D-VibA10 Product Details

Flow

- Download the vibration measurement / diagnosis app (ACOUS NAVI for Vibration Diagnostic Devices) from Google Play Store to your Android device.

- Pair the vibration pickup to your Android device via Bluetooth®.

- The vibration pickup is mounted to target rotating machinery to detect vibration and perform diagnostics.

- Detected vibration data is imported into the vibration measurement/diagnostics application via Bluetooth®.

- The app analyzes vibration data, displays individual vibration values and bearing diagnosis results, and stores data and vibration signals for later reproduction (audio playback).

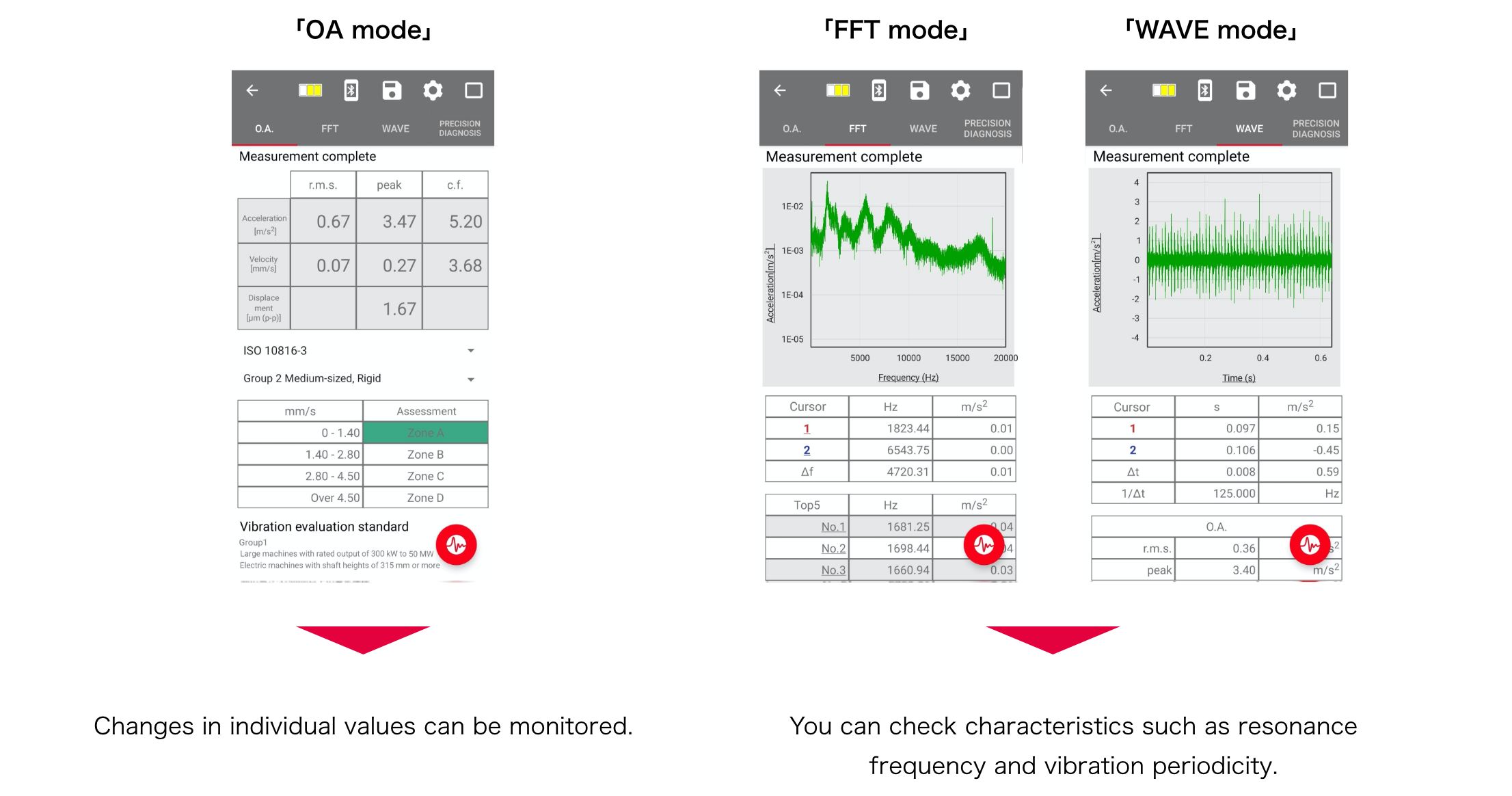

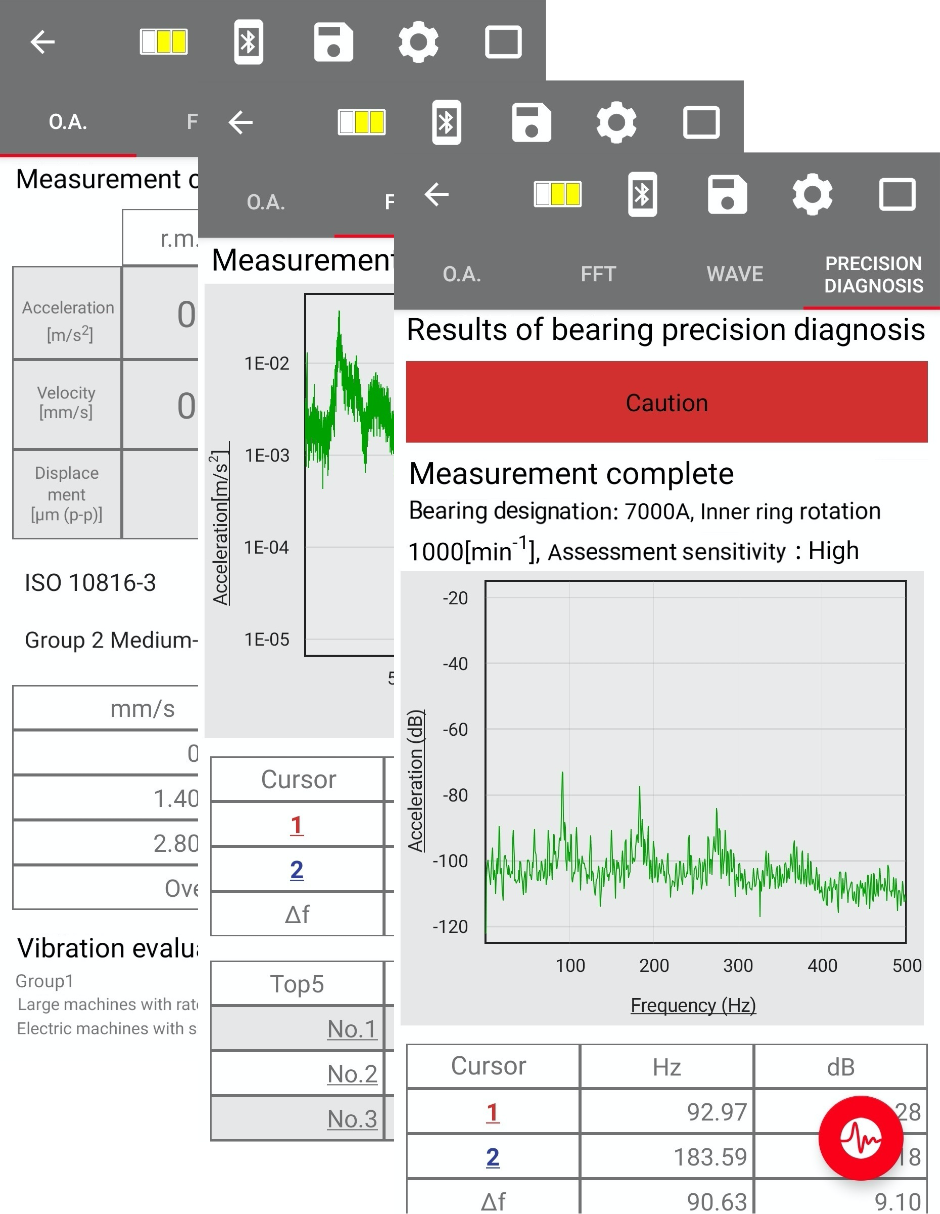

Display Screens

This device features built-in simple vibration diagnostics for monitoring equipment characteristics and general changes and automatic precision diagnostics for bearing flaws and flaking.

Simple diagnostics

You can check the state of vibration and monitor changes in equipment.

- OA mode displays basic vibration parameters.

(Assess vibration severity based on ISO 10816-3) - FFT mode displays frequency analysis results for the vibration acceleration signal

- WAVE mode displays the vibration acceleration signal as a time-axis waveform

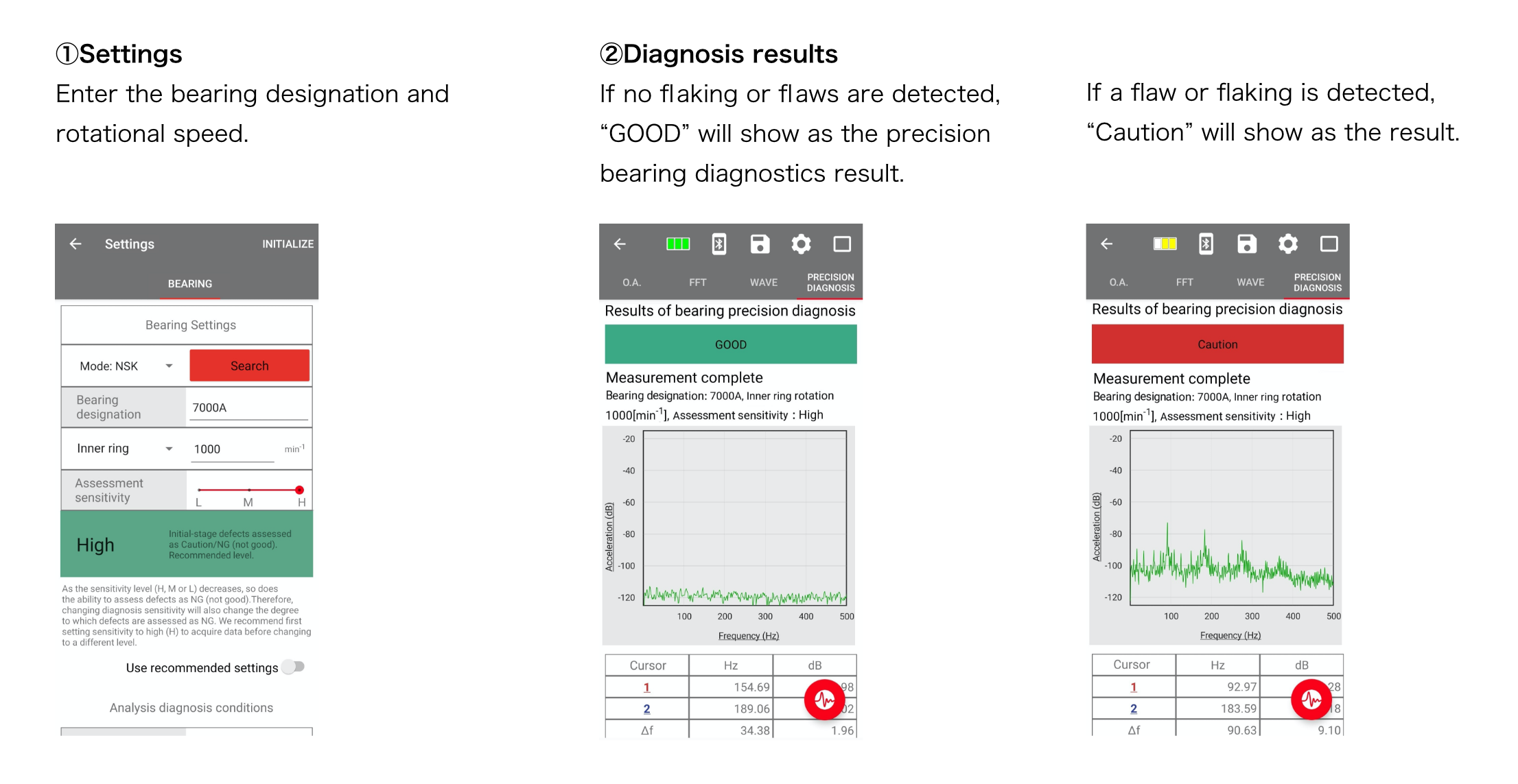

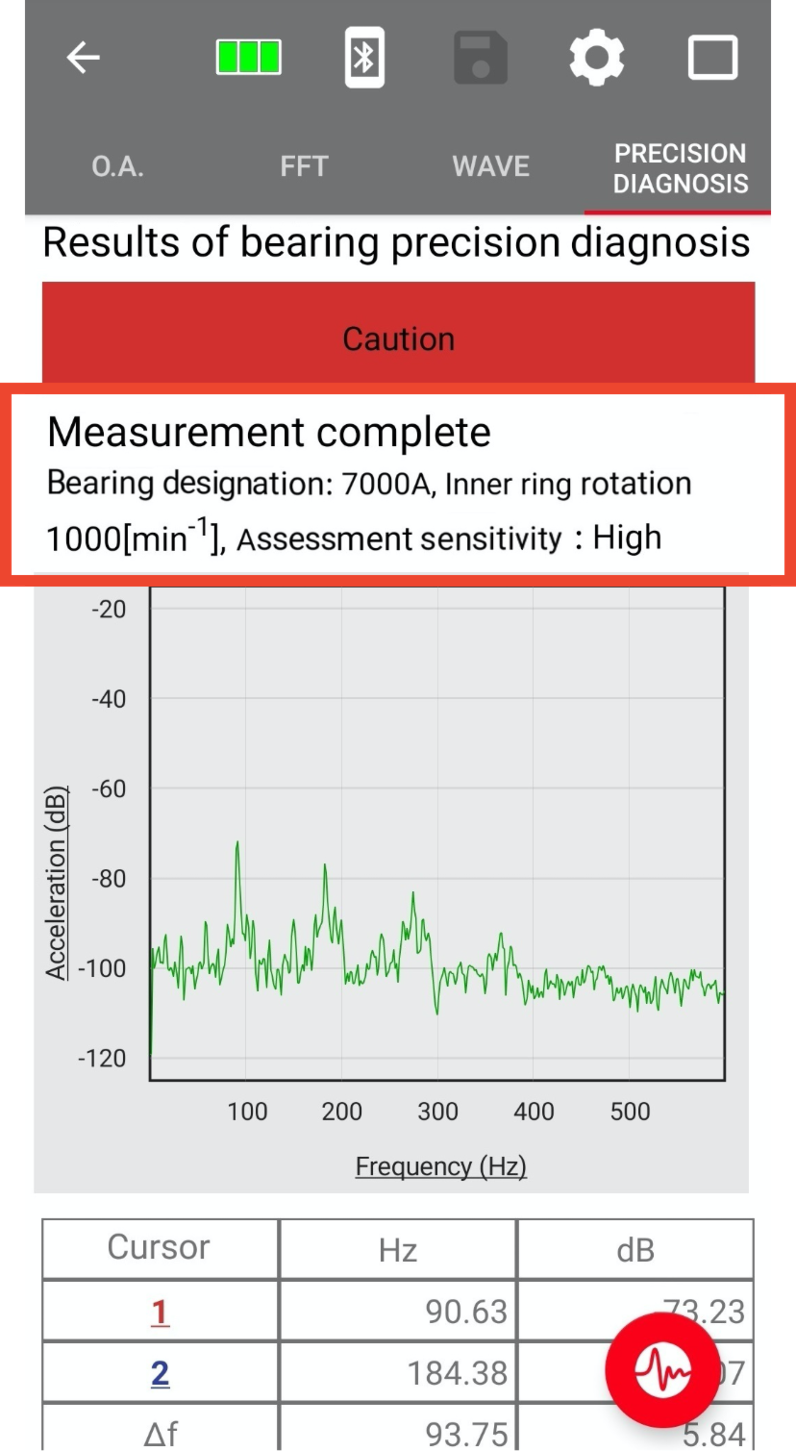

Built-in precision bearing diagnostics: ACOUS NAVI for Bearings

Automatically diagnose bearing flaking and flaws by simply entering the designation and rotational speed of the target bearing.

Lookup entries from a database of over 5000 NSK standard bearings—no complicated calculations or settings required.

* Supports diagnosis of non-NSK bearings through input of the bearing's "pulse generation frequency" as published by the manufacturer.

Customize three sensitivity levels for diagnosis to match the degree of damage that causes problems for a particular machine.

Functions

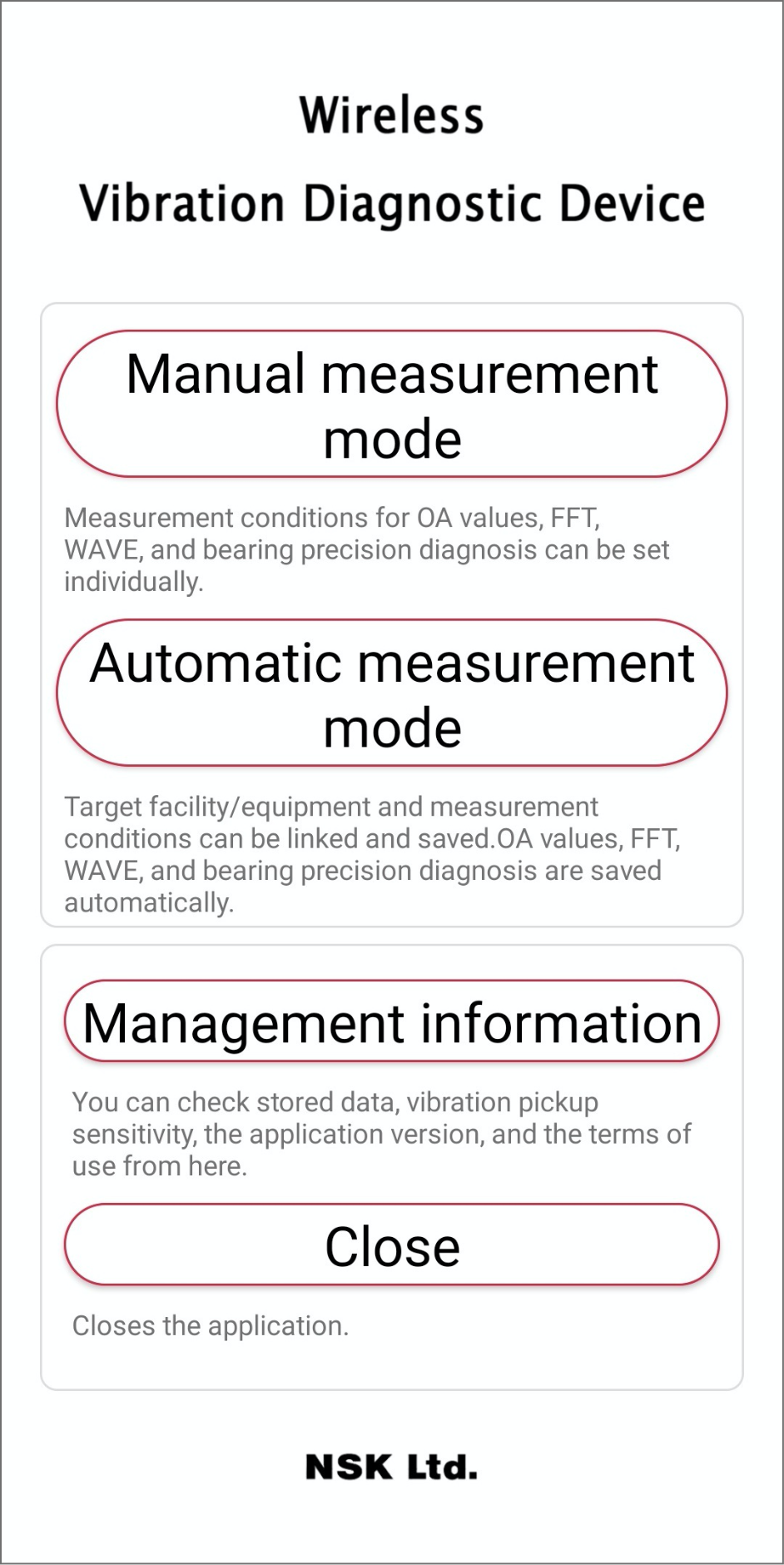

Manual Measurement Mode

Conditions for vibration measurements (OA), frequency analysis (FFT), time domain waveforms (WAVE), and precision bearing diagnosis can be set as desired for individual machines.

Automatic Measurement Mode

NSK's vibration diagnostic device is perfect for regular patrol inspections. In this mode, the device automatically measures vibration (OA), analyzes frequency (FFT), makes a time-domain waveform (WAVE), performs precision bearing diagnosis, and saves all data for future use. In the automatic measurement mode, you only need to set the storage destination and bearing diagnostic conditions before measurement. It only takes about 30 seconds after the start of measurement to obtain vibration analysis and bearing diagnosis results.

Sensitivity Levels for Precision Bearing Diagnosis

Assessments can be performed at three sensitivity levels: High, Medium, and Low.

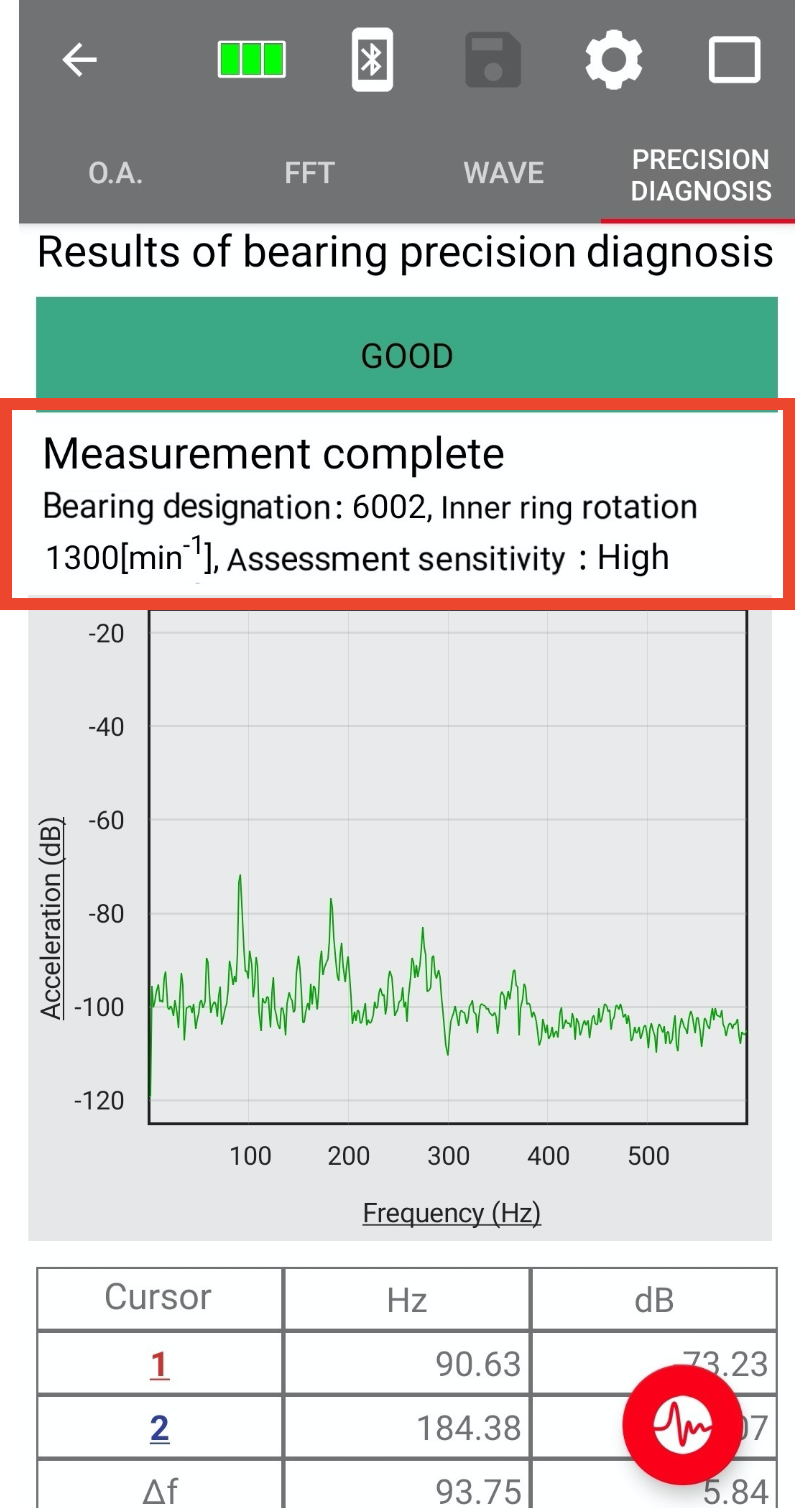

Re-Diagnosis Feature

Easily re-diagnose saved vibration data after changing conditions like bearing designation and rotation speed—no new measurements needed.

Example) Diagnosis of bearing with flaw on the inner ring raceway surface

Bearing designation: 7000A, Inner ring rotation: 1000 min-1

Initial Diagnosis

(Wrong bearing designation and rotation speed)

- Bearing designation: 6002

- Inner ring rotation: 1300min-1

Re-Diagnosis

(Corrected bearing designation and rotation speed)

- Bearing designation: 7000A

- Inner ring rotation: 1000 min-1

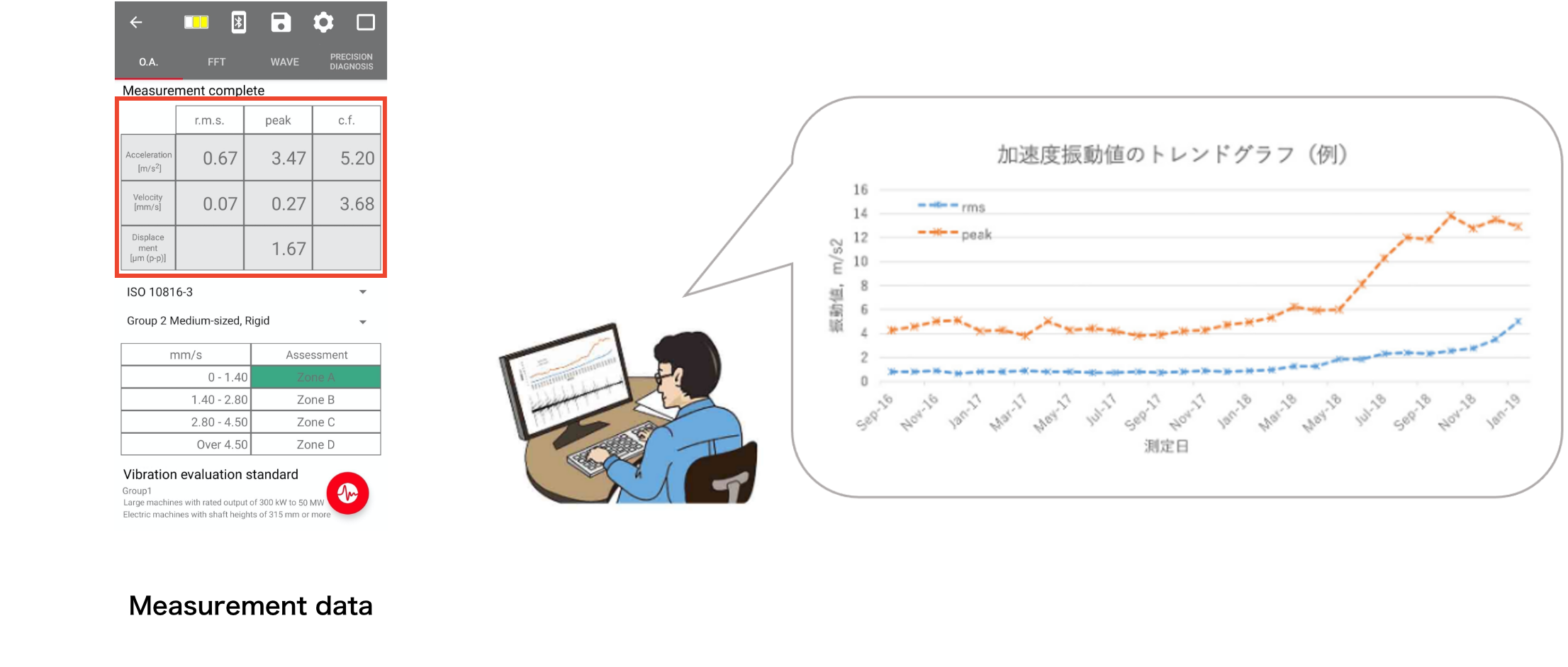

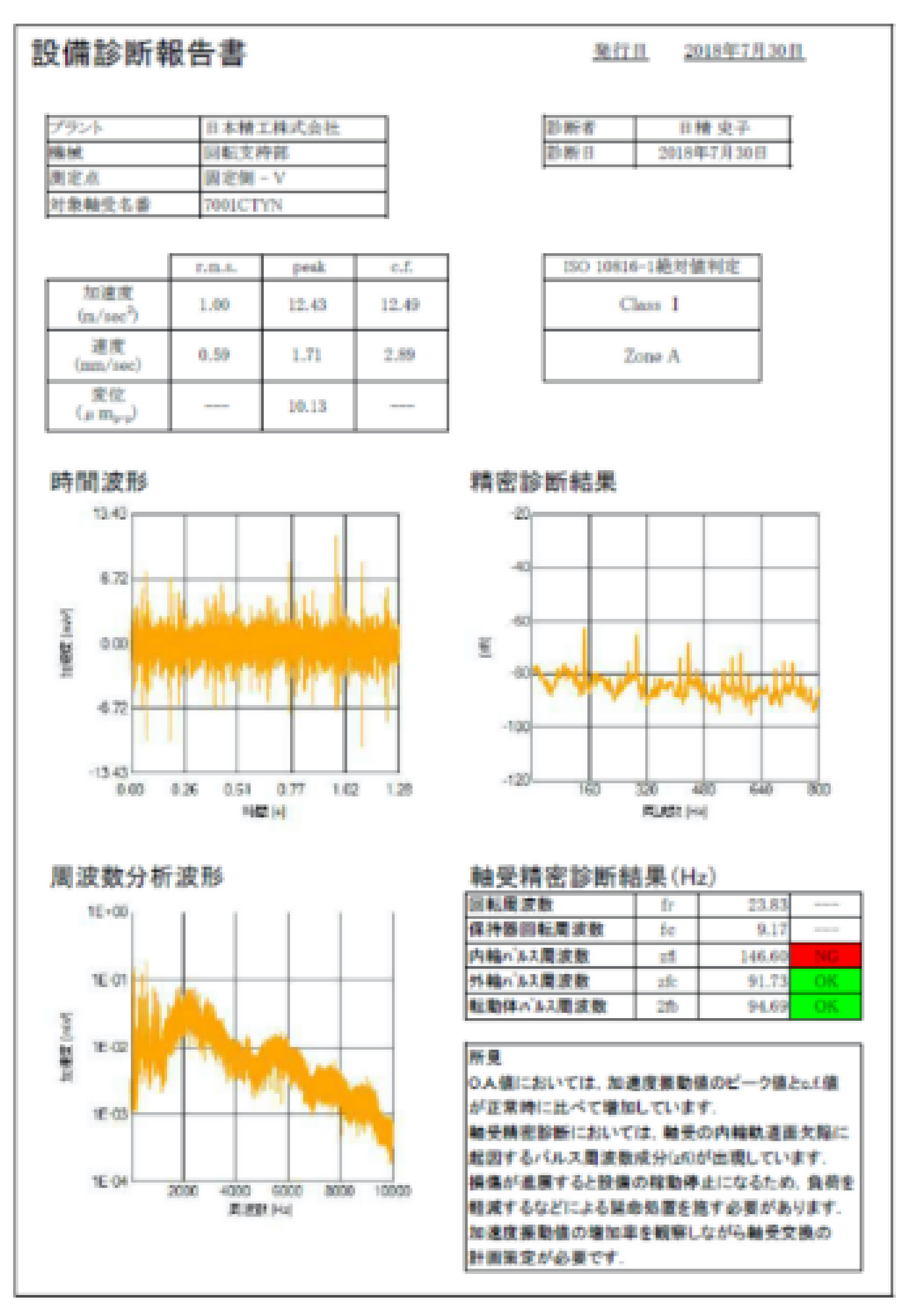

Management Software

The device comes with companion PC software for the following management functions:

- Trend management of data from the app

- Reports on measured and saved data

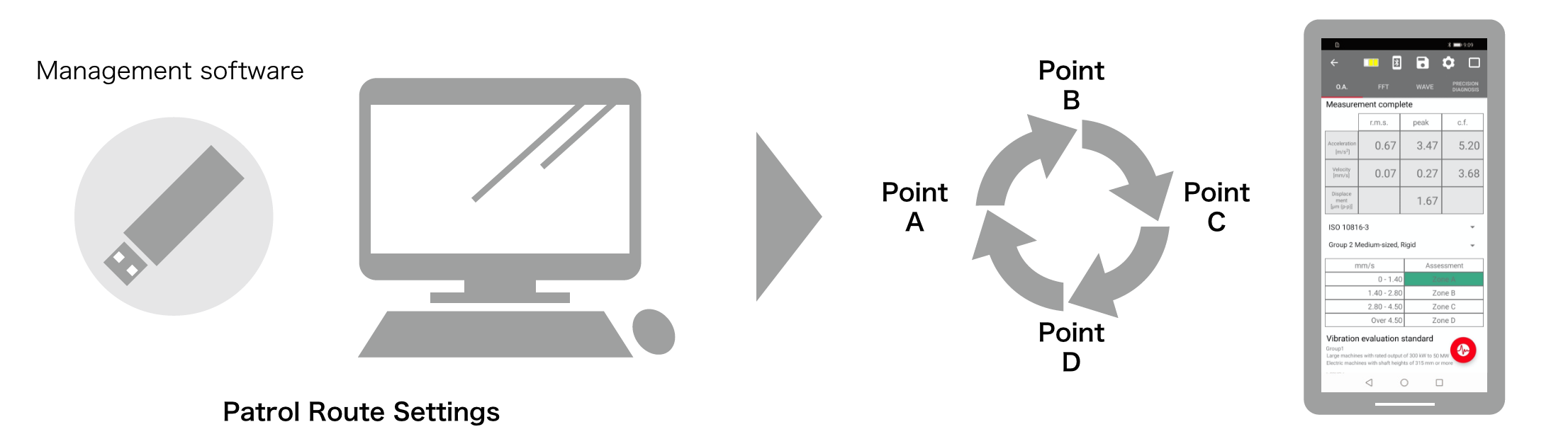

- Patrol Route Settings

Manage data on a Windows PC with companion software on the included USB dongle.

Trend management of measured and saved data

Saved data can be organized by facility, machine, and part, and trends in vibration values can be managed in chronological order.

Creating reports using measured and saved data

Check saved data and select report data for output (Excel format).

Patrol Route Settings

You can set the patrol route on PC and send the data to the app to show measurement points in the specified order and save results.

Benefits

Quantifying sensory testing

Example Customer Issues

- Difficult to determine the state of a machine based on auditory inspections.

- Different operators make different determinations.

Benefits

- Quantify vibration values up to the widest audible band and check on the spot.

- Can check for changes in machine conditions by frequency analysis at the same level as a FFT analyzer.

- ACOUS NAVI for Bearings can automatically determine if bearing abnormalities are present.

Preventing sudden breakdowns and work stoppages

Example Customer Issues

- Can only detect when breakdowns are imminent, even with condition monitoring.

- Repair for sudden breakdowns and failures takes a long time.

Benefits

- During patrol monitoring, the Wireless Vibration Diagnostic Device can detect bearing damage at an early stage, allowing for planned maintenance.

Need for an all-in-one condition monitoring device

Example customer issues

- Unsure of where to start.

- Overwhelmed by number of options.

Benefits

- No complicated equipment necessary! You can measure machine vibration and diagnose bearings from day one with just an Android smartphone.

- Data can be shared across work PCs with the included management software

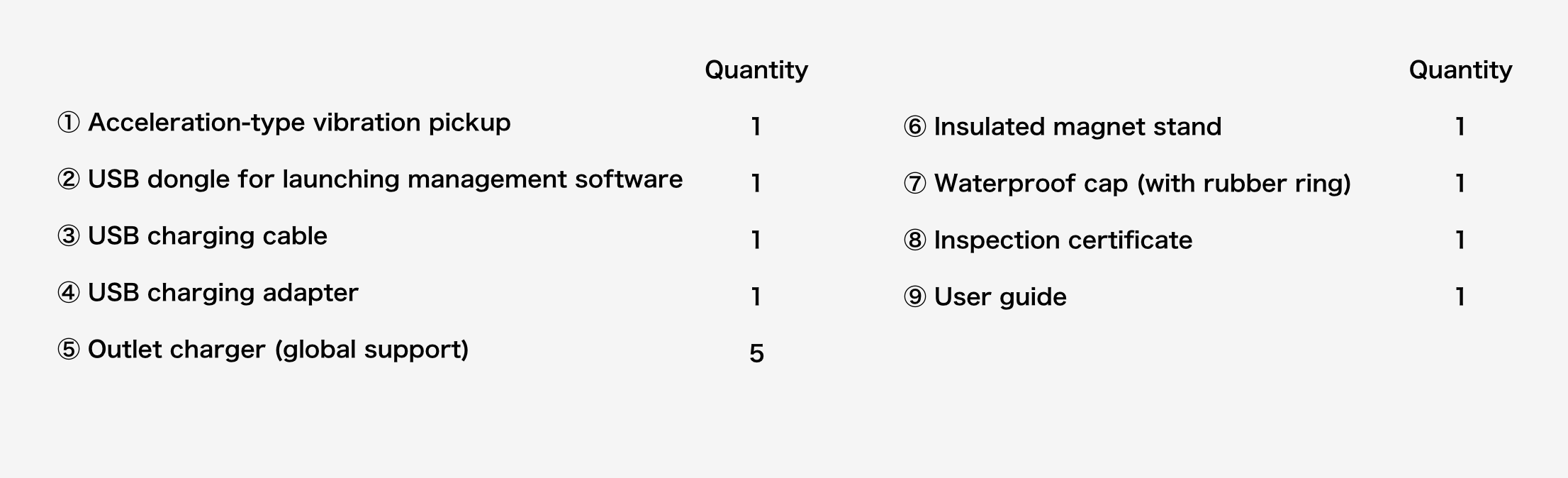

Product contents

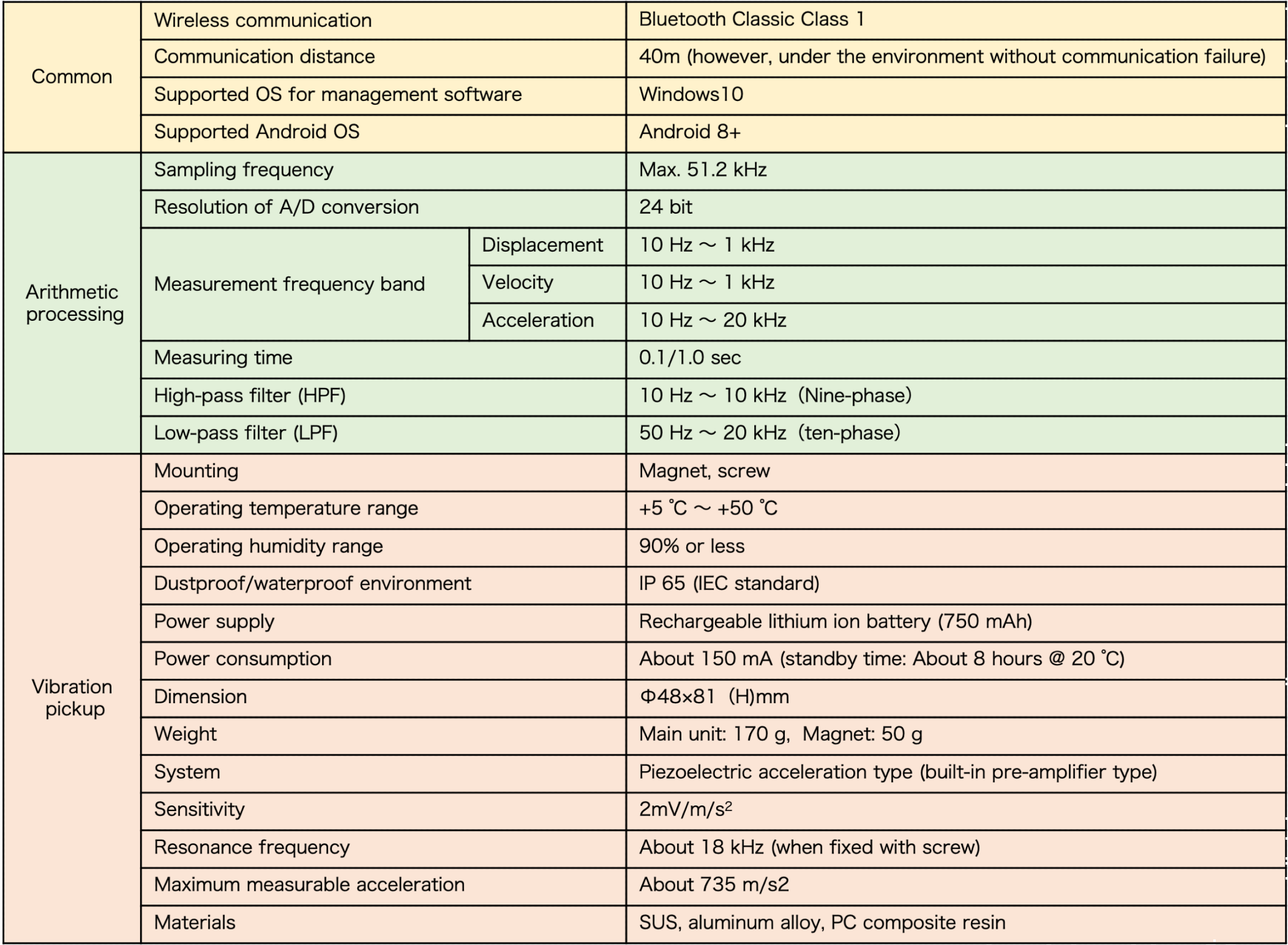

Product specifications

- Please note that the above specifications are subject to change due to product improvements.