Success Story

Industry: Automotive

Application: Tyre Production

Cost Savings: € 118 642

Introduction

One of the most famous and largest tyre manufacturers in the world experienced bearing failure on rubber cutting machinery. Conventional ball bearing units had many failures (due to harsh conditions – water splash), resulting in premature maintenance at least twice a year plus two unexpected failures per year. NSK performed on Application Review in order to understand operating conditions. The use of Stainless Steel bearing units with Molded-Oil lubricated inserts was proposed to solve the problem caused by corrosion. This solution resulted in 4 times longer bearing life, reduced maintenance, no unexpected bearing failure and no unplanned downtime.

- Tyre Production

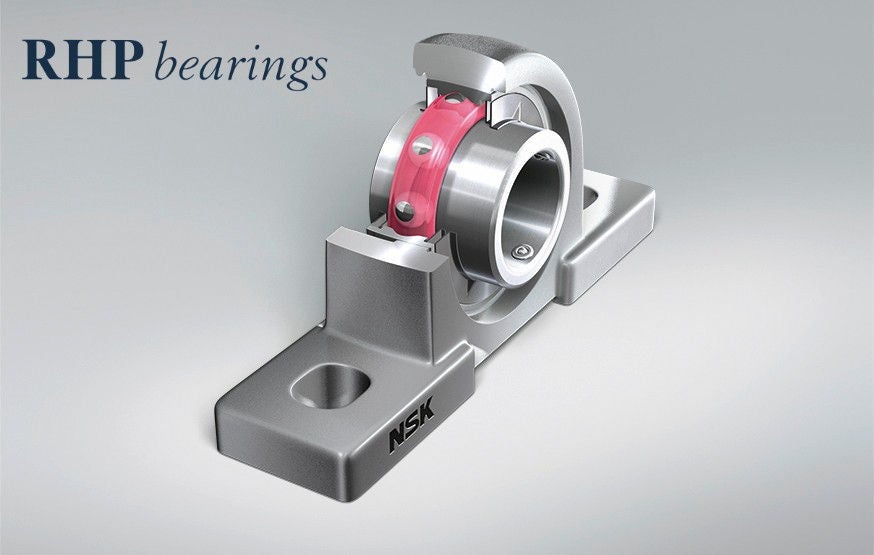

- Stainless Steel Unit with Molded-Oil insert

Key Facts

- Rubber cutting machinery – Tyre production

- Many bearing failures due to harsh ambient conditions

- NSK solution: Stainless Steel Bearing Unit with Molded-Oil insert

- Bearing life extended by up to 4 times

- Reduced maintenance, no unexpected bearing failure and no unplanned downtime

- Cost saving generated

- Tyre Production Stainless Steel Unit with Molded-Oil insert

Value Proposals

- NSK engineers performed on Application Review

- The Bearing Failure Analysis showed failure due to water ingress

- NSK proposed using stainless steel bearing unit with Molded-Oil inserts

- Bearing life extended by up to 4 times

- Reduced maintenance

- No unexpected bearing failure and no unplanned downtime

Product Features

- Longer lubrication life & maintenance free, due to the Molded-Oil insert

- Insert raceways: Martensite stainless steel (equivalent to SUS440C)

- Balls: Martensite stainless steel (SUS440C)

- Flinger: Austenite stainless steel (SUS304)

- Seals: Nitrile

- Set screws (W shape screw head): Martensite stainless steel (SUS410)

- Bearing Housing: Austenite stainless steel casting (SCS13)

- Guards against corrosion (all parts made of stainless steel)

- Maintains a clean environment

- Interchangeable with standard units. 2 shapes available: Pillow and flange

Cost Saving Breakdown

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs: Bearings replacement & grease costs | € 1.068 | Bearing Costs: Bearing costs, no extra lubricant necessary | € 2.506 | |

| Costs of lost production: Bearing mean life: 3 months. 30.000 € for each hour of downtime x hours for bearing replacement x replacements per year |

€ 120.000 | Costs of lost production: Bearings are still running. No downtime caused by bearing failure | € 0 | |

| Engineering Costs: Replacements per year x hours per replacement x 20€ per hour | € 80 | Engineering Costs: No maintenance costs caused by bearing failure | € 0 | |

| Total Costs | € 121 148 | € 2 506 | ||

Reference:SS-E-4001

Share