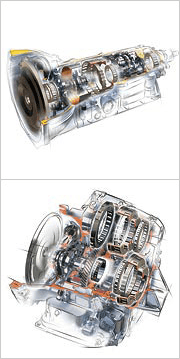

Automatic Transmission

Overview

Automatic transmissions ensure smooth gear changes with minimal shift shock while operating under various kinds of driving conditions. A complex and extremely intricate form of technology known as friction control is ideal for efficiently conveying power from the engine and for smooth gear shifting. Friction-related parts and one-way clutches, which have been developed based on our advanced tribology technology, are the most important products in determining the performance of automatic transmissions. They contribute to a smooth and powerful driving experience.