Başarı Hikayesi

Endüstri: Yiyecek ve İçecek

Uygulama: Bottle Overwrapper

Toplam Maliyet Tasarrufu: € 10 874

Uygulama Geçmişi

A drinks company in the UK were experiencing premature bearing failures due to an unknown reason, believed to be contamination. Bearing lifetime was 1 week. NSK was contacted to evaluate the source of failure. NSK engineers identified the true cause of failure was due to residual magnetism causing Eddie Current Braking. The source of the magnetism could not be changed. Therefore an alternative bearing or design was needed. NSK solution resulted in bearing lifetime increase : from 1 week to 1 year.

- Drinks Bottling Plant

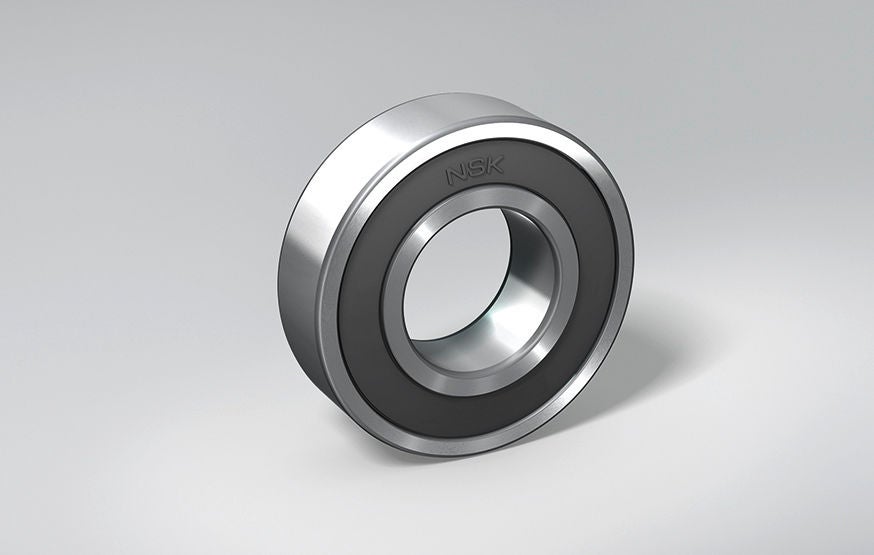

- Deep Groove Ball Bearing with T1X cage

Temel Bilgiler

- Premature bearing failure

- Mass Production, high speed

- NSK Solution : DGBB with T1X cage, C5 clearance and shields

- Increased lifetime x52 times

Değer Önerisi

- NSK Engineers performed Application Review

- Bearing failing due to residual magnetism

- DGBB with T1X cage, C5 clearance and shields

Ürün Özellikleri

- DGBB with T1X cage, C5 clearance and shields

Maliyet Tasarrufu Dökümü

| Önce | Yıllık maliyet | NSK Çözümü | Yıllık maliyet | |

|---|---|---|---|---|

| Rulman maliyeti: Annual bearing cost 3328 x 1.58€ | 5.283 € | Rulman maliyeti: Annual bearing cost 64 x 2,81€ | 180 € | |

| Mühendislik maliyeti: 59€ per hour x 2 people x 52 time per year | 5.772 € | Mühendislik maliyeti | 0 € | |

| Toplam Maliyet | € 11 055 | € 180 | ||

Referans:SS-TR-2086

Paylaş