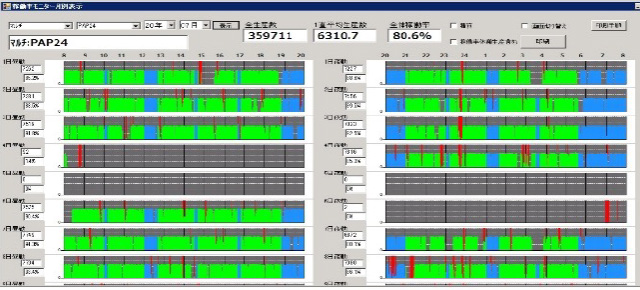

Real-Time Monitoring

Real-time monitoring the production equipment operating status & production quantities to solve the equipment trouble immediately.

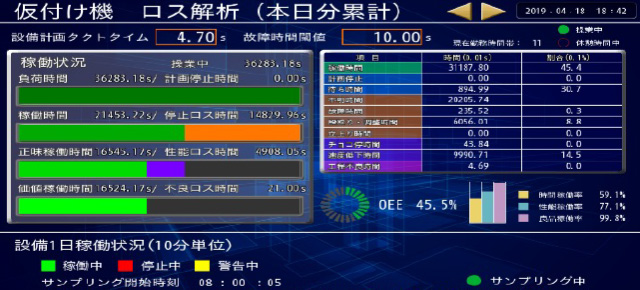

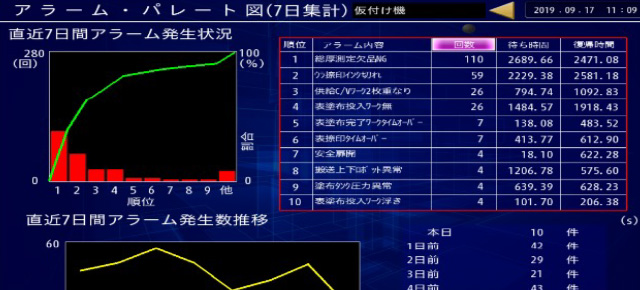

Loss Analysis, Machine Trouble Analysis

Progress daily improvement activities by analyzing down time and machine abnormalities using the “Big data” collecting by “IoT technology”.

Abnormal Sign Monitoring

Enforce the predictive maintenance by abnormal sign monitoring using various sensors attached to the equipment.

Quality Data Collection and Traceability

Achieve advanced traceability by the quality analyzing using collected data of “Quality data of inspection” , “Process flow history” by two-dimensional codes marked on the products.

Working on “Paper-less activity” (Use the tablet computers instead of quality & condition check sheet papers.)