Success Story

Industry: Steel & Metals

Application: Steel Tube Making Machine

Cost Savings: € 8 220

Introduction

An important manufacturer of raw steel materials (strip and tubes) was facing issues with standard bearings, mounted in the welding station of a tube making machine. The high temperature of the welding area shortened the bearing life, breaking after short operation and causing continuous production stoppages for bearing replacement. The customer calculated a loss in production of 500 kg of tubes at every stoppage plus partial scrap of actual production. NSK proposed bearings for high temperature environments with special grease. With this solution the customer increased the bearing life. He also established preventive maintenance periods. All These measures led to increased productivity and Elimination of scrap.

- Steel Tube Making Machine

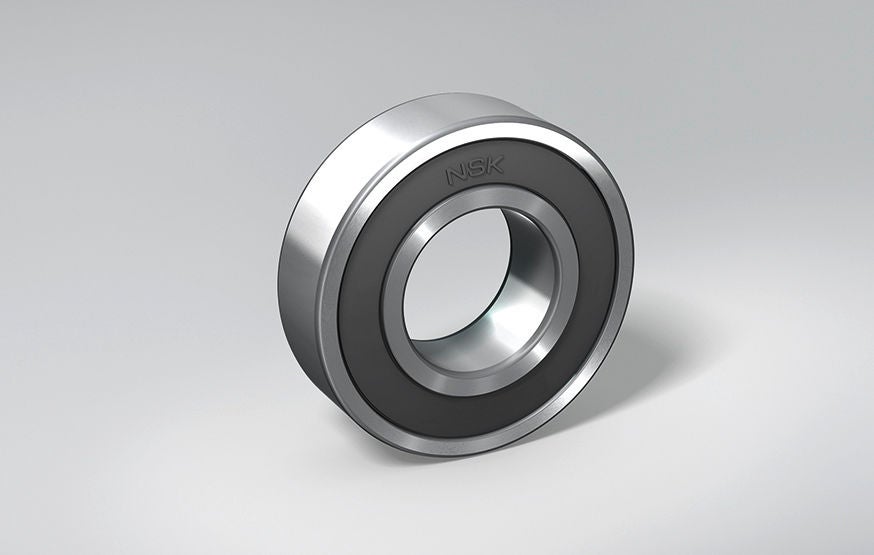

- High Temperature Deep Groove Ball Bearings

Key Facts

- Welding station on steel tube making machine

- Short life of bearings causing production stoppage

- Productivity reduced by 500 kg of tube per stoppage

- Every production stoppage causing partial scrap of actual production

- Temperature of welding area effected life of bearings

- NSK Solution: high temperature Deep Groove Ball Bearings

- Increased bearings life

- Customer was able to start a preventive maintenance programme

- Steel Tube Making Machine High Temperature Deep Groove Ball Bearings

Value Proposals

- The customer explained that each stoppage caused a loss in production

- NSK recommended Deep Groove Ball Bearings for high temperature with a special grease

- A trial with the new bearings showed an increased bearing life

- The successful test resulted in reduced machine downtime and increased productivity

- The customer implemented a regular maintenance programme

Product Features

- Bearing steel heat stabilised to +200 °C

- High temperature Viton seal closures

- High temperature grease +160 °C

- Greater than normal clearance to accommodate bearing ring temperature differentials

- Bearing greased and sealed for life

- Bearing operating temperature +180 °C

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: 6 Bearings set x 15 replacements/year | € 180 | Bearing Costs: 6 Bearings set x 6 replacements/year | € 360 | |

| Costs of lost production: 1h downtime x 100€ labour cost x 15 replacements/year |

€ 1.500 | Costs of lost production: 1h downtime x 100€ labour cost x 6 replacements/year |

€ 600 | |

| Costs of lost production: Productivity loss of 1h x 15 replacements/year | € 7.500 | Costs of lost production: No costs | € 0 | |

| Total Costs | € 9 180 | € 960 | ||

Reference:SS-E-7027

Share