Facts

- Cylindrical Roller Bearings for a 20-High Mill

- Existing cylindrical roller bearings failed very short after installation

- NSK proposed to use double row cylindrical roller bearings with optimised innerring sidewasher

- An oil circulation lubrication helps for sufficient lubrication of the bearings

- An approximately lifetime of over 1,5 year is expected

Value Proposals

- Cylindrical Roller Bearings for a 20-High Mill

- Existing cylindrical roller bearings failed very short after installation

- NSK proposed to use double row cylindrical roller bearings with optimised innerring sidewasher

- An oil circulation lubrication helps for sufficient lubrication of the bearings

- An approximately lifetime of over 1,5 year is expected

Product Features

- Cylindrical Roller Bearings for a 20-High Mill

- Existing cylindrical roller bearings failed very short after installation

- NSK proposed to use double row cylindrical roller bearings with optimised innerring sidewasher

- An oil circulation lubrication helps for sufficient lubrication of the bearings

- An approximately lifetime of over 1,5 year is expected

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 456 000 | Bearing Costs | € 250 488 | |

| Engineering Costs | € 6 400 | Engineering Costs | € 1 600 | |

| Costs of lost production | € 60 000 | Costs of lost production | € 0 | |

| Total Costs | € 522 400 | € 252 088 | ||

Reference:SS-E-1-956

Share