After the mounting has been completed, a running test should be conducted to determine if the bearing has been mounted correctly. Small machines may be manually operated to assure that they rotate smoothly. Items to be checked include sticking due to foreign matter or visible flaws, uneven torque caused by improper mounting or an improper mounting surface, and excessive torque caused by an inadequate clearance, mounting error, or seal friction. If there are no abnormalities, powered operation may be started.

Large machines, which cannot be turned by hand, can be started after examination with no load, and the power immediately cutoff and the machine allowed to coast to a stop. Confirm that there is no abnormality such as vibration, noise, contact of rotating parts, etc.

Powered operation should be started slowly without load and the operation should be observed carefully until it is determined that no abnormalities exist, then gradually increase the speed, load, etc. to their normal levels. Items to be checked during the test operation include the existence of abnormal noise, excessive rise of bearing temperature, leakage and contamination of lubricants, etc. If any abnormality is found during the test operation, it must be stopped immediately and the machine should be inspected. If necessary, the bearing should be dismounted for examination.

Although the bearing temperature can generally be estimated by the temperature of the outside surface of the housing, it is more desirable to directly measure the temperature of the outer ring using oil holes for access.

The bearing temperature should rise gradually to the steady state level within one to two hours after the operation starts. If the bearing or its mounting is improper, the bearing temperature may increase rapidly and become abnormally high. The cause of this abnormal temperature may be an excessive amount of lubricant, insufficient bearing clearance, incorrect mounting, or excessive friction of the seals.

In the case of high speed operation, an incorrect selection of bearing type or lubricating method may also cause an abnormal temperature rise.

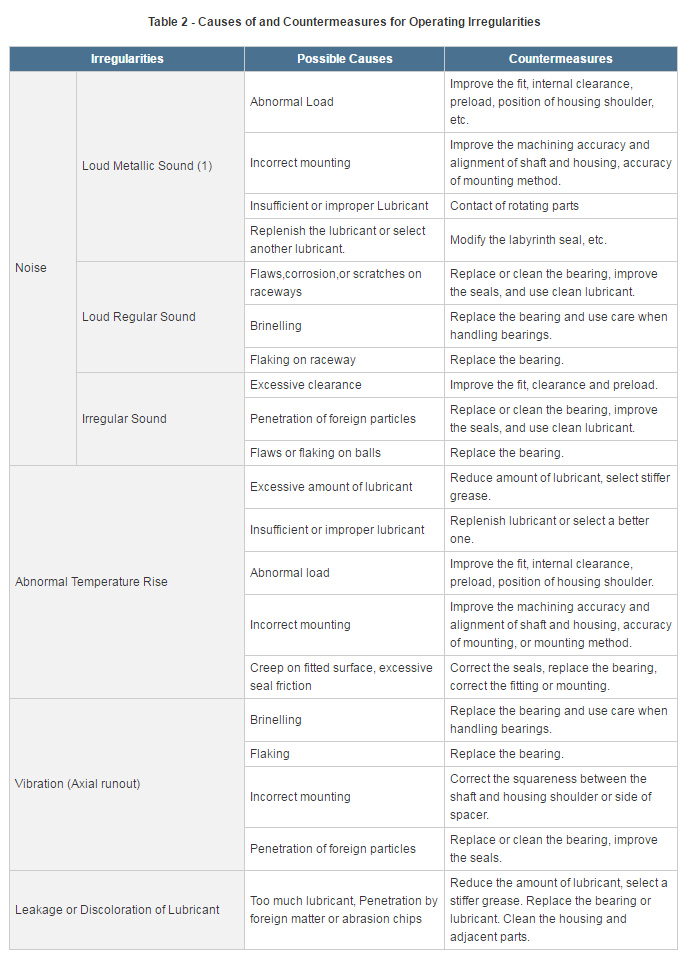

The sound of a bearing may be checked with a noise locater or other instruments. Abnormal conditions are indicated by a loud metallic sound, or other irregular noise, and the possible cause may include incorrect lubrication, poor alignment of the shaft and housing, or the entry of foreign matter into the bearing. The possible causes and countermeasures for irregularities are listed in Table 2.

Note

(1) Intermittent squeal or high-pitch noise may be heard in medium- to large-sized cylindrical roller bearings or ball bearings that are operating under grease lubrication in low-temperature environments. Under such low-temperature conditions, bearing temperature will not rise resulting in fatigue nor is grease performance affected. Although intermittent squeal or high-pitch noise may occur under these conditions, the bearing is fully functional and can continue to be used. In the event that greater noise reduction or quieter running properties are needed, please contact your nearest NSK branch office.

| Related Pages |

|---|