Success Story

Industry: Steel & Metals

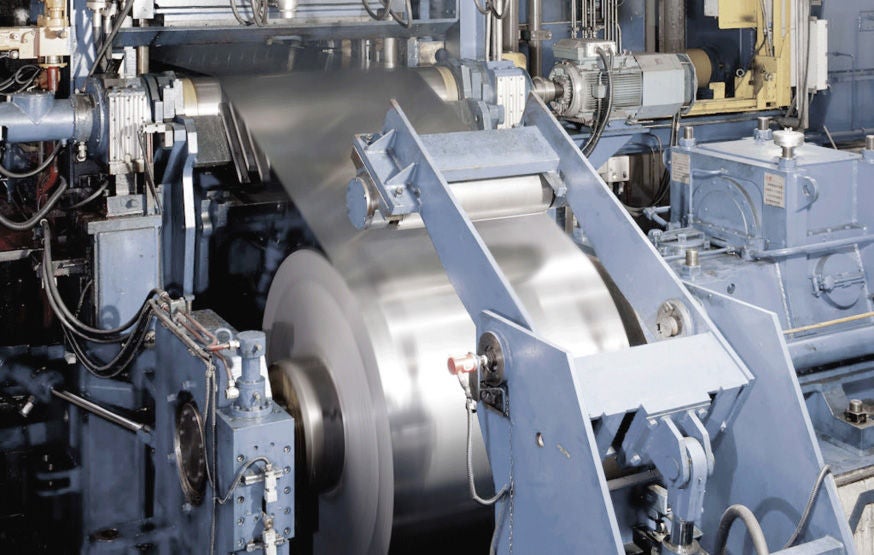

Application: Rolling Mills - Diverter roll

Cost Savings: € 82 312

Introduction

A UK steel manufacturer experienced frequent failures of the bearings in a diverter roll. Unplanned bearing failures often caused the diverter rolls to be scrapped. As a consequence of the seized bearing the product was scored requiring rework or rejection. NSK engineers worked together with the distributor to identify that a change of service caused larger heat transfer to the spherical roller bearings which resulted in degradation of the grease and bearing failure. NSK suggested to use a larger clearance bearing and a high temperature lubrication. As a result the bearing life increased to more than 12 months.

- Cold Rolling Mill

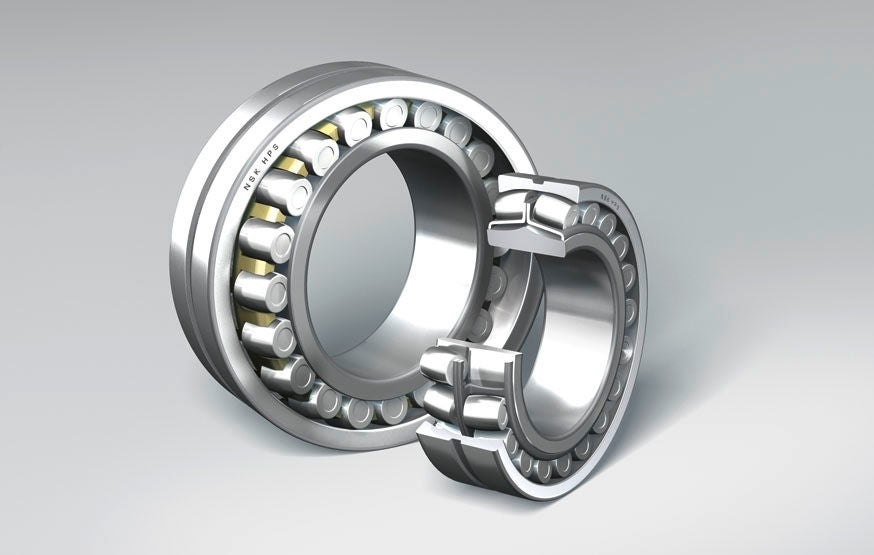

- NSKHPS Spherical Roller Bearing

Key Facts

- Rail rolling mill with a very short bearing life <2 months, failure damaging endproduct

- Heat transfer caused lubricant degradation

- Reduction in clearance and poor lubricant caused seizure

- NSK reviewed the application and the failed competitor bearings

- NSK Solution: Spherical roller bearing with larger clearance and higher temperature capable lubricant

- Bearing life increasing to more than 12 months

Value Proposals

- Rail rolling mill with a very short bearing life <2 months, failure damaging endproduct

- Heat transfer caused lubricant degradation

- Reduction in clearance and poor lubricant caused seizure

- NSK reviewed the application and the failed competitor bearings

- NSK Solution: Spherical roller bearing with larger clearance and higher temperature capable lubricant

- Bearing life increasing to more than 12 months

Product Features

- Rail rolling mill with a very short bearing life <2 months, failure damaging endproduct

- Heat transfer caused lubricant degradation

- Reduction in clearance and poor lubricant caused seizure

- NSK reviewed the application and the failed competitor bearings

- NSK Solution: Spherical roller bearing with larger clearance and higher temperature capable lubricant

- Bearing life increasing to more than 12 months

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 1 635 | Bearing Costs | € 134 | |

| Engineering Costs | € 908 | Engineering Costs | € 0 | |

| Costs of lost production | € 45 420 | Costs of lost production | € 0 | |

| Lubrication Costs | € 5 678 | Lubrication Costs | € 11 | |

| Other Costs: New rollers and reworking product | € 29 749 | Other Costs: New roller | € 933 | |

| Total Costs | € 83 390 | € 1 079 | ||

Reference:SS-E-2-911

Share